expanded metal 4 x 8

Latest articles

expanded metal 4 x 8

Post time: 01-07-22...

expanded metal 4 x 8 【expanded metal 4 x 8】

Read Moreexpanded metal 4 x 8

...

expanded metal 4 x 8 【expanded metal 4 x 8】

Read Moreexpanded metal 4 x 8

...

expanded metal 4 x 8 【expanded metal 4 x 8】

Read More

expanded metal 4 x 8Stainless steel blade barbed rope production process is basically similar to galvanized blade barbed rope production process, usually according to the mold to determine the size of the blade.

...

expanded metal 4 x 8 【expanded metal 4 x 8】

Read More

expanded metal 4 x 8

Post time: 27-07-22...

expanded metal 4 x 8 【expanded metal 4 x 8】

Read MoreThe application range of small hexagonal mesh is also relatively wide, can be used for building wall fixed insulation layer, pipeline, boiler fixed heat preservation, decoration and other fields.

expanded metal 4 x 8...

expanded metal 4 x 8 【expanded metal 4 x 8】

Read More

expanded metal 4 x 8Select cut silk first to ensure that the raw material of the silk is exactly the raw material you need, the raw material will be used well. Choose high straightness, so that the length of the truncation will be the same, will not show a lot of length difference, the length of the truncated wire is a very important element to choose the truncated wire.

...

expanded metal 4 x 8 【expanded metal 4 x 8】

Read MoreHard black galvanized iron wire is made of low carbon steel wire directly drawn by drawing machine. The primary characteristics of hard black galvanized iron wire are high hardness and bright appearance. Primary use for welding hanger, umbrella, metal mesh, basket, basket and other metal products. Soft black galvanized iron wire is made of low carbon steel wire after annealing and softening, and then cold drawn. The primary feature of soft black galvanized iron wire is good flexibility, slightly higher hardness, bright appearance. Mainly used for metal mesh weaving process, electric welding mesh, welding process products.

expanded metal 4 x 8...

expanded metal 4 x 8 【expanded metal 4 x 8】

Read MoreEvery part of the plating can be zinc plated, even in dents, sharp corners and hidden places can be fully maintained. The cost of hot dip galvanized rust prevention is lower than that of other paint coatings. The galvanizing process is more convenient than other coating construction methods, and can prevent the time required after the device is painted on the site. In suburban environment, the standard hot-dip galvanized rust prevention thickness can adhere to more than 50 years without repair. In urban or offshore areas, the standard hot-dip galvanized rust protection layer can last 20 years without repair.

expanded metal 4 x 8...

expanded metal 4 x 8 【expanded metal 4 x 8】

Read More

expanded metal 4 x 8

Post time: 01-03-23...

expanded metal 4 x 8 【expanded metal 4 x 8】

Read More

Popular articles

Paint on the galvanized layer, the binding force between each other and the baking temperature of the paint has a great relationship, after galvanized coating alkyd paint, adhesion is no problem. Galvanized amino paint, paint adhesion is not good. Do two bottom two surface, adhesion is ok, if the two bottom two surface to two bottom three surface, that is, more paint, more baking once, again test adhesion is very poor, poor to the paint from the galvanized layer of pieces torn off.

The lighting surface of each type of shed is designed to be curved, improving the Angle of the light surface, because the lighting surface is curved, no dust accumulation, good light transmittance, high temperature in the shed, after measurement, the average temperature in the shed is 3℃ higher than the traditional bamboo pole cement column shed, the yield is increased by 15~20%, and the harvest date is advanced. The formula is scientific, the surface does not absorb moisture, do not return halogen through modification technology and scientific production process, solve the greenhouse frame rod is easy to absorb moisture return halogen, poor water resistance and easy to change the shortcomings, so that the greenhouse steel pipe in the high temperature and high humidity environment, few drops, frost phenomenon, and reduce pests and diseases.

Latest articles

-

-

-

Post time: 07-11-22 -

Unless the stainless steel blade barbed rope is specially customized, it is usually produced by the mould with the knife length of 22mm, which is the BTO-22 type we usually call. This is not necessarily the specification from 11mm to 65mm are specifications. Unless the customer insists on customized length requirements, the barbed rope manufacturer will produce BTO-22 stainless steel blade barbed rope.

