4x4 welded wire panels

Latest articles

4x4 welded wire panels1. Choose the right cage for your dog according to its size

...

4x4 welded wire panels 【4x4 welded wire panels】

Read More“Wet” hot dip galvanizing is also called “molten solvent method” hot dip galvanizing. Iron and steel workpiece through degreasing, pickling and cleaning, it is necessary to set in a special box above the surface of the molten zinc in the “molten solvent” (also called cosolvent), and then into the zinc liquid to galvanized. The molten solvent is usually a mixture of ammonium chloride and zinc chloride, but also other chlorine salts.

4x4 welded wire panels...

4x4 welded wire panels 【4x4 welded wire panels】

Read More

4x4 welded wire panels...

4x4 welded wire panels 【4x4 welded wire panels】

Read More4x4 welded wire panels

...

4x4 welded wire panels 【4x4 welded wire panels】

Read More

4x4 welded wire panels

Post time: 10-02-23...

4x4 welded wire panels 【4x4 welded wire panels】

Read More4x4 welded wire panels

...

4x4 welded wire panels 【4x4 welded wire panels】

Read More

4x4 welded wire panelsTraditional barbed wire is crisscross woven into the wire, with the development of the economy, the rapid rise of all walks of life, the limitations of the use of traditional barbed wire gradually exposed, such as: aquaculture, to the chicken circle cage can not be too dense, the wire can not be too thick, woven mesh wire once the mesh will become soft. We also have coping methods: 1, cotton gouging, rolling straight wire into wavy shape, but still not enough to raise chickens with mesh can only be extended to the beak can not feed! 2, is the electric welding net, with the current of the longitude and weft wire spot welding together, the mesh is not limited to do more.

...

4x4 welded wire panels 【4x4 welded wire panels】

Read MoreZinc-coated wire is dipped in molten zinc with high production speed and thick but uneven coating. The thickness allowed by the market is 45 microns, the color is dark, the consumption of zinc metal, and the base metal to form infiltration layer, good corrosion resistance, hot dip galvanizing can be maintained for decades in the outdoor environment.

4x4 welded wire panels...

4x4 welded wire panels 【4x4 welded wire panels】

Read More

4x4 welded wire panelsLike highway guardrail, silk screen can be used, in production can also be according to the needs of customers, such as the need for different diameters of galvanized wire products, in the material selection and coating to carry out reasonable control. Our industry is a low carbon steel with good quality as raw material, and then through the pulling out, galvanized process, thus producing good galvanized iron wire.

...

4x4 welded wire panels 【4x4 welded wire panels】

Read More4x4 welded wire panels

...

4x4 welded wire panels 【4x4 welded wire panels】

Read More

Popular articles

Through the maintenance of galvanized wire, it can not only greatly prolong its service life, but also improve its efficiency in the daily use process. Because the labeled electrode potential of zinc is -0.762v, which is negative than iron, zinc becomes the anode when the galvanic cell is formed after being corroded by the medium. It itself is dissolved to protect the steel matrix. The duration of the protection of galvanized wire layer has a great relationship with the thickness.

- 4. Choose according to habits

- 1, prepare for the bird cage

- The difference between 304 and 201 stainless steel wire rolling cage is the difference in material, material determines the price, so the price of 304 stainless steel blade gill net is slightly higher, the following mainly to explain the difference in two raw materials.

To many people, a dog cage looks like a prison, but for dogs who have been raised on cage training, it is their home and shelter. A cage should be a comfortable place. Never put a dog in a cage for no reason. They will see it as punishment. (Why do many dogs fail to adapt to their owners’ commands, because whether the paparazzi can come out or not, it is also seen as a punishment.

Latest articles

-

The production process is to roll the hot metal billet into 5mm thick steel, and then put it into the wire drawing device, draw into different diameters of the line and gradually reduce the aperture of the wire drawing disk. Production process through cooling, annealing, coating and other processing technology, and then made into a variety of different specifications of galvanized wire. Galvanized wire production because of simple process, wide application, early development. Galvanized wire or steel wire is a cold working product of steel wire, and the material used is generally low carbon steel or stainless steel.

-

Because of its light weight, strength is relatively large has gradually begun to replace the original column. At the same time, due to the relatively uniform specifications, the barbed rope installation is also more beautiful. The direct spacing of the barbed rope is relatively fixed, which can effectively prevent crossing. At the same time, the mesh at the bottom is relatively dense, while the mesh at the top is relatively loose, which can save resources.

-

Wire mesh welding after galvanized is through the end of the welding and then the cold company to make wire mesh wire mesh steel mesh construction mesh floor heating mesh galvanized or hot galvanized. After the first galvanized welding is to change the wire mesh, after the end of welding can see the welding spot; The two processes are different prices are also very different, the cost of the first plating after welding is low, the appearance is smooth, and the cost of the first welding after plating is higher, not easy to rust.

