What are FIBC Spout Rosettes?

Convenience for Beginners

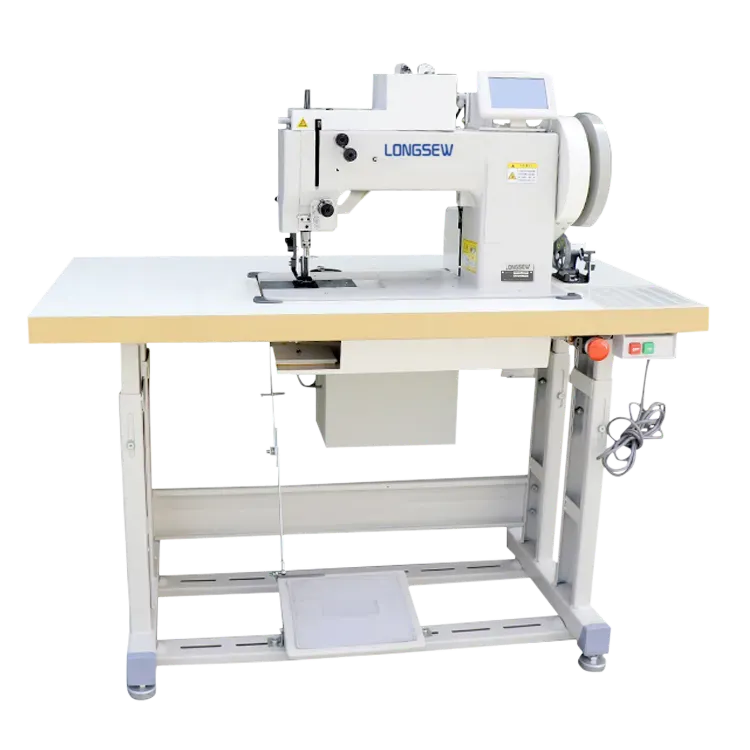

On the higher end, professional-grade fully automatic sewing machines can cost anywhere from $1,500 to over $5,000. These models are equipped with a plethora of features designed for advanced sewers and professionals. They may include high-speed stitching, extensive embroidery designs, customizable settings, and superior build quality. Some high-end machines even offer computerized systems that can connect to design software for creating unique patterns and models.