-

-

The application of electric welding mesh is more and more widely, the technology is gradually mature, electroplating rust prevention, plastic coated treatment, used for breeding, grille, plus the frame to make a fence, etc.

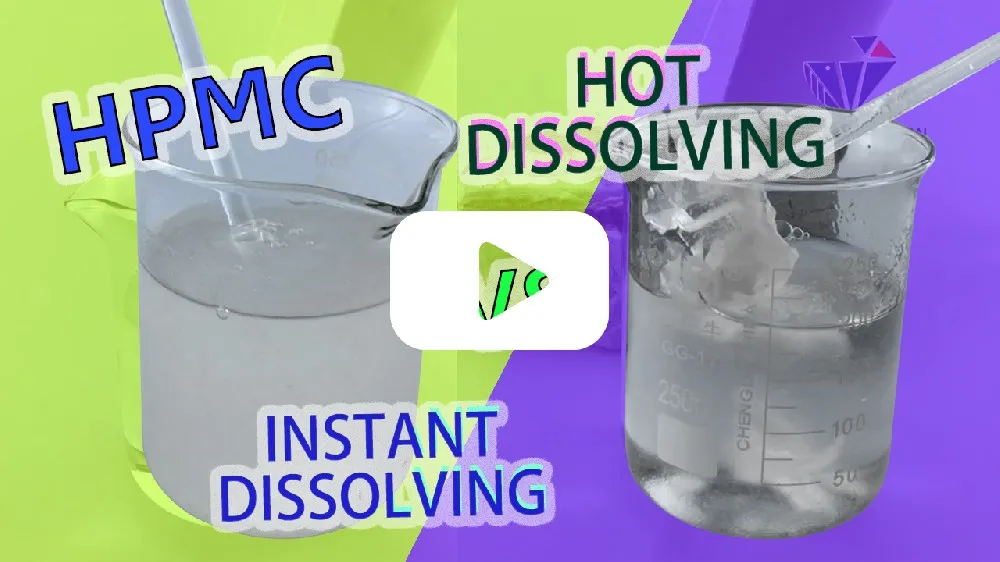

HPMC is extensively used in the food industry as a thickening agent, stabilizer, and emulsifier. It enhances the texture and consistency of various food products, including sauces, dressings, and baked goods. In the pharmaceutical sector, HPMC is favored for its use in drug formulations, particularly in controlled-release medications and as a binder in tablets. Additionally, in cosmetics, HPMC serves as a film-forming agent and helps improve product consistency.

MHEC is a water-soluble cellulose ether, characterized by its ability to form gels and thick solutions when mixed with water. This property makes it particularly useful in construction applications, where it acts as a thickening agent in mortars and adhesives. In the pharmaceutical industry, MHEC is used as a binder in tablets and as a coating agent for controlled release formulations. The food industry also employs MHEC as a food additive for its thickening and stabilizing properties.

3. Cosmetics and Personal Care HPMC is a common ingredient in cosmetics, offering thickening, stabilizing, and film-forming properties. Products like shampoos, conditioners, and facial creams often contain HPMC to enhance texture and performance.

Using Dow’s Hydroxyethyl Cellulose provides numerous advantages. The company has established a reputation for high-quality products that meet strict regulatory standards. Their HEC formulations are consistently reliable, ensuring that manufacturers can depend on them for their critical applications.

- Food Industry HPMC is included in various food products as a thickener, emulsifier, or stabilizer. Low viscosity grades are often used in sauces and dressings, while higher viscosities are applied in dairy products to enhance texture.

In conclusion, high viscosity HPMC is a versatile polymer with a wide range of applications owing to its thickening and stabilizing properties. Its role in pharmaceuticals, food, cosmetics, and construction underscores its importance in creating safe, effective, and high-quality products. As industries continue to seek innovative solutions that enhance performance and sustainability, high viscosity HPMC is well-positioned to meet the evolving demands of consumers and manufacturers alike. Its ability to improve the texture, stability, and efficacy of formulations makes it an invaluable asset in modern product development.

