metal insect mesh

Latest articles

metal insect mesh

...

metal insect mesh 【metal insect mesh】

Read More

metal insect meshCompared with galvanizing, hot-dip galvanizing has lower production cost and less environmental impact than galvanizing. Because the coating obtained is thicker, hot-dip galvanizing has better protective performance than electric galvanizing, so it is an important protective coating for steel parts used in harsh working environment. Hot-dip galvanized products are widely used in chemical equipment, petroleum processing, ocean exploration, metal structure, electric power transmission, shipbuilding and other industries.

...

metal insect mesh 【metal insect mesh】

Read Moremetal insect mesh

...

metal insect mesh 【metal insect mesh】

Read Moremetal insect mesh

...

metal insect mesh 【metal insect mesh】

Read Moremetal insect mesh

...

metal insect mesh 【metal insect mesh】

Read More

metal insect mesh

Post time: 20-10-22...

metal insect mesh 【metal insect mesh】

Read Moremetal insect mesh

...

metal insect mesh 【metal insect mesh】

Read More

metal insect meshGreenhouse steel pipe is mainly made of greenhouse composite materials made of pull rod, pressure rod, column, and arch rod to cover the plastic film in a greenhouse. Wire factory introduces its this shape is circular plastic greenhouse, this greenhouse covers a large area, the effect of heat absorption is also very good, convenient to build, the cost of building a is also very low. The raw material source of greenhouse steel pipe is very rich and extensive, and the application effect is good.

...

metal insect mesh 【metal insect mesh】

Read MoreGalvanized iron wire has excellent endurance and elasticity, zinc can reach 300 grams/square meter. It has the characteristics of thick galvanized layer and strong corrosion resistance. Widely used in construction, handicrafts, wire mesh, highway guardrail, commodity packaging and ordinary civilian and other categories.

metal insect mesh...

metal insect mesh 【metal insect mesh】

Read More

metal insect meshAs a very important product of the barbed rope factory blade barbed rope can be said to have made a great contribution, but often due to the opaque processing process often do not get the trust of customers.

...

metal insect mesh 【metal insect mesh】

Read More

Popular articles

Hook mesh we usually see everywhere, in fact, hook mesh is a kind of fence, like the highway, stadium fence, road fence, etc., have hook mesh. So what are the effects and advantages of the use of hook net? Next by xiaobian to introduce us to hook the characteristics of the net.

- Weigh each reel of wire of different specifications, not less than the reel weight required in the contract, and record the value. Contact detection. No contacts are generated for each reel of wire. If there are contacts, no more than three contacts are generated for each reel. Each contact should be smooth surface treatment, the wire can not be pulled off from the contact, in line with customer packaging requirements.

- Packaging: Welding mesh is generally packed with moisture-proof paper (color is mostly gray, yellow, plus trademarks, certificates, etc.), some like 0.3-0.6mm domestic sales of small wire diameter welding mesh, because the wire is relatively soft, coupled with small rolls, customers often require baling and bagging treatment, to prevent damage caused by shipment, etc. The wire of the electric welding net is straight, and also with wavy bend (also known as Dutch net). According to the shape of the mesh surface can be divided into: electric welding mesh and electric welding mesh roll.

Latest articles

-

The welding core is the metal core of the electrode. In order to ensure the quality of the weld, there are strict regulations on the content of various metal elements in the weld core. In particular, there are strict restrictions on harmful impurities (such as sulfur and phosphorus), and the quality of the weld core metal should be better than that of the base metal. Arc welding cannot be carried out on a smooth rod without a coating. This is because the arc stability is very poor, splashing is very large, and the weld is not well formed. After long-term practice, it is gradually found that the performance of the electrode is greatly improved by coating the welding core with some mineral raw materials (i.e. electrode coating). (1) Ensure stable arc combustion, so that the welding process is normal. (2) Using the gas produced after the drug skin reaction, protect the arc and the molten pool, prevent the harmful gases in the air (such as nitrogen, oxygen, etc.) from invading the molten pool, such as these gases will cause cracks and pores in the welding material, so that the welding can not achieve the ideal effect. (3) After the drug skin is melted, slag is formed, which covers the weld surface to protect the weld metal, make the weld metal slowly cool, help the gas escape, prevent the generation of pores, and improve the structure and performance of the weld. (4) After melting, various metallurgical reactions will be carried out, such as deoxygenation, sulfur removal, phosphorus removal, etc., so as to improve weld quality and reduce alloying element burning loss.

