4 gauge welded wire fence panels

Latest articles

4 gauge welded wire fence panels

...

4 gauge welded wire fence panels 【4 gauge welded wire fence panels】

Read More

4 gauge welded wire fence panels

Post time: 08-05-23...

4 gauge welded wire fence panels 【4 gauge welded wire fence panels】

Read More

4 gauge welded wire fence panels

Post time: 20-02-23...

4 gauge welded wire fence panels 【4 gauge welded wire fence panels】

Read More

4 gauge welded wire fence panels1. Used for mountain farming, road isolation, large farming enclosure protection, it is recommended that you choose 3mm wire diameter products.

...

4 gauge welded wire fence panels 【4 gauge welded wire fence panels】

Read More4 gauge welded wire fence panels

...

4 gauge welded wire fence panels 【4 gauge welded wire fence panels】

Read MoreIn general, when exporting and exporting, the blade thorn rope will be packaged and sold, so that the volume occupied in the container is relatively small, which can be easily placed and will not occupy much place.

4 gauge welded wire fence panels...

4 gauge welded wire fence panels 【4 gauge welded wire fence panels】

Read More

4 gauge welded wire fence panelsDifferent from the general zinc barbed rope, high zinc barbed rope surface zinc content is very high can reach the former 6-8 times, so in the service life also has a great advantage, ordinary products three or five years began to corrosion and the latter will take longer to change. Stainless steel barbed rope is in the material aspect of protection, so the durability is also better, these two products are long in the service life, but in the price is high.

...

4 gauge welded wire fence panels 【4 gauge welded wire fence panels】

Read MoreThree is to do a good job of galvanized silk product production site clean and tidy, in accordance with the scientific method of operation to operate the production, the operator should wear the required dress. If it is hot dip galvanized wire products, we must do a good job of passivation treatment, will be able to effectively prevent discoloration, prolong the method of discoloration, can solve the problem of discoloration.

4 gauge welded wire fence panels...

4 gauge welded wire fence panels 【4 gauge welded wire fence panels】

Read More4 gauge welded wire fence panels

...

4 gauge welded wire fence panels 【4 gauge welded wire fence panels】

Read More

4 gauge welded wire fence panelsThere are two kinds of use, namely slope protection hook mesh, coal hook mesh, mining hook mesh, coal mine support network, roadway support network. The height of the outer rail of the pavement or seat belt should not be less than 1.10 m. The net distance between balustrade members shall not be greater than 140 mm, and horizontal rail shall not be used. Hook mesh planning is necessary to be safe and reliable, anchor should be installed on the basis of the railings, its strength should meet the requirements of the standard.

...

4 gauge welded wire fence panels 【4 gauge welded wire fence panels】

Read More

Popular articles

Any application environment, users want a better the strength of the welded wire mesh, only need to improve its intensity, will make better the habit of using demand, but to be improved in the strength of this product, also need to have the condition of many sided, just need to see factory in produce what kind of material, the strength of the product also is the material strength, But a manufacturer does not meet the strength requirements in the data, after all, there is no way to make the strength of the product progress, so this is the necessary condition.

Even so, when they come out, they make trouble, even though they know they will be punished, but they are only in a cage.) If you have time to refer to some foreign dog books, also strongly advocate cage training as a puppy. Before starting cage training, the cage is padded with a water bottle, some fun toys and bones to chew on. The cage door must be opened. Order the dog into the cage, then lure it into its new den with tasty cookies.

Latest articles

-

(4) Stop the use of more than two strands of galvanized iron wire around the operation method.

-

-

Quality standard: Zinc content per square meter has reached or exceeded 122g.

-

Galvanized wire coating has galvanized, aluminum, nylon or plastic coating. Zinc plating is divided into thin coating after steel wire plating and thick coating after steel wire drawing. The mechanical properties of thick coating are lower than that of smooth steel wire rope, and it is suitable for use in serious corrosive environment. Aluminized wire rope it is more resistant to corrosion, wear resistance, heat resistance than galvanized wire rope, using the method of production after the first plating. The wire rope coated with nylon or plastic is divided into two kinds: coated rope and coated rope.

