6 high chain link fence

Latest articles

6 high chain link fence

...

6 high chain link fence 【6 high chain link fence】

Read More6 high chain link fence

...

6 high chain link fence 【6 high chain link fence】

Read More

6 high chain link fenceBecause the coal resources are exposed on the surface of the open pit coal mine, it is more important to protect and prevent coal theft. The erection and use of barbed rope in these places are better than other products. The barbed rope factory recommends suitable barbed rope products to everyone.

...

6 high chain link fence 【6 high chain link fence】

Read More

6 high chain link fence

Post time: 23-05-23...

6 high chain link fence 【6 high chain link fence】

Read More6 high chain link fence

...

6 high chain link fence 【6 high chain link fence】

Read More6 high chain link fence

...

6 high chain link fence 【6 high chain link fence】

Read MoreNon-proportional extension strength: It is mainly for hard steel without yield point. It is defined as the stress where the residual elongation of the standard distance part reaches 0.2% of the length of the original standard distance.

6 high chain link fence...

6 high chain link fence 【6 high chain link fence】

Read More

6 high chain link fenceAs we all know, the mechanism of resistance to atmospheric corrosion of zinc includes mechanical protection and electrochemical protection. Under the condition of atmospheric corrosion, there are ZnO, Zn(OH)2 and basic zinc carbonate protective film on the surface of zinc layer, which to a certain extent slows the corrosion of zinc. When this protective film (also known as white rust) is damaged, a new film will be formed.

...

6 high chain link fence 【6 high chain link fence】

Read More6 high chain link fence

...

6 high chain link fence 【6 high chain link fence】

Read More6 high chain link fence

...

6 high chain link fence 【6 high chain link fence】

Read More

Popular articles

Traditional wire mesh is crisscross woven into the wire, with the development of the economy, the rapid rise of all walks of life, the use of traditional wire mesh limitations gradually exposed, such as: aquaculture, to the chicken circle a cage can not be too dense, the wire can not be too thick, woven up the net wire once the mesh is too large net surface will become soft.

Post time: 11-05-23The formation process of hot dip galvanized layer is between the iron matrix and the outside of the pure zinc layer, the formation of iron-zinc alloy process, the workpiece surface in hot dip plating when the formation of iron-zinc alloy layer, so that the iron and pure zinc layer is well combined. The process of large roll galvanized wire can be simply described as: when the iron workpiece is immersed in the molten zinc liquid, the first zinc and α-iron (body-centered) solid melt is formed on the interface. This is a crystal formed by the matrix metal iron dissolved with zinc atoms in the solid state. The two metal atoms are fused with each other, and the attraction between the atoms is relatively small.

Latest articles

-

The external environment has great influence on the preservation of galvanized wire mesh. In the rainy season, it is necessary to pay attention to the air humidity of the workshop, warehouse and other departments. It is recommended to use a humidifier. Usually, the moisture absorption of book paper is larger than that of powder paper, and the pH value is higher. Generally speaking, in the normal environment of storage wire, storage time of two years is not corroded wire phenomenon. However, it should be noted that in the process of handling the iron wire, it should be handled gently to avoid the position of the coiling coil, which will cause the smooth pulling of the wire and affect the production.

-

-

Hook net raw materials are basically low carbon steel wire, stainless steel wire and aluminum alloy silk woven, and what are the characteristics and use of these raw materials? Low carbon steel wire is actually the wire we usually use, plasticity is good, good patience, pull is very good.