-

-

Most of the production enterprises or large public places, they can play a defense hook mesh in the choice of time, often will hook mesh quality in position, so galvanized hook mesh this product few people are interested in, but does this show that galvanized hook mesh is not useful?

-

The large roll of galvanized wire is like the literal meaning, is wrapped in a layer of zinc on the surface of low carbon steel wire material, beautify the appearance at the same time, but also improve the corrosion resistance of galvanized wire. Zinc dissolves easily in acids and also in bases, so it is called a bi-soluble metal. Zinc changes little in dry air. In moist air, a dense basic zinc carbonate film forms on the surface of zinc.

-

The galvanizing process of galvanized wire products is a very effective metal anticorrosion method. It is also widely used in other industrial fields. The use of galvanized iron wire is very common in metal structure equipment of various industries. Due to the influence of production technology or other factors, the zinc layer of galvanized wire products will be different to a certain extent, especially ordinary galvanized can not reach the beauty of electric galvanized, the zinc layer of ordinary galvanized wire is mainly for corrosion prevention.

-

Plastic spraying is often referred to as electrostatic powder spraying. It is the use of electrostatic emitter to make plastic powder charged, adsorbed on the surface of the iron plate, and then baked at 180~220℃ to melt the powder and adhere to the metal surface. Plastic spraying products are mostly used in indoor boxes, and the paint film appears flat or matte. Spray powder mainly acrylic powder, polyester powder and so on.