-

-

-

Links

When it comes to ceiling access panels for drywall, design is essential. These panels are typically lightweight and made of materials that blend seamlessly with existing drywall ceilings. They come in various sizes and styles to accommodate different applications, from small panels for electrical access to larger ones for comprehensive inspections of HVAC units.

Installing an access panel in a drywall ceiling is a straightforward task that can enhance the convenience of your home. By following these steps, you can create an easy entry point for repairs and maintenance, ensuring that both you and your home benefit from this installation. Remember to always exercise caution when working with drywall and electrical or plumbing systems, and don’t hesitate to consult a professional if you are unsure about any aspect of the installation. With the right approach, you’ll have a properly functioning access panel in no time!

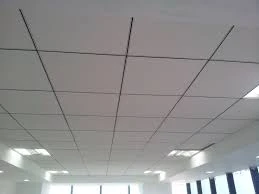

The cross T ceiling grid embodies a perfect blend of functionality and design appeal, making it an invaluable choice for architects and interior designers. Its modular characteristic, combined with benefits such as acoustic control, easy installation, and accessibility, positions it as a go-to solution for a wide range of applications. As design trends continue to evolve, the cross T ceiling grid will undoubtedly remain a staple in creating efficient, modern, and aesthetically pleasing spaces. Whether in commercial real estate or residential projects, understanding the value and application of this ceiling system can significantly enhance the overall design and functionality of any environment.

3. Adding Cross Tees Insert the cross tees between the main runners according to the planned layout. Ensure that the grid is squared, with consistent spacing.

Understanding Laminated Gypsum Board Benefits and Applications

Durability is a hallmark of fiber tiles. Unlike traditional tiles that can crack or chip, fiber tiles are highly resilient and can endure heavy foot traffic, making them suitable for both residential and commercial spaces. They are also resistant to moisture and stains, especially when treated with protective coatings, making maintenance straightforward. Regular vacuuming and occasional cleaning with a damp cloth can keep them looking fresh and appealing over time.

Conclusion

- Commercial Buildings In offices, retail spaces, and warehouses, these panels allow for easy access to ventilation systems, electrical conduits, and plumbing, facilitating routine maintenance.

Ultimately, choosing between gypsum board and PVC ceiling depends on the specific needs of the space in question. For areas that require fire resistance and superior sound insulation, gypsum board may be the ideal choice. In contrast, for spaces that are prone to moisture and require a low-maintenance solution, PVC ceilings could be more appropriate.

4. Plastic Access Panels Lightweight and easy to install, plastic access panels are often used in residential applications where the aesthetic is paramount. They are also resistant to moisture, making them suitable for bathrooms or kitchens.

PVC Grid False Ceilings Transforming Spaces with Decorative Versatility

Mineral fiber ceilings present a viable choice for those looking for cost-effective, functional, and aesthetically pleasing ceiling solutions. With their superior sound absorption, ease of installation, and maintenance, they cater to a variety of needs in both commercial and residential spaces. As sustainability continues to gain importance in construction, the environmentally-friendly properties of mineral fiber ceilings make them an even more appealing option for modern interiors. Whether renovating an old space or designing a new one, considering mineral fiber ceilings can aid in achieving a harmonious blend of style and utility.

5. Maintaining Access and Functionality Access panels are essential for providing necessary access to concealed systems for maintenance or inspection. Plastic panels can facilitate easy access without disrupting the overall design of a space, ensuring that any required repairs can be conducted quickly.

- - Paint (optional, for finishing touches)

Historically, ceiling trap doors were integral to the design of many homes and public buildings. They allowed for the efficient use of vertical space, providing access to attics, lofts, or storage areas that might otherwise remain unused. In ancient times, these trap doors often served practical purposes, such as allowing tradespeople to deliver goods or supplies without infringing upon the space within the main living area. In some grand estates, they were cleverly designed to facilitate the movement of household staff or to conceal valuables.

Ceiling access panels are designed to provide direct access to the areas above ceilings that might otherwise be difficult to reach without dismantling drywall. This feature is especially important in the case of ongoing maintenance and repairs. For example, if a plumbing issue arises or if electrical work is required, an access panel can save considerable time and effort by allowing easy entry without the need for extensive renovations.

2. Quality and Compliance Look for suppliers who provide items that meet local building regulations and safety standards. Quality certifications can be a good indicator of a supplier's commitment to delivering reliable products.

- 3. Environmental Concerns PVC production can release harmful chemicals, and while some panels are recyclable, not all PVC products are eco-friendly.

5. Accessibility With their defined access points, Gyptone panels allow for quick and efficient access to necessary utilities, such as electrical wiring, plumbing, and HVAC systems. This is especially valuable during maintenance or renovations, reducing downtime and labor costs.

