square iron net

Latest articles

Slowly through the axial flow fan or exhaust hole directly discharged to the sand blasting room, so that the power of dust discharge is low. And in the discharge of dust because there is no further treatment, so the discharge of dust will seriously pollute the sandblasting room and the surrounding environment, the health of the site staff will also harm.

square iron net...

square iron net 【square iron net】

Read MoreGalvanized wire can be seen as iron wrapped in carbon, when extinguished, the surface is comparable to shallow carbon can contact with oxygen, produce carbon dioxide gas, will wrap it in iron (this is a molten state) radiation in. The more carbon there is in the galvanized wire, the more likely it is to spark. The iron-encased carbon is like dynamite in a dynamite bag, blowing the iron away from time to time.

square iron net...

square iron net 【square iron net】

Read Moresquare iron net

...

square iron net 【square iron net】

Read More

square iron netBridge protection system generally do not need to be specially installed special drainage system, the use of hexagonal mesh made of gabion mesh box, the inside of the filler are selected stones, these stones are not easy to wear, and between the stones and stones will retain some gaps, so it is very good to meet the drainage requirements.

...

square iron net 【square iron net】

Read Moresquare iron net

...

square iron net 【square iron net】

Read MoreDetermine the size of the dog cage based on the dog’s actual adult size. In general, the cage should be three times the size of the dog’s body and give him enough room to turn around and so on.

square iron net...

square iron net 【square iron net】

Read More

square iron netAfter annealing, iron wire will become softer and more flexible. Iron is a more active metal, and more active than hydrogen, so it is a good reducing agent. At room temperature, iron is not easy to react with oxygen, sulfur, chlorine and other non-metallic elements in dry air, its production cost is low, the use and scale is relatively wide, better protective function, so it is an important material for steel parts used in strict working environment.

...

square iron net 【square iron net】

Read Moresquare iron net

...

square iron net 【square iron net】

Read More2.25*2.25mm 10 meters per kilogram

square iron net...

square iron net 【square iron net】

Read More

square iron netThe number of each bundle of the blade barbed rope is 50, which is reduced by hydraulic compression and thus more convenient for loading and unloading. The forklift can load and unload easily. Under normal circumstances, when the export will be packaged and sold, so that the volume occupied in the container is relatively small, it can be easily placed and will not take up much space.

...

square iron net 【square iron net】

Read More

Latest articles

-

3. For temporary protection, breeding chickens and ducklings, etc., it is recommended that you choose products with a wire diameter of 2mm.

-

The above is Xiaobian for you to introduce the characteristics of spray blade rope. The mechanical strength, adhesion, corrosion resistance and aging resistance of the spray blade are widely used.

-

-

Due to the implementation of the grassland contract operation obligation system, herdsmen have a high capacity to strengthen and raise their stainless steel barbed rope fence net in grassland pastoral areas, forming the phenomenon of high density and high height of stainless steel barbed rope fence net in grassland pastoral areas, which is destructive and even destructive to the survival of wild animals.

