welded steel wire panels

Latest articles

welded steel wire panelsGalvanized hexagonal net is a kind of galvanized metal wire mesh, mesh shape is hexagonal.

...

welded steel wire panels 【welded steel wire panels】

Read Morewelded steel wire panels

...

welded steel wire panels 【welded steel wire panels】

Read Morewelded steel wire panels

...

welded steel wire panels 【welded steel wire panels】

Read MoreZinc coating on steel and ferrous metal plays an anodic role, it is commonly used for those parts subjected to atmospheric or water action, but zinc coating only when the water temperature below 60℃, the anode properties. When the temperature is higher, the potential changes and the zinc to iron becomes the cathode. Therefore, for parts subjected to hot water (such as steam boilers), the zinc skeleton must be approximately 70 microns thick and void free. For parts subjected to low or normal temperature or atmospheric action, zinc coating without pinholes is not necessary.

welded steel wire panels...

welded steel wire panels 【welded steel wire panels】

Read MoreThe management system of the rinsing water after wire pickling should be discharged regularly and regularly, and the rinsing water should be kept clean and low acid value as far as possible. It is more appropriate to control the pH value of 3. The concentration of plating aid should not be too high. The hot plating wire must be added with ammonium chloride and zinc chloride according to the data of laboratory analysis, and the specific gravity of the composite solution is controlled within the range of 50~80g/L. If ammonium chloride or zinc chloride is added without reference to the results of laboratory analysis, it should be criticized and educated, and economic treatment should be given if necessary.

welded steel wire panels...

welded steel wire panels 【welded steel wire panels】

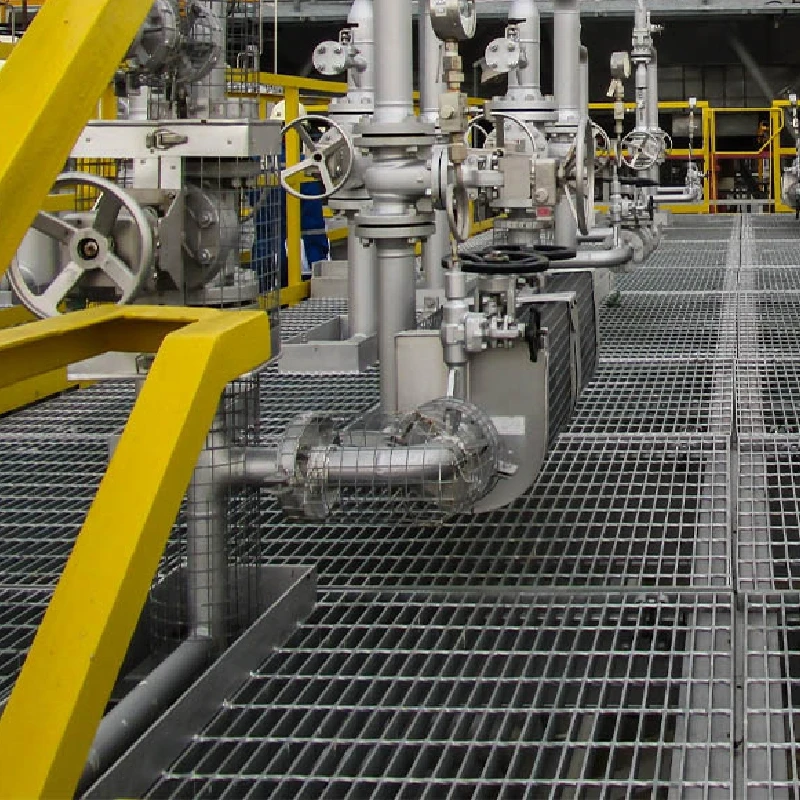

Read MoreApplication: Building materials

welded steel wire panels...

welded steel wire panels 【welded steel wire panels】

Read Morewelded steel wire panels

...

welded steel wire panels 【welded steel wire panels】

Read Morewelded steel wire panels

...

welded steel wire panels 【welded steel wire panels】

Read More1. Put the cat carefully in the special basin for washing the cat. Keep your cat as calm as possible.

welded steel wire panels...

welded steel wire panels 【welded steel wire panels】

Read More

welded steel wire panelsMost of the production enterprises or large public places, they can play a defense hook mesh in the choice of time, often will hook mesh quality in position, so galvanized hook mesh this product few people are interested in, but does this show that galvanized hook mesh is not useful?

...

welded steel wire panels 【welded steel wire panels】

Read More

Popular articles

Annealing wire is widely used because it has a good elasticity and flexibility, in the annealing process can be good control of its hardness, it is mainly made of iron wire, more often used in the construction industry binding wire use. In the production of the wire factory, annealing wire will be processed according to the properties of the material, according to the needs of different to change its hardness degree, can make it has more advantages, can reduce the consumption of metal, reduce the cost of production.

1. Principle. Because zinc does not change easily in dry air, and in humid air, the surface can form a very dense film of zinc carbonate, which can effectively protect the interior from corrosion. And when the coating is damaged for some reason and the matrix is not too large, the zinc and steel matrix form a micro cell, so that the fastener matrix becomes the cathode and is protected. It is widely used in automobile transportation and other industries, but what is needed is the trivalent chromium passivation layer, zinc nickel alloy plating closed coating, reduce the harmful and toxic layer of hexavalent chromium passivation.

Coping methods we also have: 1, gouging, the straight wire rolled into a wavy shape, but still not enough to raise chickens with mesh can only be large enough to extend the beak can not feed! 2, is the electric welding net, with the current to wire spot welding together, mesh is not limited.

Latest articles

-

The form of installation: in the top with the various cage tied together at least as wrapped stone cage net that combination closely not easy to use bad. If the local bandaging is appropriate, it can increase the stability of the structure. There are a lot of grid edge, if the stone cage net only hook in the cage edge and not prepared in the cage edge, even in loose.

-

-

4, galvanized can be used zincate galvanized or chloride galvanized process, should use appropriate additives to meet the requirements of this standard coating.

-

3. The structure of the dog cage should be reasonable

-

-

Now hexagonal net is widely used in the protection of bridge, pier and bridge buttress inclined plane, there are many kinds of bridge buttress inclined plane, people choose the right hexagonal net according to the inclination of the inclined plane, when the inclined plane is gentle, people generally use gabion slope protection system, and in the case of steep slope, people will use gabion mesh gravity protection wall.