ring shank coil siding nails

Latest articles

ring shank coil siding nails

Post time: 17-06-24...

ring shank coil siding nails 【ring shank coil siding nails】

Read MoreAnnealing is to restore the plasticity of wire, improve the tensile strength of wire, hardness, elastic limit, etc., the wire after annealing is called annealing wire. In the production process of annealing wire, it is very important to ensure the quality of the finished wire, make the wire have certain strength and suitable degree of soft and hard. The annealing temperature is between 800 ℃ and 850℃, and the length of furnace tube is lengthened appropriately for enough holding time.

ring shank coil siding nails...

ring shank coil siding nails 【ring shank coil siding nails】

Read Morering shank coil siding nails

...

ring shank coil siding nails 【ring shank coil siding nails】

Read Morering shank coil siding nails

...

ring shank coil siding nails 【ring shank coil siding nails】

Read MoreGalvanized wire to galvanized uniform, a body is now its cross section, the second is the longitudinal uniformity. In the actual operation process, such as the jitter of steel wire, the surface of the pot scum and other reasons will cause galvanized wire surface galvanized layer accumulation, should try to solve the problem.

ring shank coil siding nails...

ring shank coil siding nails 【ring shank coil siding nails】

Read More

ring shank coil siding nails

Post time: 27-04-23...

ring shank coil siding nails 【ring shank coil siding nails】

Read Morering shank coil siding nails

...

ring shank coil siding nails 【ring shank coil siding nails】

Read Morering shank coil siding nails

...

ring shank coil siding nails 【ring shank coil siding nails】

Read More

ring shank coil siding nailsThe physical methods mainly include manual rust removal and mechanical rust removal, chemical rust removal is generally the use of pickling method, practical application, usually according to the appearance of the workpiece rust status and different post-treatment process, choose different rust removal methods, among which pickling rust cleaning is more commonly used. That is, the iron and steel workpiece with oxide skin or rust is etched in the acid lotion, mainly to remove the oxide or rust layer on the surface of the steel.

...

ring shank coil siding nails 【ring shank coil siding nails】

Read More

ring shank coil siding nailsThe characteristics of hexagonal wire mesh: strong structure, flat surface, with good corrosion resistance, oxidation resistance and so on.

...

ring shank coil siding nails 【ring shank coil siding nails】

Read More

Popular articles

- Technical product wire, choose a wire special processing, no broken end, zinc amount uniform bright, general quotation slightly expensive. Galvanized silk also contains sprinkling: one plate per volume weight of about 100kg-1000 kg, mainly suitable for industry, agriculture, animal husbandry. Strong corrosion ability, solid coating and other characteristics.

- At present, it is recognized that the best surface treatment method for rust prevention is to make dacron rust. Generally, auto parts have been used this method for rust prevention. The salt water test generally lasts more than 96 hours. But if the hardware is used in very poor conditions, there are also people who use “asphalt” which is tar to do the surface treatment.

Small and medium-sized cat cages, dog cages and fences are mostly made of pure iron wire, wire diameter is generally between 2-5mm. Of course, the larger the cage, the thicker the wire, because the larger cage needs to withstand more force.

Latest articles

-

-

-

Zinc dipping time should be adjusted according to the thickness of wire diameter. The method of adjustment is to use the lead screw above the zinc pot, the length of the distance to the ceramic sinking roller. Thick wire diameter zinc dipping time should be long, fine wire diameter zinc dipping time should be short, zinc dipping length is in the range of 2~3.5m, which is also to reduce the zinc consumption of steel wire, is an aspect of maintaining the uniformity of zinc layer.

-

When in use, wrap into a roll cage. First, its ventilation is good, conducive to the air drying of corn; Second, occupy a small space, convenient drying, good air permeability, light transmission; Third, beautiful and strong, reusable, cost-effective. And in the storage process, it is easy to cover in rain and snow weather to avoid the deterioration of corn mold.

-

Stainless steel barbed rope is often used in various engineering projects because of its good anticorrosion ability, but it is difficult to be accepted by ordinary families because of its high price. So what material of barbed rope has better anticorrosion ability?

