weld mesh panels for sale

Latest articles

weld mesh panels for sale

...

weld mesh panels for sale 【weld mesh panels for sale】

Read More

weld mesh panels for sale

Post time: 16-12-22...

weld mesh panels for sale 【weld mesh panels for sale】

Read More

weld mesh panels for saleDomestic iron wire factory has been able to consume wire rope, radial low steel wire, umbrella steel wire, spring steel wire, bicycle saddle spring steel wire and other products. In the 1980s, hot – plated low carbon steel wire, fan net cover steel wire, carbon structure steel wire, bed steel wire and so on were also published. The elongation of wire is increased after annealing. Make the product more soft and increase the scope of application of the wire.

...

weld mesh panels for sale 【weld mesh panels for sale】

Read MoreFor key and important parts with tensile strength greater than 1034Mpa, the stress should be removed at 200±10℃ for more than 1 hour before plating, and for carburized or surface hardened parts, the stress should be removed at 140±10℃ for more than 5 hours. The cleaning agent used for cleaning shall have no effect on the binding force of the coating and no corrosion on the substrate. Acid activation Acid activation solution should be able to remove corrosion products and oxide film (skin) on the surface of parts without excessive corrosion on the matrix.

weld mesh panels for sale...

weld mesh panels for sale 【weld mesh panels for sale】

Read More

weld mesh panels for sale

Post time: 19-05-23...

weld mesh panels for sale 【weld mesh panels for sale】

Read Moreweld mesh panels for sale

...

weld mesh panels for sale 【weld mesh panels for sale】

Read More

weld mesh panels for saleLarge hexagonal net called stone cage net, mainly used for mountain preparedness protection, hydraulic construction, etc. Small wire hexagonal net is used as a good material for breeding, will twist the hexagonal net in the welding of the iron frame on the hexagonal net welding into chicken cage, pigeon cage, rabbit cage and other cage, hexagonal net is an excellent material for breeding with the net.

...

weld mesh panels for sale 【weld mesh panels for sale】

Read Moreweld mesh panels for sale

...

weld mesh panels for sale 【weld mesh panels for sale】

Read MoreThe main raw materials of blade barbed wire are galvanized wire and galvanized sheet. Because the price of galvanized sheet is more expensive than galvanized wire, it is directly reflected in the price of blade barbed wire sales. There is also the difference in processing technology also leads to the difference in the price of the blade barbed rope. The traditional barbed rope is mechanically twisted, with relatively small labor consumption and high production efficiency. But the blade barbed rope is after the second mechanical processing in the artificial processing operations to appear. Therefore, there is a big gap between labor force and production efficiency. These factors lead to the price of the blade barbed rope is more expensive main factors.

weld mesh panels for sale...

weld mesh panels for sale 【weld mesh panels for sale】

Read Moreweld mesh panels for sale

...

weld mesh panels for sale 【weld mesh panels for sale】

Read More

Popular articles

Paint on the galvanized layer, the binding force between each other and the baking temperature of the paint has a great relationship, after galvanized coating alkyd paint, adhesion is no problem. Galvanized amino paint, paint adhesion is not good. Do two bottom two surface, adhesion is ok, if the two bottom two surface to two bottom three surface, that is, more paint, more baking once, again test adhesion is very poor, poor to the paint from the galvanized layer of pieces torn off.

The weight calculation method of hexagonal net is: the weight calculation method of hexagonal net: silk meridian.× silk meridian.× base x length x width ÷2=kg base: 1/2′=2.151′=1.273/4′=1.65/8′=1.875/4′=1.091′x1/2′ : 3′=0.4 silk warp. x silk warp. X 2x length x width ÷8×3=kg

Latest articles

-

-

Before wall plastering, the wall column is connected to the gap construction wire mesh, which can play a certain strengthening and heat preservation effect. The mesh is hung on the interface surface of different grassroots, and the length of each side should meet the requirements of 100mm, so as to prevent shrinkage and cracking caused by different grassroots. Mesh wire diameter can also determine the effect and efficiency of construction, mesh fine laid up convenient soft, high construction efficiency; Of national standard can assure quality, but laid respect is inferior to fine construction fast.

