cost of welded wire fabric

Latest articles

cost of welded wire fabric

...

cost of welded wire fabric 【cost of welded wire fabric】

Read More

cost of welded wire fabricCompared with other galvanizing processes, the cleaning requirements for low carbon steel wire before galvanizing are low. However, under the current trend of increasing the quality level of galvanized layer, some pollutants brought into the plating tank are obviously harmful. Because cleaning galvanized coating wastes a lot of time and reduces the production, it is very important to properly clean and effectively rinse the substrate before electroplating.

...

cost of welded wire fabric 【cost of welded wire fabric】

Read Morecost of welded wire fabric

...

cost of welded wire fabric 【cost of welded wire fabric】

Read More

cost of welded wire fabricAfter annealing, the wire will become soft, flexibility will increase, iron is a relatively active metal, and more active than hydrogen, so it is a good reducing agent. At room temperature, iron is not easy to react with oxygen, sulfur, chlorine and other non-metallic elements in dry air. Its production cost is lower, its use and scale are also relatively wide, and it has better protective function. Therefore, it is an important material for steel parts in strict working environment.

...

cost of welded wire fabric 【cost of welded wire fabric】

Read Morecost of welded wire fabric

...

cost of welded wire fabric 【cost of welded wire fabric】

Read More

cost of welded wire fabricThe diameter of cold-drawn wire should conform to the contract, check whether the amount of zinc meets the requirements of the contract, check the tensile strength, and ask the factory to provide the corresponding inspection report. The wire factory introduces that the weight of a single coil of wire of different specifications should not be lower than the volume weight required by the contract, and record the value. No contacts are generated for each reel of wire. If there are contacts, no more than three contacts are generated for each reel. Each contact should be smooth surface treatment, the wire can not be pulled off from the contact, in line with customer packaging requirements.

...

cost of welded wire fabric 【cost of welded wire fabric】

Read Morecost of welded wire fabric

...

cost of welded wire fabric 【cost of welded wire fabric】

Read Morecost of welded wire fabric

...

cost of welded wire fabric 【cost of welded wire fabric】

Read More

cost of welded wire fabricFor mountainous or hilly areas where the ground is more undulating set up stakes. You need to set a stake at the beginning and the end, and then determine the position. In the middle of the ups and downs, to increase the stakes according to the complexity of the ups and downs of the terrain, we need to be able to see 3 stakes at the same time, so that the installation is. It’s a straight line.

...

cost of welded wire fabric 【cost of welded wire fabric】

Read Morecost of welded wire fabric

...

cost of welded wire fabric 【cost of welded wire fabric】

Read More

Popular articles

The distance between the adjacent two thorn rope installation do not know whether you have noticed? Careful observation can find that its spacing is not the same, the thorn rope factory for customer consultation when asking the installation height of the reason.

Benefits of using a pet cage:

In the use of time do not need to carry out daily maintenance and maintenance, not only can save a lot of time, but also can reduce the cost, but also has good stability, strong corrosion resistance, greatly prolong the service life. According to the different process is divided into different kinds, can be selected according to their own needs, has good flexibility and elasticity. The main role of annealing wire is to control its degree of hardness and softness. When making annealing wire, it is made of steel wire.

Hot dip galvanizing is also called hot dip zinc and hot dip galvanizing: is an effective way of metal corrosion, mainly used in various industries of metal structure facilities. It is to immerse the steel parts after rust removal into the molten zinc liquid at about 500℃, so that the surface of the steel parts is attached with zinc layer, so as to play the purpose of anticorrosion. Hot dip galvanizing process: finished product pickling – washing – adding bath aid – drying – hanging plating – cooling – drug – cleaning – grinding – hot dip galvanizing completion. Hot dip galvanizing is developed from the older method of hot dip galvanizing. It has a history of 140 years since it was applied to industry in France in 1836. However, the hot dip galvanizing industry has been developed on a large scale in the past 30 years with the rapid development of hot dip galvanizing wire.

Latest articles

-

Generally speaking, there are three kinds of anti-corrosion and anti-rust skills: surface dipping, spraying and surface galvanized, these three ways are to strengthen their anticorrosion ability and resist natural risks, extend their service life. Today we want to talk about the difference between dip plastic hook and galvanized hook.

