harp wire screens

Latest articles

harp wire screens

...

harp wire screens 【harp wire screens】

Read Moreharp wire screens

...

harp wire screens 【harp wire screens】

Read More

harp wire screens

Post time: 11-10-22...

harp wire screens 【harp wire screens】

Read More

harp wire screensTitanium and titanium alloy with light weight, high strength, corrosion resistance and many other characteristics, titanium and its alloy not only in aviation, aerospace industry has a very important application, and has begun to chemical, petroleum, light industry, power generation, metallurgy and many other civil industrial sectors are widely used. However, titanium and titanium alloy are smaller than steel in terms of hardness and strength. The shortcomings of titanium alloy wire made of titanium alloy in terms of hardness limit its breadth and depth of application.

...

harp wire screens 【harp wire screens】

Read Moreharp wire screens

...

harp wire screens 【harp wire screens】

Read MoreWire diameter: 0.6 (mm)

harp wire screens...

harp wire screens 【harp wire screens】

Read Moreharp wire screens

...

harp wire screens 【harp wire screens】

Read MoreThe surface of the galvanized wire deposition layer before galvanized to remove the surface film layer, surface inclusion and other defects to the local, can be found and treated by conventional technology. Excess foam is caused by soaps and saponable fatty surfactants being brought into the tank. Moderate foam formation rates may be harmless.

harp wire screens...

harp wire screens 【harp wire screens】

Read More5, according to the thickness of the wire diameter to adjust zinc dipping time

harp wire screens...

harp wire screens 【harp wire screens】

Read Moreharp wire screens

...

harp wire screens 【harp wire screens】

Read More

Popular articles

There are still some differences between the welding mesh and the wire mesh and the steel mesh. This mesh is mainly a welding mesh made of high quality low carbon steel wire straightened and cut, and then welded with electric welding equipment. It can be said that because of the characteristics of fast production and convenient transportation, it has been applied to many industries. The application of welding mesh in the industry, because the mesh has strong corrosion resistance and uniform mesh. It has become a special grid for floor heating in the building industry and has been applied in many fields.

- Hook net raw materials are basically low carbon steel wire, stainless steel wire and aluminum alloy silk woven, and what are the characteristics and use of these raw materials? Low carbon steel wire is actually the wire we usually use, plasticity is good, good patience, pull is very good.

Latest articles

-

-

Post time: 04-04-23 -

-

-

The common type of barbed rope is double-strand barbed rope, and the models are 2.0*2.0mm, 2.25*2.25mm, 2.7*2.25mm, and all of them are galvanized barbed rope (plastic coated barbed rope is rarely used). The barbed distance (that is, the distance between winding wires) is generally 14 cm. Here’s what these models mean:

-

Links

- Heavy duty sewing needles, as the name suggests, are built for intense and resilient sewing tasks. They are made from high-grade steel, making them stronger and more resistant to bending or breaking under pressure. This robust construction allows them to easily pierce through denim, canvas, leather, upholstery, and other heavy fabrics without damaging the material or the machine.

In conclusion, bag closing machinery is an indispensable component in the packaging landscape, delivering the necessary security and efficiency needed in today’s competitive market. With a variety of options available, businesses must carefully assess their specific needs to choose the right machinery. By doing so, they can ensure that their products are packed securely and efficiently, ultimately leading to improved customer satisfaction and increased profitability. As technology continues to advance, we can expect further innovations in bag closing solutions that will enhance productivity and streamline operations for businesses worldwide.

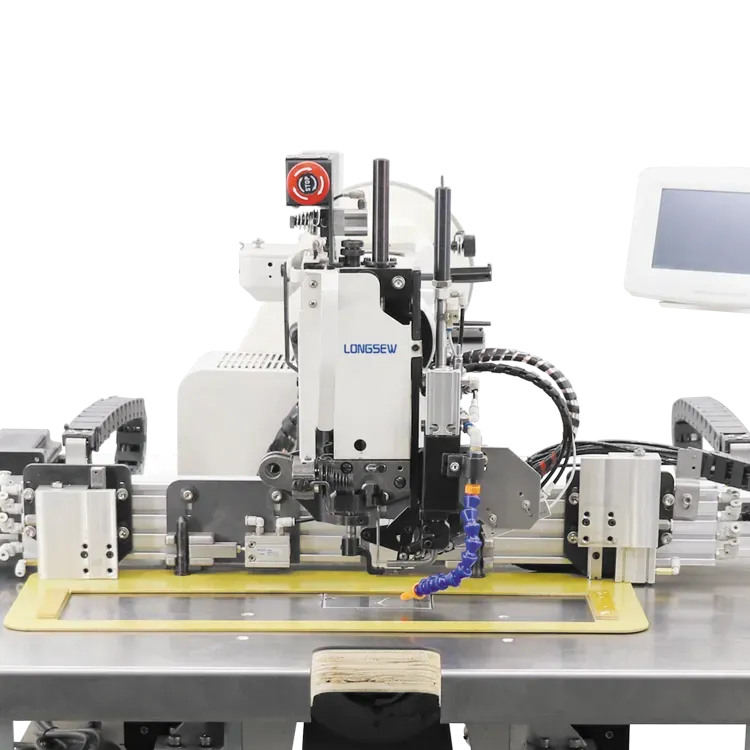

A two needle embroidery machine is an advanced piece of equipment that allows users to utilize two needles simultaneously. This dual-needle setup enables the machine to use two different colors of thread or types of stitches at once, thereby saving time and improving productivity. These machines are often equipped with sophisticated software that allows for intricate designs and patterns to be created with ease.