- Educational Institutions Schools and universities require access to ceiling systems for maintenance and safety inspections. Flush access panels are ideal for classrooms and lecture halls where a tidy appearance is crucial.

The T Runner Ceiling Understanding Performance Limitations in Sprinting

4. Synthetic Resins Depending on the manufacturer, various synthetic resins may be added to bind the fibers together and improve the overall durability of the tiles. These resins also help to control moisture, reducing the likelihood of mold and mildew growth, which can be a concern in humid environments.

One of the standout features of mineral fiber ceiling boards is their ability to absorb sound. The Noise Reduction Coefficient (NRC) rating is a key specification to consider when evaluating acoustical performance. The NRC values can range from 0.00 to 1.00, with higher values indicating better sound absorption. Typically, an NRC of 0.70 or above is desirable in commercial spaces such as offices, schools, and conference rooms. This characteristic not only helps to reduce noise within a space but also enhances overall comfort for occupants.

The production of mineral fiber board begins with the selection of raw materials, such as basalt or recycled glass. These materials are melted in a furnace at temperatures exceeding 1,400 degrees Celsius. Once melted, the molten material is extruded and spun into fine fibers, which are then collected and laid down in mats. The mats are compressed and treated with various additives to enhance their properties, such as fire resistance, thermal insulation, and moisture repellency. Finally, the mats are cured and cut into boards of various dimensions for use in construction.

Cut the tiles as needed to fit around obstructions such as lights, vents, or pipes. Use a sharp utility knife or tile cutter to make precise cuts.

In summary, suspended ceiling tees are an integral part of contemporary building designs, offering versatility, aesthetic enhancement, and practical benefits for a variety of applications. Their ability to conceal utilities, improve acoustics, and contribute to fire safety makes them essential in many commercial and residential projects. As design trends evolve, suspended ceiling systems will continue to play a vital role in shaping the interior environments we inhabit. Whether in a bustling office or a serene classroom, the impact of suspended ceiling tees is both significant and lasting.

Applications Across Industries

Step-by-Step Guide

Understanding the Price of Mineral Fiber Ceiling Boards

Mineral fiber ceiling boards are manufactured using a blend of natural minerals, such as gypsum, and synthetic fibers. The specifications of these ceiling tiles can vary, but they typically include the following key features

The primary reason for including access panels in drop ceilings is convenience. They provide quick and efficient access to above-ceiling infrastructure, which is particularly important for commercial and institutional buildings where routine maintenance is a necessity. Without access panels, maintenance personnel would have to remove entire ceiling tiles or panels, leading to additional labor costs and potential damage to the ceiling structure.

- Efficiency Easily accessible areas reduce the time needed for maintenance tasks. A correctly sized access panel enables technicians to perform their jobs more efficiently, ultimately saving time and money.

- Partitions Its lightweight properties make it suitable for creating internal partitions that are both functional and aesthetic.

PVC laminated ceilings require minimal maintenance compared to other ceiling types. They do not require painting, polishing, or special cleaning agents; a simple wipe with a damp cloth is often sufficient to keep them looking new. Additionally, they are resistant to mold and mildew, which can be a significant concern in humid environments. This ease of maintenance not only saves time and effort but also reduces long-term costs, as less upkeep is required.

pvc laminated ceiling

3. Installing Main Tees Main tees are then hung from the structural ceiling using hangers, ensuring that they are level and properly spaced according to the design.

From an aesthetic perspective, the size and design of access panels should complement the overall ceiling design. Access panels are often available in a variety of styles, including flush-mounted options that blend seamlessly into the ceiling. This is particularly important in spaces where décor and design are prioritized, such as in residential environments or high-end commercial settings. A well-chosen access panel can maintain the clean lines and visual appeal of a ceiling while providing necessary functionality.

What is a Ceiling Grid?

Conclusion

Installation Considerations

4. Easy Maintenance Cleaning and maintaining PVC gypsum panels is straightforward. They can be easily wiped down to remove dirt and stains, making them a practical choice for high-traffic areas.

In terms of aesthetics, gypsum ceilings offer versatility in design. They can be painted or finished with a variety of textures, creating different visual effects suited to diverse architectural styles. Gypsum ceilings also allow for intricate designs, such as gypsum moldings or false ceilings with recessed lighting. Conversely, PVC ceilings come in a wide range of colors and finishes, including glossy, matte, or patterned surfaces. They can easily mimic the appearance of wood, stone, or other materials, allowing for creative expression in interior design, especially in spaces like kitchens and bathrooms where moisture is prevalent.

3. Ventilation and Access Think about future access for maintenance and installation of HVAC systems. Planning for potential openings in the ceiling grid can save time and effort down the line.