-

Galvanized wire drawing is more common in our life, galvanized wire drawing refers to the production of galvanized iron wire after a series of processes such as shell stripping. The production process of galvanized wire drawing is more complex, and a series of problems may occur if there is a slight mistake. When the wire factory is engaged in the production of galvanized wire drawing, it is necessary to remove all the tools and piles that hinder activities on the work site and equipment.

-

Some customers do not understand the range of application of different styles of barbed rope, so there is a big difference.

-

The use of packaging galvanized wire with the development of industry and agriculture is also expanded accordingly. Therefore, galvanized silk commodities have been widely used in industry (such as chemical equipment, petroleum processing, Marine exploration, metal structure, electric power transportation, shipbuilding, etc.), agriculture (such as irrigation, heating houses), construction (such as water and gas transportation, wire casing, scaffolding, houses, etc.), Bridges, transportation, etc., in recent years. Because galvanized silk products have beautiful surface, good corrosion resistance and other characteristics, its use is more and more extensive.

-

Open pit coal mine due to poor air quality, a variety of harmful heavy metals are also more, so the corrosion strength of barbed rope products is particularly large, when using galvanized barbed rope must choose hot plating or plastic coated galvanized barbed rope, although the price is slightly higher, but in the long term development is more appropriate. Besides, when the barbed rope is installed near the coal mine, the pile foundation should be fixed to prevent the barbed rope from falling down due to soil erosion, thus losing the protective effect.

-

Packing and binding galvanized wire is in the liquid state of zinc, after a messy physical and chemical effect, not only on the steel plated thick pure zinc layer, and also generate a zinc-iron alloy layer. This kind of plating method, not only has the corrosion characteristics of the electric galvanized wire, and because of a zinc alloy layer. It also has strong corrosion resistance that can not be compared with electric galvanizing. Therefore, this plating method is particularly suitable for a variety of strong acid, alkali fog and other strong corrosive environment.