-

The galvanizing process of galvanized wire products is a very effective metal anticorrosion method. It is also widely used in other industrial fields. The use of galvanized iron wire is very common in metal structure equipment of various industries. Due to the influence of production technology or other factors, the zinc layer of galvanized wire products will be different to a certain extent, especially ordinary galvanized can not reach the beauty of electric galvanized, the zinc layer of ordinary galvanized wire is mainly for corrosion prevention.

-

Links

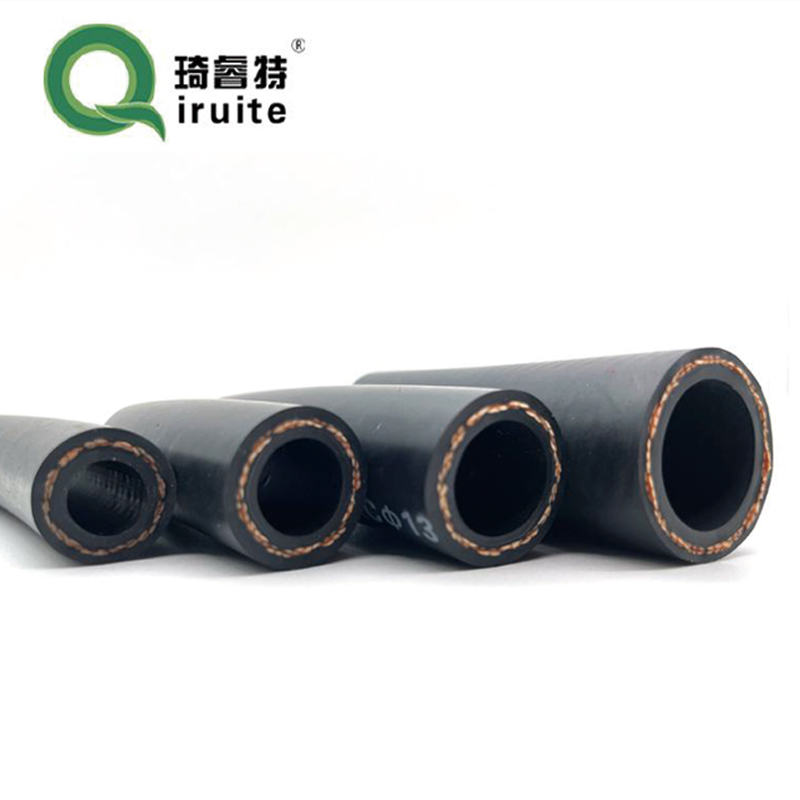

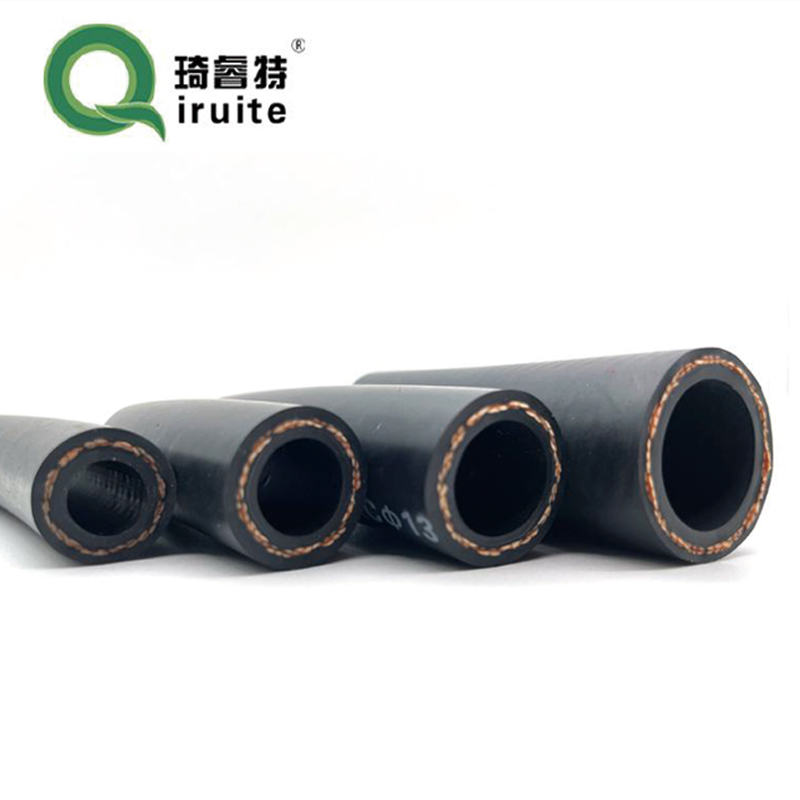

- In the world of automotive engineering, precision and reliability are paramount. One component that significantly contributes to this is the custom high pressure power steering hose. This specialized part plays a pivotal role in ensuring smooth and effortless steering, thereby enhancing the overall driving experience.

