what size drywall screws for 1 2 sheetrock

Latest articles

what size drywall screws for 1 2 sheetrock

...

what size drywall screws for 1 2 sheetrock 【what size drywall screws for 1 2 sheetrock】

Read Morewhat size drywall screws for 1 2 sheetrock

...

what size drywall screws for 1 2 sheetrock 【what size drywall screws for 1 2 sheetrock】

Read MoreEspecially after passivation of galvanized layer, the surface of the oxide layer is thicker and compact, itself has high oxidation resistance. On the other hand, when the surface of the galvanized layer is damaged, exposing the inner iron matrix, because zinc is more active than iron, zinc will bear the role of sacrificing zinc anode, zinc will be oxidized before iron, so as to protect the iron layer will not be damaged.

what size drywall screws for 1 2 sheetrock...

what size drywall screws for 1 2 sheetrock 【what size drywall screws for 1 2 sheetrock】

Read More

what size drywall screws for 1 2 sheetrock

Post time: 18-05-23...

what size drywall screws for 1 2 sheetrock 【what size drywall screws for 1 2 sheetrock】

Read MoreGalvanized wire for welding is generally required to have a certain hardness, after acceptance of galvanized wire, feel is the first thing to do, in addition to the machine test, because the average user does not have testing equipment, on the machine trial is also a very inconvenient way to test. The diameter of electric galvanized wire is measured with a micrometer, and it is kept at about 0.02mm above and below the contract signing standard, with neat appearance, no leakage plating and no messy wire.

what size drywall screws for 1 2 sheetrock...

what size drywall screws for 1 2 sheetrock 【what size drywall screws for 1 2 sheetrock】

Read Morewhat size drywall screws for 1 2 sheetrock

...

what size drywall screws for 1 2 sheetrock 【what size drywall screws for 1 2 sheetrock】

Read Morewhat size drywall screws for 1 2 sheetrock

...

what size drywall screws for 1 2 sheetrock 【what size drywall screws for 1 2 sheetrock】

Read More

what size drywall screws for 1 2 sheetrockCold galvanizing is also called electric galvanizing. It is the use of electrolytic equipment to remove oil, pickling, and then put the pipe into the solution of zinc salt, and connect the anode of the electrolytic equipment, place zinc plate on the opposite side of the pipe, and connect the positive pole of the electrolytic equipment to the power supply. A layer of zinc is deposited on the pipe fitting by directional movement of an electric current from the positive pole to the negative pole. Cold plated pipe fitting is processed before galvanizing.

...

what size drywall screws for 1 2 sheetrock 【what size drywall screws for 1 2 sheetrock】

Read More

what size drywall screws for 1 2 sheetrock“In the booming pet industry chain, pet supplies market occupies a large share, which covers hundreds of categories such as toys, food, clothing and thousands of products.” An industry insider pointed out that the country’s pet supplies market is characterized by a wide variety of products, little competition and huge market potential.

...

what size drywall screws for 1 2 sheetrock 【what size drywall screws for 1 2 sheetrock】

Read More

what size drywall screws for 1 2 sheetrock

Post time: 20-09-22...

what size drywall screws for 1 2 sheetrock 【what size drywall screws for 1 2 sheetrock】

Read More

Popular articles

Post time: 16-03-23- The application range of small hexagonal mesh is also relatively wide, can be used for building wall fixed insulation layer, pipeline, boiler fixed heat preservation, decoration and other fields.

- Wire diameter: 6#–20#, this kind of barbed wire is braided by low carbon steel wire; Aperture: 15′-15′ special standards can be processed according to customer needs. Use: to be used for road beautification with protective net, maintenance and support of seawall, hillside, dam embankment, is a good data to avoid landslides.