-

-

Post time: 26-09-22 -

During this process, each time the wire is pulled over, the surface hardens due to the high friction temperature. So basically every time you pull it you have to annealing it in the furnace. On the one hand, it is to reduce the surface hardness. On the other hand, during the process of wire pulling, only the surface is deformed, and the center is unchanged. So there’s a lot of stress inside. Therefore, it is necessary to rely on annealing to eliminate the internal stress, so that the wire becomes soft again to eliminate the stress before being drawn again.

-

Links

- There are a few key factors to consider when selecting needles for upholstery sewing. The first factor to consider is the size of the needle. Needles come in various sizes, ranging from larger sizes for heavy-duty fabrics to smaller sizes for lighter weight materials. It's important to choose a needle size that is appropriate for the fabric you will be working with. Using the wrong size needle can result in skipped stitches or broken threads.

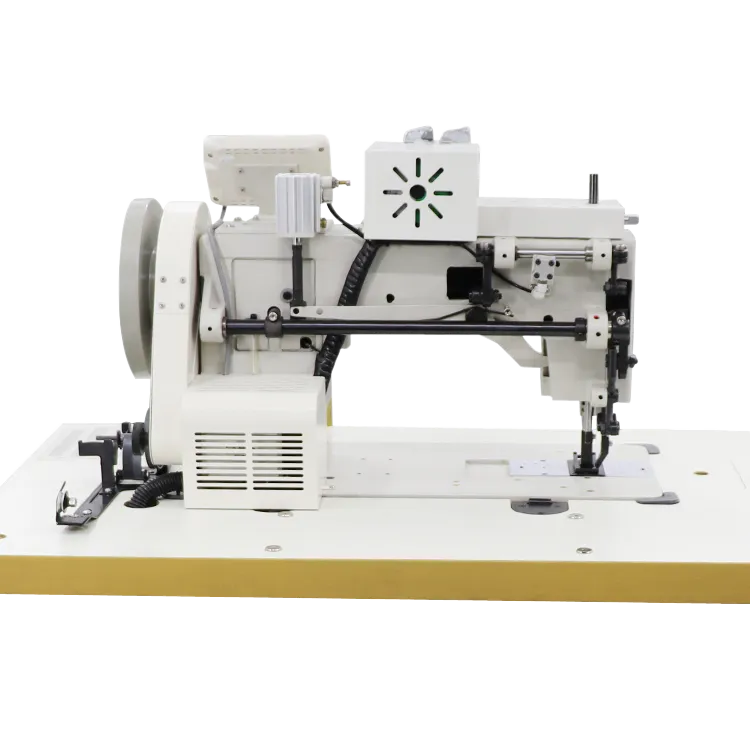

For those who appreciate a blend of quality and affordability, the Bernette B37 is an excellent choice. This model is built for durability and offers an impressive 50 built-in stitches, including useful utility stitches and decorative options. The B37 features a clear, easy-to-read LCD screen that allows for straightforward stitch selection and customization. Its strong motor and robust construction make it capable of handling heavy materials, making this machine a worthy investment for various sewing needs.

The future will also likely see the increased incorporation of smart technology, allowing for real-time monitoring and maintenance alerts. This shift will not only enhance efficiency but also promote sustainability by reducing waste and optimizing resource use.

- Before starting your actual project, practice on scrap fabric. This helps you get a feel for the double needle and make necessary adjustments to the tension or stitch length.

CNC stitching machines utilize computerized controls to automate stitch placement, needle movement, and thread tensioning. Unlike traditional sewing machines, which require manual operation and skillful craftsmanship, CNC machines enhance productivity by minimizing human error and maintaining consistent quality across large production runs. These machines are programmed using CAD (Computer-Aided Design) software, enabling manufacturers to create complex patterns and designs with ease.

Many long arm quilting machines come equipped with advanced features like computerized stitching, adjustable stitch length, and a variety of quilting patterns. These enhancements streamline the sewing process, allowing for intricate designs and consistent results. The machines can be quite an investment, but for serious quilters, the time savings and quality of work produced are often well worth it.

Discover the Double Needle Walking Foot Sewing Machine A Perfect Addition to Your Sewing Arsenal