A double needle sewing machine is a specialized sewing machine that uses two needles and two threads simultaneously to create parallel rows of stitching. It is equipped with a unique needle holder that holds both needles side by side, allowing for specific stitching techniques that single-needle machines cannot achieve. This machine can create various stitch types, including straight stitches, decorative stitches, and cover stitches, making it versatile for different sewing projects.

Automotive sewing machines are designed specifically for the demands of the automotive industry. They are typically constructed to handle thick and layered materials like leather, synthetic fabrics, and foam, which are commonly used in car interiors. These machines often come with specialized attachments and stitching patterns that cater to a wide variety of tasks, from sewing intricate seat designs to creating durable door panels.

automotive sewing machine

Another crucial aspect of bulk bag sewing machines is the precision they offer. Consistent stitching is vital in ensuring the integrity and strength of the bags, especially when they are filled with heavy materials. High-quality sewing machines come equipped with advanced technology that enhances stitch quality and uniformity. This precision helps to prevent leaks and failures, which can have dire consequences in industries handling hazardous materials.

For those who fear that sewing machines can be intimidating, the New Home Super Automatic Sewing Machine is designed with user friendliness in mind. It features an intuitive interface, often with an LCD screen that guides users through selecting stitches and settings. Many models also come with automatic needle threading capabilities, eliminating one of the more frustrating tasks often associated with sewing.

In today's fast-paced world, efficiency and precision play a pivotal role in the textile and fashion industries. One of the key players in enhancing these aspects is the auto sewing machine. As technology advances, the pricing of auto sewing machines has become an important subject for both manufacturers and consumers. Understanding the factors influencing their prices can help businesses and individual sewists make informed decisions.

4. Precision The mechanism of interlocking threads ensures clean, precise stitches that enhance the overall quality of the finished product.

Operation

Heavy-duty sewing machines are engineered to sew through thick materials such as stubborn leather, heavy webbing, denim, and upholstery. Heavy-duty machines can be used both in a home environment and as industrial sewing machines in a commercial setting. The information will help you find the best sound-quality sewing machine for your individual needs.

Workspace Requirements

The Evolution and Impact of Automatic Computerized Sewing Machines

Finding the Right Machine for You

Moreover, the integration of technology into these machines often includes features like computerized stitching, real-time monitoring, and customizable settings. Users can adjust parameters such as stitch length and width, and some machines even come with Wi-Fi connectivity that allows for software updates and pattern downloads directly from online resources. This level of customization ensures that users can adapt to various projects and materials, promoting creativity and innovation in design.

Moreover, weather resistance is paramount in tent making. The stitching must be strong and secure to prevent leaks during rainy days. Consequently, the sewing machine should have options for various types of stitches, including straight, zigzag, and reinforced stitching.

Heavy Duty Thread for Sewing Canvas A Comprehensive Guide

Conclusion

At its core, double needle sewing requires an understanding of how to set up a sewing machine correctly. Most domestic sewing machines can be adapted for this technique by simply replacing the single needle with a double needle, typically ranging from 1.6mm to 4.0mm apart. The two needles are inserted into the machine just like a standard needle, but they must be used with a zigzag stitch or a straight stitch that allows for the dual-thread functionality. Additionally, it's crucial to use the correct type of thread and needle for the fabric being sewn, ensuring that the result is both visually appealing and structurally sound.

Heavy-duty and industrial sewing machines serve distinct needs, with the former bridging the gap between household and professional machines. While industrial units excel in continuous, specialized tasks, heavy-duty machines can effectively sew light fabrics when tailored with appropriate settings, such as stitch length, tension control, and needle choices. However, challenges like machine speed, feed dogs, and thread choice need careful management. Regular maintenance and choosing versatile machines, backed by expert advice and reviews, can ensure optimum results across various fabrics, from robust denim to delicate silks.

Sewing Thick Fabrics with a Walking Foot Sewing Machine

However, there are some considerations to keep in mind when using a twin needle sewing machine. First, it is essential to select the right needle size—the size of the needle will depend on the thickness and type of fabric being used. Additionally, it is crucial to utilize threads that can accommodate the dual stitching process; using the wrong type of thread can lead to breakage or uneven stitching. Lastly, adjusting the machine's tension settings may be necessary based on the fabric and thread selections to ensure a cohesive finish.

In terms of ergonomics, cylindrical bed sewing machines also promote a more comfortable working environment. The design of the machine allows for better visibility of the sewing area and reduces the need for awkward hand movements. This aspect is particularly important in high-paced production settings, where operator fatigue can become a significant factor affecting overall productivity and quality.

In conclusion, sewing with heavy canvas offers endless possibilities for both functional and creative projects. With the right tools and techniques, anyone can learn to master this versatile fabric. Whether you’re crafting bags, outdoor gear, or home décor, the sturdy nature of heavy canvas makes it a fantastic choice for those looking to create lasting and practical items. So grab your sewing machine, some heavy canvas, and let your creativity flow—there’s a world of projects waiting to be stitched!

Leather hand stitching is an ancient craft that marries functionality with artistry, creating unique and durable items that stand the test of time. From wallets and belts to bags and shoes, hand-stitched leather goods are celebrated for their beauty and craftsmanship, offering a personal touch that machine-made products often lack.

1. Heavy-Duty Construction Upholstery fabrics are often thick and robust, such as canvas, denim, or leather. Seeking a sewing machine made with durable materials will ensure it can handle the stress of heavy fabrics without breaking or malfunctioning.