window metal screen mesh

Latest articles

window metal screen mesh

Post time: 07-06-22...

window metal screen mesh 【window metal screen mesh】

Read More

window metal screen mesh

Post time: 24-02-23...

window metal screen mesh 【window metal screen mesh】

Read Morewindow metal screen mesh

...

window metal screen mesh 【window metal screen mesh】

Read Morewindow metal screen mesh

...

window metal screen mesh 【window metal screen mesh】

Read More

window metal screen meshGalvanized hexagonal net uses: building wall fixing, heat preservation, heat insulation; Power plant piping, boiler insulation; Anti-freezing, residential protection, landscaping protection; Raise chickens and ducks, isolate chicken and duck houses, protect poultry; Protect and support seawalls, hillsides, roads, Bridges and other water and wood works.

...

window metal screen mesh 【window metal screen mesh】

Read Morewindow metal screen mesh

...

window metal screen mesh 【window metal screen mesh】

Read More

window metal screen meshWhen using these two products, it is obvious that there is a gap between them. By pulling or bending the wire, it is often difficult to restore the original, for example, if the same place is repeatedly bent, it will be found that it has broken, and the cold drawing wire will not. Cold drawing wire compared with iron wire, its hardness, tensile resistance, bending ability is greatly enhanced, suitable for building materials.

...

window metal screen mesh 【window metal screen mesh】

Read More

window metal screen meshNow many hardware manufacturers produce iron wire, and iron wire is very easy to rust, if you need to use in outdoor or humid places, generally customers will require the use of galvanized iron wire equipment to give the wire a layer of zinc, the thickness can be determined according to user requirements. Galvanized iron wire equipment is specially used for the plating of iron. Generally speaking, the stability of zinc is much higher than that of iron, and it will not rust in the daily water vapor or damp place.

...

window metal screen mesh 【window metal screen mesh】

Read Morewindow metal screen mesh

...

window metal screen mesh 【window metal screen mesh】

Read Morewindow metal screen mesh

...

window metal screen mesh 【window metal screen mesh】

Read More

Popular articles

- Some herdsmen avoid the intrusion of wild animals and other people’s livestock and from time to time to increase the grassland grassland stainless steel barbed rope fence net, so that the grassland grassland stainless steel barbed rope fence net has become a barrier to all kinds of wild animals. It is in herders’ interests to increase the number of their livestock, but consciously raising barbed ropes not only directly frightens and harms wildlife, but also cuts them off from food and migration.

- Hexagonal net Uses: Used for raising chickens, ducks, geese, rabbits and zoo fences, construction industry wall batching net, daub wall net. Road green belt protection net.

- Hexagonal mesh is also known as twisting mesh, thermal insulation net, soft edge net. It is made of single – layer mesh. Its mesh, mesh wire, galvanized and PVC film properties and the same as the cage. This product can be different shapes and sizes of the block stone into the alloy net to form a flexible whole, through lifting, car, shipping to the place, the alloy net connected to each other into a larger whole, construction throwing convenient, fast, good economic performance.

- (2) The construction is simple and does not need special technology;

Latest articles

Links

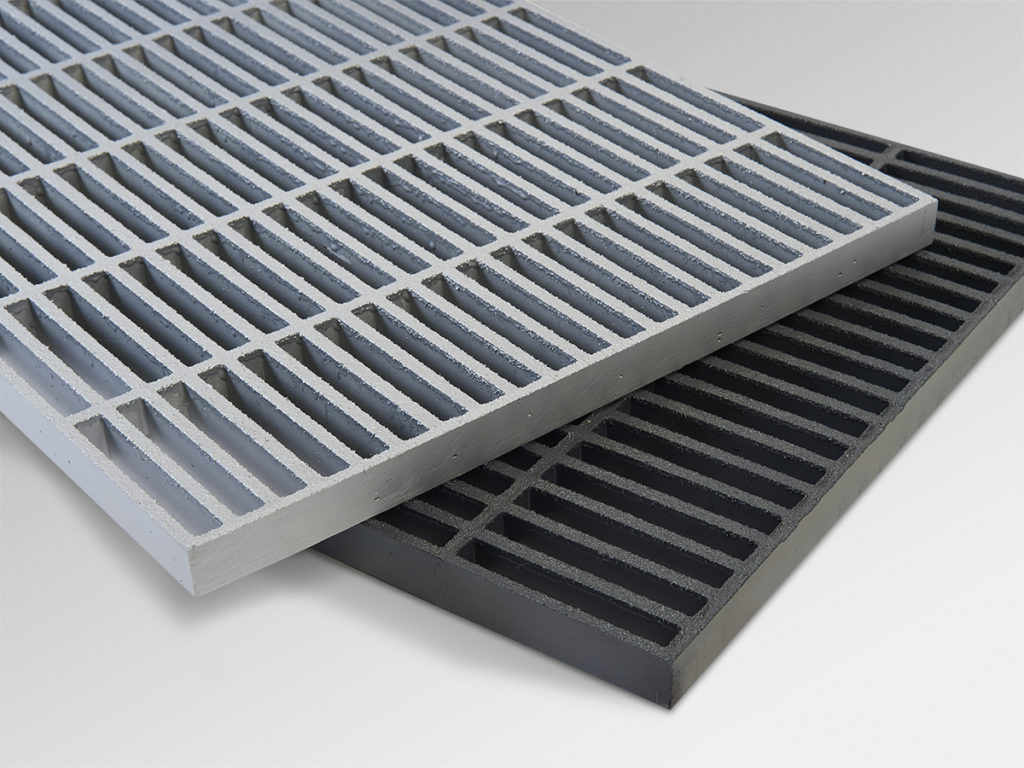

- Furthermore, GRP ladder systems, walkways, and platforms provide safe and sturdy access points within the plant, resistant to both corrosion and slip, ensuring worker safety in hazardous environments. GRP gratings, with their open-grid design, allow for efficient ventilation and easy cleaning, contributing to a cleaner and safer workplace.

For example, they can be used to remove old grout or plaster from walls and ceilings, or to break up frozen ground before excavation For example, they can be used to remove old grout or plaster from walls and ceilings, or to break up frozen ground before excavation

For example, they can be used to remove old grout or plaster from walls and ceilings, or to break up frozen ground before excavation For example, they can be used to remove old grout or plaster from walls and ceilings, or to break up frozen ground before excavation Its open-grid design allows for water and debris passage, ensuring a safe walking surface Its open-grid design allows for water and debris passage, ensuring a safe walking surface

Its open-grid design allows for water and debris passage, ensuring a safe walking surface Its open-grid design allows for water and debris passage, ensuring a safe walking surface