However, in recent years, due to cost and environmental concerns, alternatives like aluminum and composite materials have gained traction However, in recent years, due to cost and environmental concerns, alternatives like aluminum and composite materials have gained traction

However, in recent years, due to cost and environmental concerns, alternatives like aluminum and composite materials have gained traction However, in recent years, due to cost and environmental concerns, alternatives like aluminum and composite materials have gained traction air conditioner lines.

air conditioner lines.

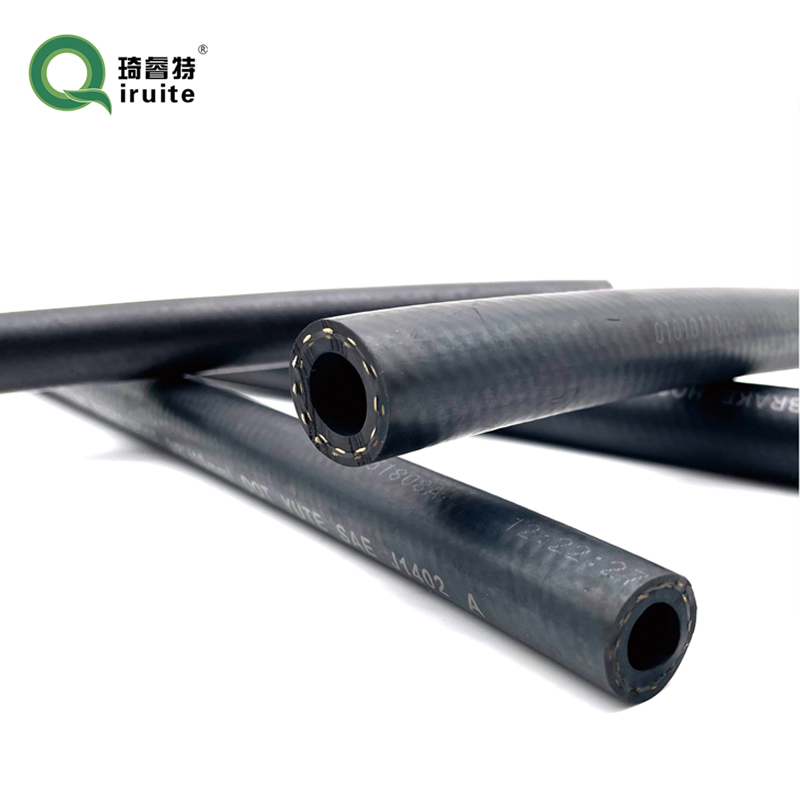

car brake lines. The quality of the brake fluid itself is also vital. Over time, brake fluid can absorb moisture, which can lower its boiling point and cause it to vaporize, leading to 'brake fade'. Regular fluid changes can prevent this.

car brake lines. The quality of the brake fluid itself is also vital. Over time, brake fluid can absorb moisture, which can lower its boiling point and cause it to vaporize, leading to 'brake fade'. Regular fluid changes can prevent this. It is essential to consult your vehicle's owner's manual or a professional mechanic to determine the correct hose for your vehicle It is essential to consult your vehicle's owner's manual or a professional mechanic to determine the correct hose for your vehicle

It is essential to consult your vehicle's owner's manual or a professional mechanic to determine the correct hose for your vehicle It is essential to consult your vehicle's owner's manual or a professional mechanic to determine the correct hose for your vehicle power brake hose.

power brake hose.When selecting hose pipes and connectors, it is important to consider the size and material of the hose, as well as the type of connectors needed for the tasks at hand. For example, a larger diameter hose will allow for a higher flow rate, which is useful for watering large areas quickly. Additionally, connectors made from durable materials such as brass or stainless steel will be more resistant to wear and tear.