Tile Adhesives: RDP improves the adhesion, flexibility and water resistance of tile adhesives, ensuring a long-lasting installation.

Food industry applications also highlight the differences between the two cellulose ethers. HPMC is commonly used as a thickener, emulsifier, and stabilizer in various food products, including sauces, dressings, and ice creams, where it helps maintain texture and prevents separation. HEC, conversely, is more often incorporated into products where low viscosity is desired, such as in salad dressings or beverages.

China has established a robust supply chain for MHEC, driven by a well-developed chemical industry and a growing number of manufacturers that specialize in cellulose derivatives

. The country benefits from abundant natural resources, skilled labor, and a competitive manufacturing environment, allowing it to produce high-quality MHEC at diverse specifications to meet global demand.- Quality of HPMC Not all HPMC products are created equal. It’s important to choose high-quality HPMC that meets industry standards to ensure consistent performance in mortar applications.

Furthermore, HPMC is employed in personal care products, such as cosmetics and skincare formulations, where it serves as a stabilizer and thickening agent. Its non-toxic and biodegradable nature makes it an appealing option for environmentally conscious products.

- Pharmaceutical Growth With an expanding pharmaceutical industry and increasing research activities, the demand for excipients like HPMC continues to rise. The COVID-19 pandemic has also intensified the need for efficient drug delivery systems, favoring HPMC usage.

In conclusion, the pricing of HPMC powder is a complex interplay of various factors ranging from raw material costs and production capacity to market demand and geopolitical influences. Stakeholders must remain vigilant, adapting to these changes to navigate the evolving landscape of HPMC pricing effectively. As industries continue to evolve, so too will the strategies for sourcing and pricing this crucial material.

5. Fire-Fighting Measures An important aspect of the SDS, this section details the fire hazards associated with HPMC and suitable extinguishing media, helping staff to prepare for potential fire-related incidents.

Conclusion

The Role of HPMC Suppliers

Understanding the Glass Transition Temperature in HPMC

1. Pharmaceutical Industry In pharmaceuticals, HPMC is extensively used as a binder in tablet formulations, a coating agent for controlled-release formulations, and as a thickener in topical preparations. For instance, an HPMC grade with higher viscosity is preferred for creating sustained-release tablets, while lower viscosity types might be suitable for immediate-release formulations.

1. Cosmetics and Personal Care HEC is commonly used in the cosmetic industry as a thickener and stabilizer in products such as shampoos, conditioners, lotions, and creams. Its ability to provide a smooth texture and enhance the spreadability of formulations makes it a popular choice among cosmetic formulators.

2. Versatility The ability to modify properties allows for customization based on specific application needs, making it suitable for a wide range of building materials.

2. Hazard Identification HPMC is generally considered non-toxic and safe in appropriate concentrations. However, the SDS outlines any potential environmental or health risks, such as irritation to the eyes or skin upon direct contact. Understanding these risks is crucial for ensuring workplace safety.

4. Construction The construction industry leverages the properties of HPMC in cement-based products, such as tile adhesives and dry-mix mortars. Its water-retention capabilities help prevent rapid drying of mixtures, enhancing workability and improving adhesion to surfaces.

- Dosage The quantity of HPMC used must be optimized to achieve the desired effects without compromising other properties of the mortar. Typically, HPMC is used at concentrations ranging from 0.5% to 2.0% of the total weight of dry mix, but specific requirements may vary.

RDP

1. Preparing Alkaline Slurry The purified cellulose is first suspended in an alkaline solution, usually sodium hydroxide (NaOH). This treatment swells the cellulose fibers and makes them more reactive. The degree of alkalinity is critical, as it influences the efficiency of etherification.

how is hydroxyethyl cellulose made

Food Industry

Key Benefits of RDPs

The Versatile Uses of Redispersible Powder

Hydroxyethyl Cellulose for Sale A Versatile Polymer with Multiple Applications

Solubility of HPMC in Cold Water

As a company specialized in the chemical technology production for more than 15 years , our business scope is very broad .We have hydroxyethyl cellulose, hydroxypropyl methyl cellulose , redispersible powder , mortar bonding agent and tile bonding cellulose .About the hydroxyethyl cellulose , we have high quality hydroxyethyl cellulose .The hydroxyethyl cellulose price in our company are reasonable . If you are interesting in our product welcome to contact us!

