One of the primary benefits of cement bonding additives is their ability to improve adhesion. In various applications, such as tile setting, plastering, or repairing concrete surfaces, enhancing the bond between the cement and the underlying substrate is crucial. Bonding additives increase the cohesion and friction between particles, which helps create a more robust bond. This is especially important in areas subject to high stress or where exposure to moisture and temperature variations may occur.

cement bonding additive

6. Applications of Redispersible Polymer Powder

6. Other Applications

HPMC Powder A Versatile Polymer for Industrial Applications

Moreover, liquid thickeners are instrumental in catering to specific dietary needs, especially for individuals with swallowing difficulties, a condition known as dysphagia. Thickeners are often used in modifying the consistency of liquids to make them safer and easier to swallow. This has prompted the development of specialized thickening agents that meet various clinical guidelines, ensuring patients can consume nutritionally rich fluids without the risk of aspiration.

In summary, Hydroxypropyl Methyl Cellulose (HPMC) is a multifunctional polymer with extensive applications across several industries. Its unique properties make it an indispensable ingredient in pharmaceuticals, food products, cosmetics, and construction materials. As the demand for natural and safe additives continues to rise, HPMC stands out as a reliable choice for manufacturers seeking to enhance the efficacy and quality of their products. With its versatility and safety profile, HPMC is poised to maintain its relevance in an array of applications for years to come.

The use of redispersible polymer powders also promotes sustainability in construction. By enhancing the properties of conventional materials, RDPs allow for the use of lower quantities of cement, leading to a reduction in carbon emissions associated with cement production. Furthermore, their ability to improve the durability and lifespan of construction materials also contributes to resource conservation over time.

The construction industry has also benefited from the unique properties of HPMC. It is commonly used in the formulation of cement-based dry-mix products, such as tile adhesives and joint compounds. HPMC improves workability, water retention, and adhesion of these materials, making application easier while ensuring durability and performance. Moreover, its water-retaining properties are critical, as they allow for better curing of cement, which ultimately enhances the strength of the final structure.

hpmc hydroxypropyl methylcellulose

Depending on your sector, there are certain industry-specific platforms where Cellosize and similar products can be purchased. For example, if you're in construction, platforms catering to building materials may have HEC available as part of their inventory. In the cosmetics field, suppliers that focus on personal care ingredients may stock hydroxyethyl cellulose for formulation purposes. These specialized platforms can be a goldmine for finding not just Cellosize, but also complementary products that may be used in conjunction with it.

One of the most significant advantages of redispersible polymer powders is their capability to enhance the mechanical properties of construction materials. For instance, when integrated into cementitious systems, they can help reduce the brittleness of the materials. This results in a more flexible final product capable of absorbing stresses without cracking. Moreover, RDPs improve the thin-layer application properties of mortars and adhesives, facilitating easier application and better aesthetics.

Hydroxypropyl Methylcellulose (HPMC) is a widely used polymer, particularly in pharmaceutical, food, and cosmetic industries. One of the critical properties of HPMC is its gelation temperature, which is a crucial factor in its application and performance. Gelation temperature refers to the temperature at which a solution transforms from a sol (liquid) state to a gel (solid-like) state. This phenomenon has significant implications for formulations, product stability, and user experience.

The synthesis of HPMC typically involves three main steps cellulose preparation, etherification, and purification

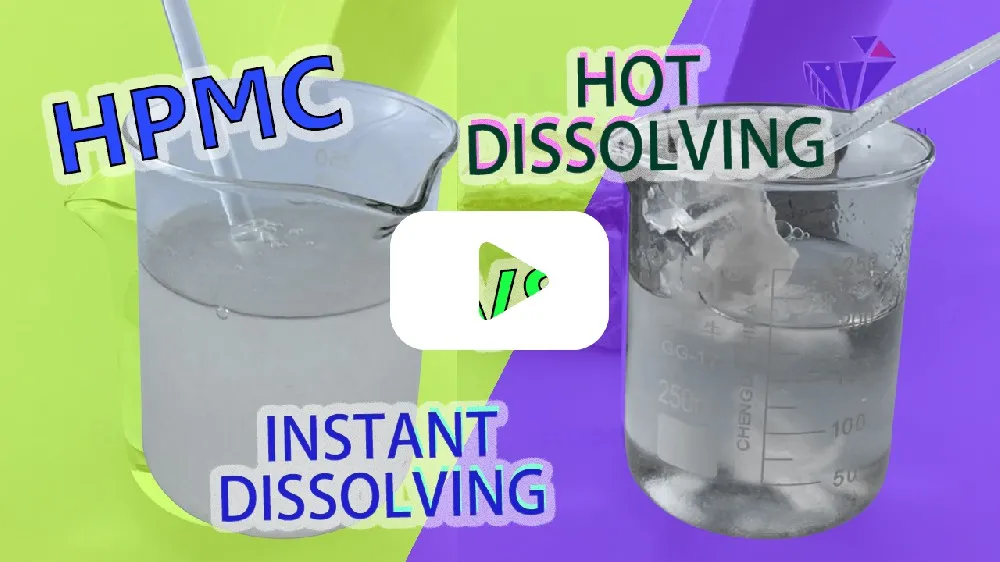

.The solubility of HPMC is a critical parameter that affects its functionality across different applications. Solubility refers to the ability of a substance to dissolve in a solvent, forming a homogeneous solution. For HPMC, its solubility in water makes it an exceptional option in industries such as pharmaceuticals, food production, cosmetics, and construction materials. In the pharmaceutical industry, for instance, HPMC is used as a binder in tablets, as it forms a gel-like matrix that ensures controlled drug release.

The pharmaceutical and cosmetic industries also recognize the value of MHEC due to its ability to form gels and stabilize emulsions. In pharmaceuticals, it serves as a binder in tablet formulations and as a thickening agent in topical preparations, ensuring that active ingredients are delivered effectively. The cosmetic sector benefits from MHEC in formulations like creams and lotions, where it aids in achieving the ideal texture and consistency, enhancing user experience.

Understanding Methyl Hydroxyethyl Cellulose Properties and Applications in China

4. Construction Grades HPMC is also used in the construction sector, where it functions as a water-retention agent in cement and gypsum-based products. It improves workability and ensures better adhesion and durability of materials.

Innovation in HPMC Production

1. Improved Workability One of the primary benefits of incorporating HPMC into gypsum plaster is the enhanced workability it provides. HPMC increases the viscosity of the plaster mixture, making it easier for workers to apply and spread the material. This is particularly beneficial for large surface areas or intricate designs, where precision is critical.

In conclusion, hydroxypropyl methylcellulose (HPMC) is a versatile compound with diverse applications across multiple industries. Its role as a pharmaceutical excipient, food additive, cosmetic ingredient, construction material additive, and support material in 3D printing showcases its significance in modern manufacturing and formulation processes. As research continues, the potential applications of HPMC may expand, further establishing its importance in various fields.

Molecular weight also plays a pivotal role in determining HPMC's solubility. Lower molecular weight HPMC is generally more soluble in organic solvents than its high molecular weight counterparts due to the reduced entanglement of polymer chains. This characteristic can be particularly important during the processing of drug formulations, where the solubility and viscosity of HPMC can significantly impact the release profile of the active pharmaceutical ingredient (API).

hpmc solubility in organic solvents

Methylcellulose (MC) is also a water-soluble polymer that is derived from cellulose. It is obtained by reacting cellulose with methyl chloride. Like HPMC, MC is used as a thickener, emulsifier, and stabilizer in various applications. However, MC is not as versatile as HPMC and is mainly used in the food industry as a food additive.