Latest articles

-

-

-

-

-

-

Good galvanized wire, plating thickness of 3- 4 mm, zinc adhesion should be less than 460 grams/m, that is, the average thickness of zinc layer is not less than 65 microns. When the thickness of plated parts is greater than 4 mm, the zinc adhesion should not be less than 610 g/m, that is, the average thickness of zinc layer should not be less than 86 microns. Standard galvanized wire coating must be uniform, galvanized layer basically uniform with copper sulfate solution test etching five times no dew iron. For standard galvanized wire coating adhesion requirements, the zinc layer of plated parts should be firmly combined with the basic metal and have enough adhesion strength, after hammer test does not fall off, not convex.

Links

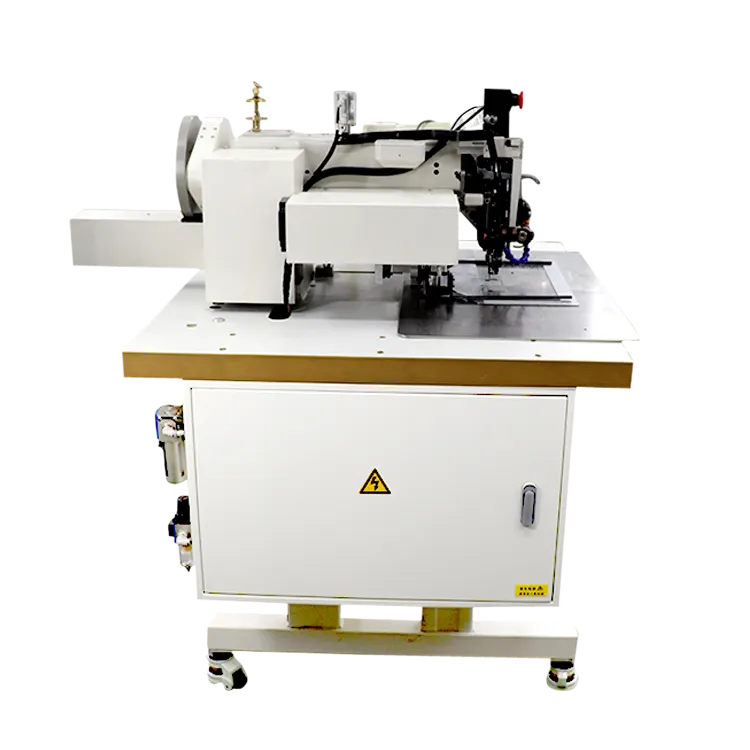

Finding Cylinder Bed Sewing Machines For Sale

Heavy-duty sewing machines are built to withstand the rigorous demands of frequent use. They typically feature a more robust construction compared to standard sewing machines, which allows them to handle thicker fabrics such as denim, leather, and upholstery materials. The powerful motors in these machines provide the strength needed to sew multiple layers and heavy materials without skipping stitches or becoming jammed.

A floating foot sewing machine is a type of sewing machine designed with a unique foot that can glide over various types of fabrics while maintaining consistent pressure. Unlike traditional presser feet, which can sometimes cause fabric bunching or uneven feeding, the floating foot allows for smoother movement, making it ideal for delicate or multiple layers of fabric. This feature is particularly beneficial for quilters, who often work with thick layers of material.

Arm sewing can be used to create a wide range of projects, from simple repairs and alterations to more complex garments and accessories. Whether you are a beginner or an experienced sewer, arm sewing offers a fun and rewarding way to express your creativity and enhance your sewing skills.

3. Consistent Seam Allowances Maintaining a consistent seam allowance is crucial. A variation as small as 1/8 inch can lead to misalignment. Consider using a quarter-inch foot for accuracy, especially in piecing.

One of the key advantages of using a double needle coverstitch is its ability to provide a durable seam that won't easily unravel. Unlike standard sewing techniques that can compromise the integrity of the seam when stretched, the coverstitch uses a combination of straight stitching and chain stitching to absorb tension without breaking. This is particularly important in areas of a garment that experience a lot of wear and movement, such as armholes, waistbands, and hems.