Links

Cast Iron Railing Panel

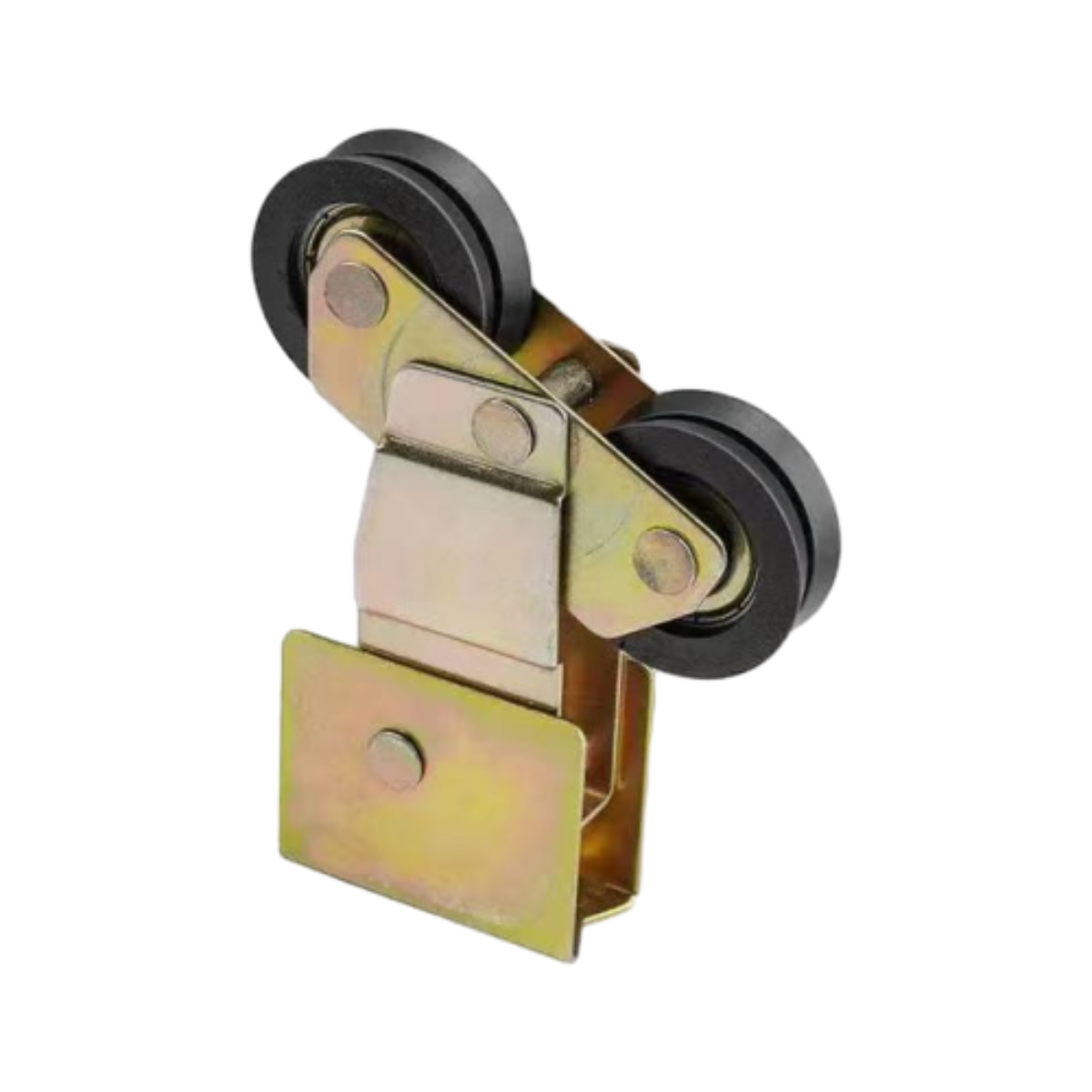

Repairing Screen Door Rollers A Step-by-Step Guide

In addition to its security features, a lockable box also provides convenience and accessibility. With a key or combination lock, you can quickly access your items whenever you need them, while keeping them protected when not in use. Some models even come with digital locks or biometric scanners for added security.

cast iron panel casting. Melting Iron The next step is to melt the cast iron in a furnace. The iron is heated to a high temperature until it becomes molten.

cast iron panel casting. Melting Iron The next step is to melt the cast iron in a furnace. The iron is heated to a high temperature until it becomes molten.Sustainability

Easy Maintenance

Do you know the characteristics of an aluminum profile window?

Sustainability

As you can see, maintaining an iron fence isn’t impossible. It takes some time, skill, and attention, but hopefully, we’ve helped you feel more confident about tackling the job. An iron fence can make a beautiful addition to your property and is the sturdy choice for keeping your assets protected from outsiders, but you also have to keep the fence itself safe from outside elements. Vigilance is key to keeping your iron fence strong and appealing for ages to come.

These rollers often include additional features like adjustable height and built-in locks for enhanced security These rollers often include additional features like adjustable height and built-in locks for enhanced security

These rollers often include additional features like adjustable height and built-in locks for enhanced security These rollers often include additional features like adjustable height and built-in locks for enhanced security types of sliding screen door rollers.

types of sliding screen door rollers. Additionally, some models incorporate advanced features such as noise reduction, weather resistance, or even self-aligning mechanisms to ensure perfect balance and smooth operation Additionally, some models incorporate advanced features such as noise reduction, weather resistance, or even self-aligning mechanisms to ensure perfect balance and smooth operation

Additionally, some models incorporate advanced features such as noise reduction, weather resistance, or even self-aligning mechanisms to ensure perfect balance and smooth operation Additionally, some models incorporate advanced features such as noise reduction, weather resistance, or even self-aligning mechanisms to ensure perfect balance and smooth operation hanging sliding door roller.

hanging sliding door roller.