-

Bird cage placement and attention

-

Links

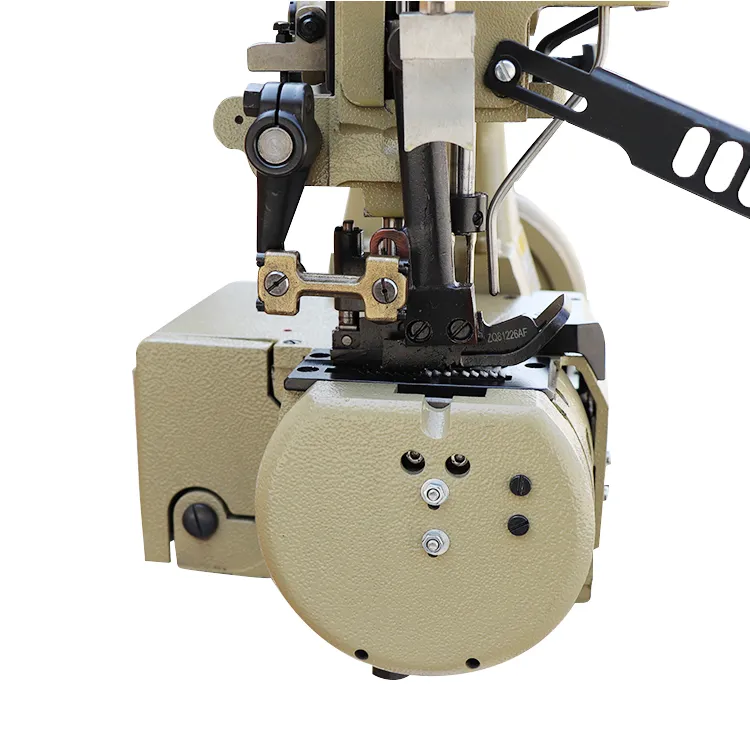

What to Consider When Purchasing an Industrial Overlocker

Thick Threads for Sewing Leather The Perfect Choice for Durable Craftsmanship

6. Enhancing Decorative Elements

When it comes to sewing canvas, selecting the right thread is just as important as picking the correct fabric and sewing machine. Heavy-duty thread is an essential component for achieving durable, high-quality seams that can withstand the rigors of outdoor use, crafting, and upholstery. In this article, we will explore the characteristics of heavy-duty thread, its types, and tips for choosing the right one for your canvas projects.

Maintenance and Care

- Despite its many advantages, CNC machine sewing is not without its challenges. For example, the initial investment in purchasing and setting up a CNC machine can be substantial, and there may be a learning curve for operators who are unfamiliar with the technology. Additionally, maintenance and repair of CNC machines can be complex and require specialized knowledge.

In addition to the garment industry, this machine finds applications in home sewing projects, enabling hobbyists to create professional-grade finishes on their creations. Whether making a simple top or a complex garment, the double needle chain stitch machine provides the versatility and performance that sewers crave.

In conclusion, the floating foot sewing machine has redefined the sewing landscape by providing enhanced precision, flexibility, and user-friendly features. Whether you are a budding enthusiast or a seasoned professional, integrating this innovative sewing tool into your crafting toolkit can significantly elevate your sewing experience. As technology continues to evolve, it’s exciting to foresee what other advancements will shape the future of sewing, but for now, the floating foot machine stands out as a definitive asset in the world of textiles. Embracing this technology not only streamlines the sewing process but also opens up endless possibilities for creativity and craftsmanship in every stitch.

Conclusion

The price of a cylinder bed sewing machine can vary significantly based on several elements, including brand, features, functionality, and the machine's specific purpose. On average, a standard cylinder bed sewing machine can cost anywhere from $1,000 to $5,000. High-end models with advanced features or greater functionality might exceed this range, potentially reaching prices above $10,000.

A baffle sewing machine is specifically designed to create baffles in various types of materials, which are essential for products like sleeping bags, jackets, and comforters. The term baffle refers to the construction technique that involves dividing a material into compartments, which helps to optimize insulation and create a structured shape. Traditional sewing machines do not possess the capability or efficiency to handle such specialized tasks, leading to the development of the baffle sewing machine.

In addition, hand sewing machines encourage creativity and innovation. Craftsmen have the freedom to experiment with various stitching techniques and decorative elements, resulting in unique and individualized pieces that reflect their personal style. This artistic expression is often lost in mass production, making hand-sewn upholstery a valuable and sought-after commodity.

Sewing Machine Specials

Another significant benefit is versatility; lock stitches can be used for both straight and decorative stitches, allowing for creativity in sewing projects. Lastly, sewing machines designed to create lock stitches are typically user-friendly, making them accessible for beginners while also offering advanced features for experienced sewists.

industrial sewing machine needles for leather. The size of the needle refers to the diameter of the needle shaft, with larger numbers indicating thicker needles. For sewing leather, it is recommended to use needles with sizes ranging from 14 to 18, as these sizes are strong enough to penetrate through the material without causing damage.

In summary, the typical double needle sewing machine is a fantastic addition to any sewist’s toolkit, providing efficiency, versatility, and professional-quality results. Its ability to create two lines of stitching in a single pass not only saves time but enhances the aesthetic appeal of the finished product. Whether for commercial applications or personal projects, mastering the double needle technique can significantly elevate one’s sewing capabilities and creativity. As the sewing industry continues to evolve, the double needle sewing machine remains a trusty companion for those looking to push the boundaries of fabric artistry.