Hydroxypropyl Methylcellulose (HPMC) is a versatile compound that plays a crucial role in various industries, including pharmaceuticals, food, cosmetics, and construction. HPMC suppliers are essential players in the supply chain, providing this valuable polymer that serves multiple functions, from acting as a thickening agent to enhancing the stability and performance of products. In this article, we will explore the significance of HPMC suppliers, the characteristics of HPMC, and its applications across different sectors.

4. Thickening and Gelling HPMC exhibits excellent thickening and gelling properties, which are essential in formulating creams, gels, and emulsions in the cosmetic and pharmaceutical industries.

Conclusion

In the world of construction, the integrity and durability of structures are paramount. One essential yet often overlooked component in masonry and concrete applications is the mortar bonding agent. These agents play a critical role in ensuring that mortar adheres effectively to various substrates, enhancing the overall strength and longevity of masonry work.

Hydroxypropyl Methylcellulose is a multifunctional ingredient with widespread applications across various industries. Its ability to improve texture and stability in food products, enhance drug effectiveness in pharmaceuticals, contribute to the sensory attributes of cosmetics, and optimize performance in construction materials underscores its versatility. As industries continue to prioritize sustainability and health, HPMC is poised to remain a prominent choice for manufacturers seeking reliable and effective solutions. The ongoing research and innovation surrounding HPMC also suggest that new applications may emerge, further solidifying its role in various markets. Overall, HPMC exemplifies how a single compound can significantly impact multiple fields, making it a cornerstone ingredient in today's diverse industrial landscape.

4. Reduced Shrinkage and Cracking Using cement adhesive additives can help minimize shrinkage and cracking during the curing process. This characteristic is vital in preventing structural damage and ensuring long-term stability for various construction applications.

cement adhesive additive

Pharmaceutical Applications

The first step in preparing an HPMC solution is selecting the appropriate grade of HPMC. Different grades vary in their viscosity, degree of substitution, and solubility in water, which directly impact the properties of the prepared solution. HPMC comes in various forms, including HPMC K (high viscosity), HPMC E (medium viscosity), and HPMC M (low viscosity). The choice of grade will depend on the intended application, as different viscosities provide distinct functional characteristics.

The cosmetic industry has embraced HPMC due to its thickening and stabilizing properties. It is commonly found in lotions, creams, and gels, where it helps to improve texture and enhance the sensory experience of products. HPMC also acts as a film-forming agent, contributing to the longevity of makeup and skincare formulations.

Hydroxypropyl methylcellulose (HPMC) is a non-ionic, water-soluble polymer derived from cellulose, which is primarily obtained from plant fibers. HPMC is widely recognized for its diverse applications across various industries, including pharmaceuticals, food, cosmetics, and construction. This article explores the multifaceted uses of HPMC and its significance in these sectors.

2. Filler Additives These are materials that improve the density and workability of cement mixtures. They can also enhance the adhesive properties by filling voids within the mix, thereby providing a more solid structure once cured.

cement adhesive additive

Hydroxypropyl Methyl Cellulose (HPMC) is a versatile and widely used cellulose ether that has found its way into various industries due to its impressive properties and functionalities. It is primarily derived from natural cellulose, a biodegradable polymer sourced from plant cell walls, and is modified through chemical processes to enhance its properties. HPMC has numerous applications, particularly in the pharmaceutical, food, and construction industries, making it an essential material in many commercial products.

The Role of HPMC in Different Industries

Conclusion

One of the key features of HPMC is its ability to form gels when mixed with water, which is particularly useful in various applications. Its properties can be tailored by altering the degree of substitution of hydroxypropyl and methyl groups, thus affecting both its solubility and viscosity.