Their non-abrasive nature makes them particularly advantageous as they don't damage the substrate being cleaned Their non-abrasive nature makes them particularly advantageous as they don't damage the substrate being cleaned

Their non-abrasive nature makes them particularly advantageous as they don't damage the substrate being cleaned Their non-abrasive nature makes them particularly advantageous as they don't damage the substrate being cleaned hose water jet.

hose water jet. Be sure to support the hose as you remove it to prevent kinking or damage Be sure to support the hose as you remove it to prevent kinking or damage

Be sure to support the hose as you remove it to prevent kinking or damage Be sure to support the hose as you remove it to prevent kinking or damage bmw x5 power steering hose replacement.

bmw x5 power steering hose replacement. Then, as you drag the hose across your flower bed, the guard will prevent it from making direct contact with your plants Then, as you drag the hose across your flower bed, the guard will prevent it from making direct contact with your plants

Then, as you drag the hose across your flower bed, the guard will prevent it from making direct contact with your plants Then, as you drag the hose across your flower bed, the guard will prevent it from making direct contact with your plants hose guards for flower beds. This not only saves your flowers from being crushed but also helps to avoid soil erosion and keeps your garden looking well-groomed.

hose guards for flower beds. This not only saves your flowers from being crushed but also helps to avoid soil erosion and keeps your garden looking well-groomed.

subaru outback power steering hose.

Regular maintenance of these hoses is crucial, as leaks can lead to loss of power steering assistance, making the car harder to control, and potentially causing steering failure Regular maintenance of these hoses is crucial, as leaks can lead to loss of power steering assistance, making the car harder to control, and potentially causing steering failure

Regular maintenance of these hoses is crucial, as leaks can lead to loss of power steering assistance, making the car harder to control, and potentially causing steering failure Regular maintenance of these hoses is crucial, as leaks can lead to loss of power steering assistance, making the car harder to control, and potentially causing steering failure e46 m3 power steering hose.

e46 m3 power steering hose.l2022 In May, Qirui Te was awarded as Safety Production Standardization Level 3 Enterprise (Light Industry);

3 4 inlet hose connector. For instance, some models may have swivel fittings, allowing for easy installation and adjustment, while others incorporate brass inserts for added strength and resistance to pressure. Some even come with rubber O-rings or gaskets to ensure a tight seal and prevent any potential leaks.

3 4 inlet hose connector. For instance, some models may have swivel fittings, allowing for easy installation and adjustment, while others incorporate brass inserts for added strength and resistance to pressure. Some even come with rubber O-rings or gaskets to ensure a tight seal and prevent any potential leaks.

power steering hose crimp fittings. This makes them a popular choice for mechanics and DIY enthusiasts alike. However, it is important to ensure that the fittings are installed correctly and that the crimping process is done with precision to avoid any issues down the line.

Therefore, it's essential to inspect the power steering hose regularly for any signs of damage such as cracks, swelling, or visible leaks Therefore, it's essential to inspect the power steering hose regularly for any signs of damage such as cracks, swelling, or visible leaks

Therefore, it's essential to inspect the power steering hose regularly for any signs of damage such as cracks, swelling, or visible leaks Therefore, it's essential to inspect the power steering hose regularly for any signs of damage such as cracks, swelling, or visible leaks subaru impreza power steering hose.

subaru impreza power steering hose. A leak can result in loss of power steering fluid, which not only affects steering performance but also poses a fire hazard A leak can result in loss of power steering fluid, which not only affects steering performance but also poses a fire hazard

A leak can result in loss of power steering fluid, which not only affects steering performance but also poses a fire hazard A leak can result in loss of power steering fluid, which not only affects steering performance but also poses a fire hazard toyota avalon power steering hose. Regular inspection and timely replacement of worn-out hoses are essential to prevent such issues. Toyota recommends following the manufacturer's maintenance schedule for power steering system checks.

toyota avalon power steering hose. Regular inspection and timely replacement of worn-out hoses are essential to prevent such issues. Toyota recommends following the manufacturer's maintenance schedule for power steering system checks.lIn September 2010, Qirui Te was awarded the honorary title of Outstanding Contribution Unit in Support of Education Development;

split ac water outlet pipe price. Some brands are known for their high-quality materials and construction, which can drive up the cost of the pipe. However, there are also budget-friendly options available that provide good quality at a lower price point.