-

-

2, keep normal heat dissipation

-

Links

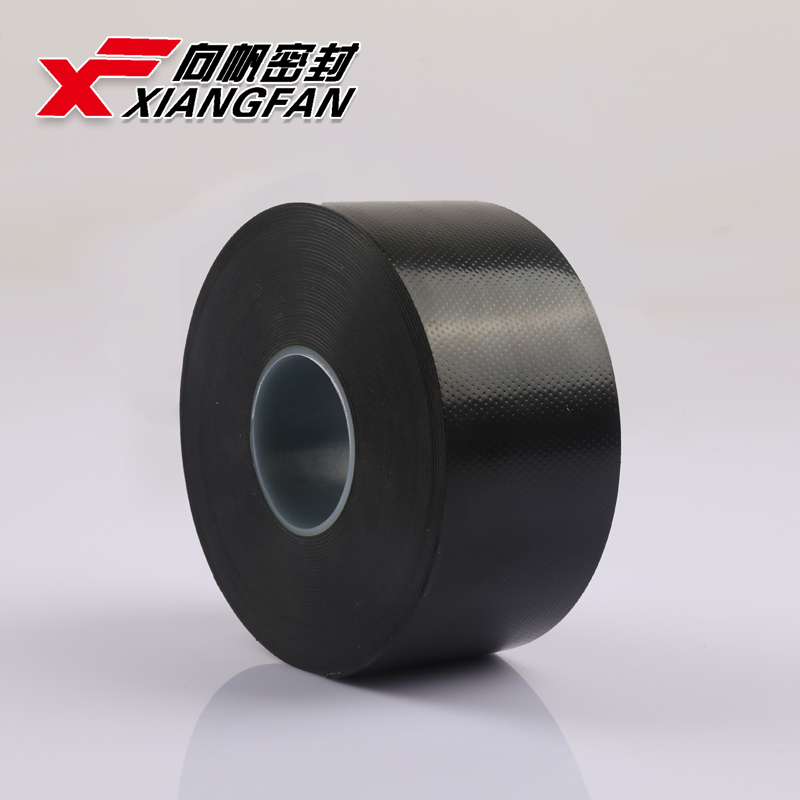

One of the key characteristics of PVC black tape is its excellent electrical insulation properties. It is widely used in electrical work to insulate wires and connections, protecting against short circuits and enhancing safety. The tape is designed to withstand a range of temperatures and resist moisture, ensuring that it retains its adhesive properties and protective capabilities even in challenging environments. This makes it an essential material for electricians and technicians who require reliable tools to ensure the safety and efficacy of their work.

- One of the main uses for gray electrical tape is in electrical work. It is commonly used to insulate and protect electrical wires and connections. The tape is designed to withstand high temperatures and provide a secure seal around exposed wires, helping to prevent electrical shocks and shorts. Its flexibility also allows for easy wrapping around curved surfaces and awkward angles, making it ideal for a variety of electrical projects.

- Temperature resistance is another important aspect of rubber flex tape. It can withstand extreme hot and cold temperatures, making it suitable for use in a wide range of environments. Whether you're working in a hot warehouse or a cold freezer, rubber flex tape will maintain its flexibility and seal effectively. This temperature resistance also ensures that the tape will not become brittle or lose its adhesion over time, maintaining its effectiveness in sealing joints and seams.

FREQUENTLY ASKED QUESTIONS ABOUT POLYETHYLENE RUBBER TAPES

Without the proper protection provided by the car harness tape, these wiring harnesses can be susceptible to damage from heat, moisture, and vibrations. This can lead to potential short circuits, electrical malfunctions, and even fires.

Yes, 3M Rubber Electrical Tapes are engineered to repel moisture, making them perfect for outdoor applications. If wrapped properly, self-fusing rubber tapes can provide a watertight seal. To further protect against harsh environments, it's recommended to overwrap the rubber tape with durable vinyl electrical tape. These tapes are also built to withstand high temperatures, making them suitable for applications near motors, heat vents, or blast furnaces.

The Versatile Utility of Flex Tape A Comprehensive Look at Flex Tape White 4x5

Understanding Butyl Rubber Rolls Properties, Applications, and Benefits

The tape fuses or seals itself to create a waterproof and airtight layer when stretched and wrapped around objects.

Resistant to cold and heat, with an operating temperature range from -20°C to approximately 250°C