-

The uniformity of galvanized wire is reflected in what aspects:

Links

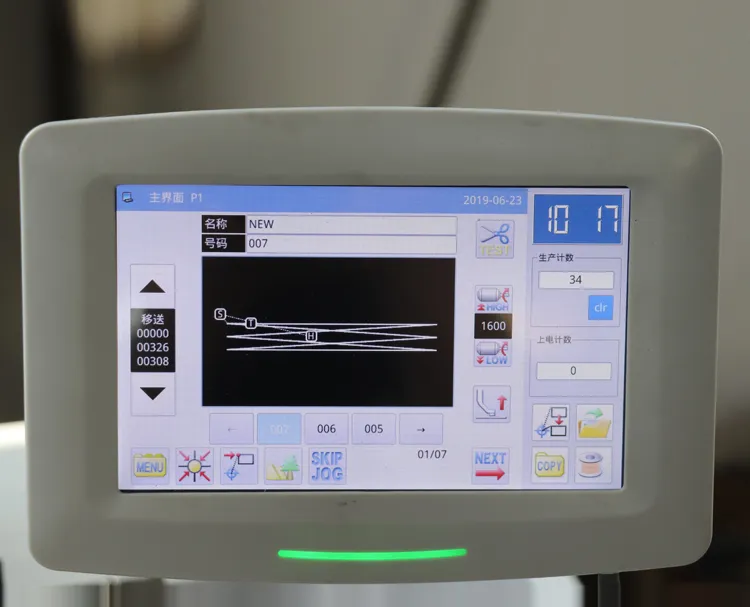

In summary, multi-needle quilting machines represent a significant advancement in the quilting community, providing efficiency, versatility, and creative freedom. As technology continues to enhance traditional crafts, these machines allow quilters to push the boundaries of their artistry. Whether you are a novice eager to learn or a seasoned professional looking to streamline your process, investing in a multi-needle quilting machine could revolutionize your approach to quilting. Embrace the possibilities that these machines offer, and unlock a new world of creativity in your quilting journey.

Key Features and Functionality

Exploring the Double Needle Stretch Stitch A Comprehensive Guide

Choosing the Right Sewing Machine

Whether you're a seasoned embroiderer or just starting out, double thread chain stitch is a fun and easy stitch to master. With a little practice, you'll be able to create beautiful and intricate designs with this versatile stitch. So grab your embroidery hoop, floss, and needle, and start stitching!

For those in the market, there are various models of manual leather sewing machines available for sale. When searching, consider factors such as the type of leather you’ll be working with, the machine’s stitch options, and the level of portability that suits your lifestyle. Additionally, checking for user reviews and seeking recommendations from seasoned leatherworkers can help guide your purchase.

In conclusion, leather sewing machine companies represent a vital link in the craftsmanship and production of leather goods. They combine innovation, sustainability, and community support, ensuring that both new and experienced artisans can create high-quality products. As the demand for leather continues to grow, these companies are not just manufacturers; they are enablers of creativity, helping artisans around the world transform their visions into reality. Whether it's a custom leather handbag or a pair of finely crafted shoes, the journey of creation often begins with the right sewing machine, making these companies an indispensable part of the leather goods industry.

Lock sewing, often referred to as “lock stitch sewing,” is a technique that utilizes two threads—one from the needle and the other from the bobbin—to create a secure stitch. The stitches interlock at the seam, making it less prone to unraveling. This method is widely used in both industrial and home sewing machines because of its efficiency and the neat finish it provides.

The environmental impact of footwear production is an ongoing concern, with traditional methods often leading to waste and excess material use. Automatic shoe sewing machines contribute to more sustainable practices by optimizing material usage and reducing off-cuts. Advanced software solutions are also being integrated to track material consumption and streamline processes further, allowing manufacturers to adopt more eco-friendly practices.

pattern sewing machine price. Higher-priced pattern sewing machines are typically made from more durable materials and offer more features and functions than lower-priced models. While it may be tempting to opt for a cheaper machine, investing in a higher-quality model will likely save you money in the long run, as it will be more reliable and last longer.