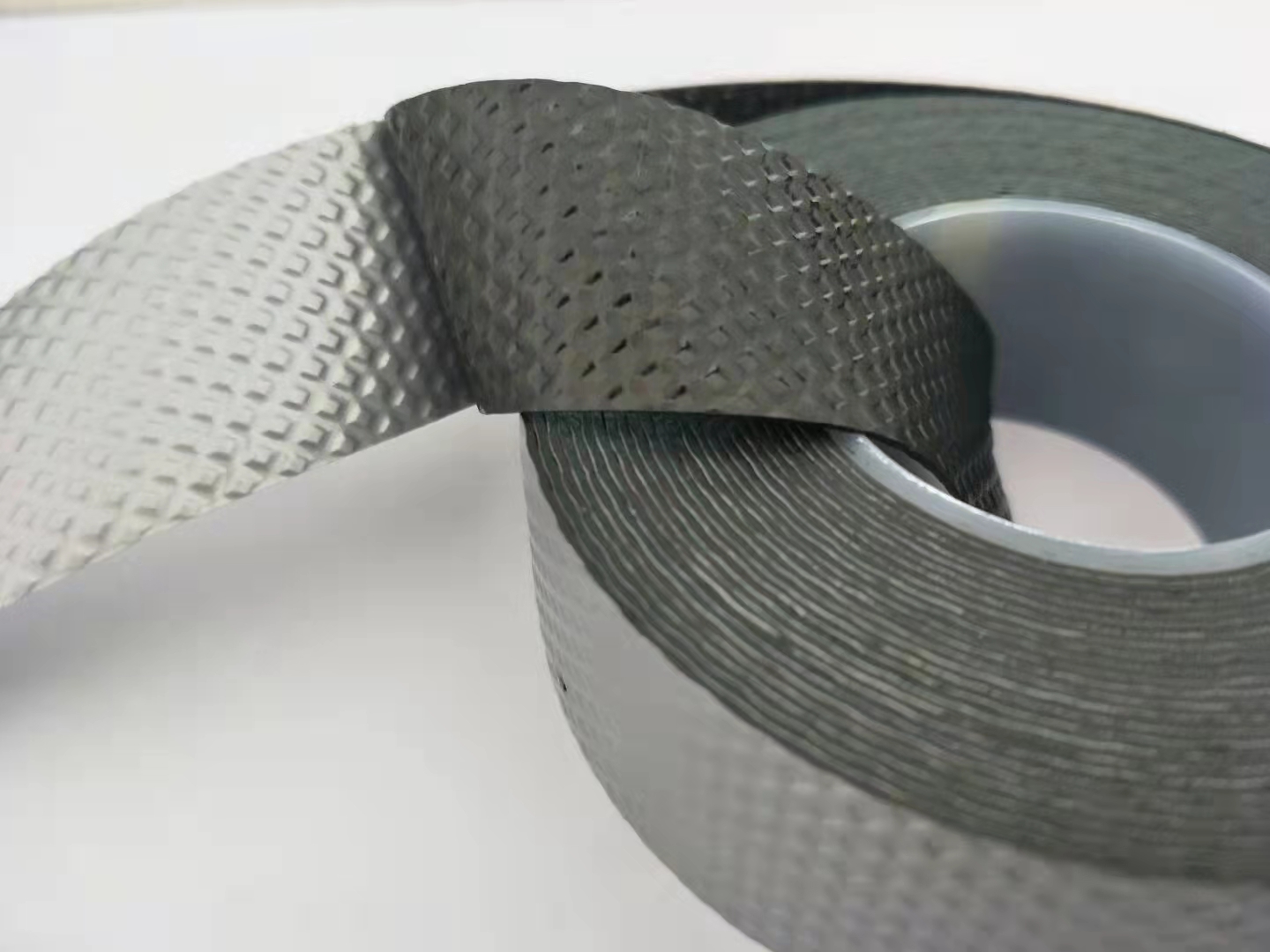

Self-bonding helps makes an air and watertight seal.

Key Features and Benefits

pvc electrical tape suppliers. Look for suppliers that have a history of providing high-quality products and excellent customer service. You can also check online reviews and testimonials to get an idea of the supplier's reputation.

Easy Application The tape is easy to apply, requiring no special tools or equipment, making it a convenient solution for a variety of applications Easy Application The tape is easy to apply, requiring no special tools or equipment, making it a convenient solution for a variety of applications

Easy Application The tape is easy to apply, requiring no special tools or equipment, making it a convenient solution for a variety of applications Easy Application The tape is easy to apply, requiring no special tools or equipment, making it a convenient solution for a variety of applications 3m self vulcanizing tape.

3m self vulcanizing tape.Creates a strong, seamless, waterproof and electrically insulating layer.

safety floor tape. In high-risk areas where special precautions are necessary, safety floor tape can be used to clearly mark off these areas and prevent unauthorized access.

Easy Application The tape is easy to apply, requiring no special tools or equipment, making it a convenient solution for a variety of applications Easy Application The tape is easy to apply, requiring no special tools or equipment, making it a convenient solution for a variety of applications

Easy Application The tape is easy to apply, requiring no special tools or equipment, making it a convenient solution for a variety of applications Easy Application The tape is easy to apply, requiring no special tools or equipment, making it a convenient solution for a variety of applications 3m self vulcanizing tape.

3m self vulcanizing tape.The interface is the display component that gives you access to your control box. It allows you to set your control box or even perform diagnostics. Typical control box interfaces come in the form of switches and boxes. However, there are advanced interfaces that include touchscreens.

What is Butyl Tape?

Composition and Features

DIY enthusiasts also find black PVC electrical tape invaluable. Whether it’s for crafting, organizing cords, or making quick repairs, this versatile tool is easily accessible and simple to use. For instance, if a power cord becomes frayed, wrapping it securely with black PVC tape can quickly restore functionality without the need for costly repairs or replacements.

Sensors

brown insulation tape. It finds its utility in automotive repairs, plumbing, HVAC systems, and even in sports and fitness for securing athletic gear or providing support to muscles. Its ease of use, combined with its durability, makes it a go-to solution for quick fixes and preventive maintenance tasks.

brown insulation tape. It finds its utility in automotive repairs, plumbing, HVAC systems, and even in sports and fitness for securing athletic gear or providing support to muscles. Its ease of use, combined with its durability, makes it a go-to solution for quick fixes and preventive maintenance tasks.Basics of a Control Box

Workers learned to respect the boundaries it set, recognizing that each marked path and area had its significance Workers learned to respect the boundaries it set, recognizing that each marked path and area had its significance

Workers learned to respect the boundaries it set, recognizing that each marked path and area had its significance Workers learned to respect the boundaries it set, recognizing that each marked path and area had its significance red floor tape.

red floor tape.