Heavy duty machines typically have higher maximum sewing speeds, around 1500 stitches per minute, versus 1000-1200 stitches per minute for standard machines. Again, this allows them to work through heavy fabrics more efficiently. However, heavy duty machines also tend to sew better at slower speeds, in the 500-800 stitch per minute range, for optimal control through thick seams. So they provide a wider speed range to suit the fabric.

In conclusion, single heavy duty sewing machines offer a range of advantages that cater to a diverse audience of sewers. Their durable construction and powerful motor make them ideal for handling robust fabrics, while their versatility and speed enhance the sewing experience. Whether you are a professional seamstress or a dedicated hobbyist, investing in a heavy duty machine can elevate your sewing projects to new heights. By providing reliability and efficiency, these machines are a valuable asset in any sewing room, enabling users to embrace their creativity and produce high-quality work with confidence.

4. Shoe and Garment Manufacturing: For producing apparel and footwear that require hardwearing and tear-resistant materials like workwear, cold weather gear and safety boots, the machines demonstrate unique processing capabilities.

The Importance of Bulk Bag Sewing Machines in Modern Manufacturing

Exploring the Benefits of Double Needle Sewing Machines for Leather

Selecting the right heavy-duty sewing machine is crucial for achieving optimal results in your sewing projects. The machines highlighted above represent some of the best-rated options available today, each offering unique features to cater to different needs and preferences. Whether you're a beginner or an experienced sewist, investing in a quality heavy-duty sewing machine can greatly enhance your sewing experience, allowing you to take on a wide range of projects with confidence. Happy sewing!

Size and Portability

Benefits for Manufacturers

automatic shoe sewing machine

5. Adjustable Presser Foot Pressure This feature allows users to modify the pressure against the fabric, making it easier to work with different thicknesses and types of materials.

beginner heavy duty sewing machine

For those who want a more industrial-grade machine, the JUKI TL-2010Q offers unmatched performance for heavy fabric sewing. With its high-speed stitching capabilities and precision, it’s perfect for serious tent makers looking for professional quality.

Moreover, with the rise of sustainability in fashion, automatic button sewing machines can play a significant role. By enhancing efficiency and reducing waste, they allow businesses to operate more sustainably. For instance, fewer mistakes in button placement mean less fabric scrapping and reduced resource consumption overall. This aligns with the growing consumer demand for eco-friendly production practices, ultimately benefiting the environment.

Applications in Various Industries

Next comes the most critical part stitching. Hand stitching is primarily done using a method known as the saddle stitch, a technique that employs two needles and a single length of thread. This method is favored for its strength and durability, ensuring that the seams can withstand wear and tear over time. The process involves creating holes with an awl, allowing for precise and evenly spaced stitches, which contribute to the item’s overall aesthetic.

Sewing, a craft steeped in tradition and art, has evolved over centuries into a diverse array of specialized techniques. Each method offers unique possibilities, allowing artisans to express creativity and precision. The term special sewing encompasses a range of advanced techniques designed for various applications, from bespoke garments to intricate home decor. In this article, we will delve into the world of special sewing, exploring its techniques, tools, and the joy it brings to both hobbyists and professionals.

Another important aspect of maintenance is keeping your machine properly adjusted and calibrated. Check the tension of the thread regularly and make any necessary adjustments to ensure that your stitches are even and balanced. Additionally, keep an eye on the condition of your needles and replace them as needed to prevent skipped stitches or damage to your fabrics.

The Importance of Industrial Bag Closing Machine Heads in Modern Manufacturing

Jumbo bag sewing machinery is specifically designed to meet the challenges of assembling large and heavy-duty bags. Typical sewing machines operate at high speeds and can handle the tough, thick materials used in jumbo bags. This machinery not only increases production efficiency but also ensures that the seams are durable and reliable, which is essential for the safety and integrity of the contents being transported.

In today's fast-paced industrial landscape, efficiency and precision are paramount. One piece of technology that has gained prominence in the packaging sector is the automatic bag closer machine. These machines play a crucial role in enhancing production capabilities, reducing labor costs, and ensuring product quality.

One of the primary advantages of the Union Lockstitch Sewing Machine is its reliability. Manufacturers and tailors appreciate its ability to handle various fabrics without compromising on stitch quality. It maintains consistent performance even during long hours of operation, making it an efficient option for those in the textile industry.

union lockstitch sewing machine