Conclusion

- Built-in Stitch Options Depending on your projects, you may want a machine that offers different stitch types, including straight, zigzag, and decorative stitches.

Benefits of Using Long Arm & High Arm Zigzag Sewing Machines

Key Features to Look For

The Cost of Zigzag Sewing Machines An Overview

Why Use a Heavy-Duty Sewing Machine? Its Top Uses

The design of the bobbin shuttle hook has evolved significantly over the years. Early sewing machines used a simple curved hook, which, while functional, lacked the efficiency and speed of modern designs. The introduction of the rotary hook mechanism revolutionized the sewing industry. This design allowed for faster sewing speeds, better stitch quality, and reduced the noise associated with older machines. The intricacies of modern bobbin shuttle hooks are a testament to years of innovation and engineering, culminating in a component that is both robust and efficient.

bobbin shuttle hook

The World of Multi-Needle Quilting Machines

container bag sewing machine. This is important in the production process, where time is of the essence, and a high volume of bags needs to be sewn in a short amount of time. The container bag sewing machine is equipped with a large bobbin and thread capacity, allowing for long hours of uninterrupted sewing.

What is a Lockstitch Sewing Machine?

In conclusion, PP bag stitching machines are integral to the packaging landscape, combining efficiency, precision, and cost-effectiveness. As industries continue to seek ways to enhance productivity while adhering to sustainability practices, the significance of these machines will only grow. Understanding their evolution and operation helps appreciate the vital role they play in ensuring that products are delivered safely and securely to consumers worldwide. As technology continues to advance, the future of PP bag stitching machines looks promising, with further innovations on the horizon to enhance their capabilities and efficiency.

In a manufacturing context, overlockers are essential for maximizing efficiency. They allow for faster production rates by combining multiple steps into one process—sewing, trimming, and finishing can all happen simultaneously. This capability is particularly advantageous in high-volume garment production, where maintaining consistency and speed is critical.

Understanding Leather

The applications of the walking needle sewing machine are vast and diverse. In the fashion industry, it is commonly used for constructing garments, as it allows for precise seams and finishes. Craftspeople appreciate its utility in creating bags, upholstery, and home decor items. Quilters especially favor walking needle machines for their ability to handle layered fabrics without compromising accuracy.

Lastly, the scalability of GSC367TD cannot be overlooked. As organizations grow, their technology needs often change. GSC367TD is built with scalability in mind, allowing businesses to expand their capabilities without overhauling their existing systems. This flexibility makes it an ideal choice for both small startups and large enterprises looking to adapt to changing market dynamics.

Understanding the Walking Foot

The Essential Role of Woven Sack Bag Sewing Machines in Modern Manufacturing

Moreover, the walking foot mechanism helps to feed all layers of fabric evenly, which is crucial when sewing thicker materials. This ability reduces the risk of uneven seams and ensures a professional appearance in the final product.

Benefits of Using a Double Needle Sewing Machine

In the world of textile manufacturing, few innovations have had as profound an impact as the Union Lockstitch sewing method. This invention, which revolutionized the way fabrics are joined together, plays a critical role in various applications, from garment production to upholstery and beyond. The Union Lockstitch is a specific type of lockstitch created primarily for its durability, versatility, and efficiency.

Home textile manufacturers also benefit from zig zag embroidery machines, using them to enhance products like bed linens, curtains, and towels. As consumer preferences shift towards personalized and embellished home goods, these machines offer the capabilities necessary for innovation in design.

1. Improved Stitch Quality Using a zigzag presser foot ensures that the zigzag stitches are uniform and even, preventing issues such as skipped stitches or uneven tension.

Tips for Using a Zigzag Presser Foot

Additionally, the trend towards automation in various industries suggests that CNC machine sewing may become a standard practice in textile manufacturing. As costs decrease and technology becomes more accessible, smaller businesses will also benefit from CNC capabilities.