w2 9 wire mesh

Latest articles

w2 9 wire mesh

...

w2 9 wire mesh 【w2 9 wire mesh】

Read MoreHexagonal mesh is metal wire woven Angle mesh (hexagonal) made of barbed wire, the use of wire diameter is different according to the size of the hexagonal.

w2 9 wire mesh...

w2 9 wire mesh 【w2 9 wire mesh】

Read More

w2 9 wire mesh

Post time: 02-06-22...

w2 9 wire mesh 【w2 9 wire mesh】

Read More

w2 9 wire mesh...

w2 9 wire mesh 【w2 9 wire mesh】

Read Morew2 9 wire mesh

...

w2 9 wire mesh 【w2 9 wire mesh】

Read Morew2 9 wire mesh

...

w2 9 wire mesh 【w2 9 wire mesh】

Read Morew2 9 wire mesh

...

w2 9 wire mesh 【w2 9 wire mesh】

Read MoreChoose a cage with a reasonable structure, such as a tray under the cage, so that the dog can relieve itself directly inside the cage. It’s easy for the owner to clean up.

w2 9 wire mesh...

w2 9 wire mesh 【w2 9 wire mesh】

Read Morew2 9 wire mesh

...

w2 9 wire mesh 【w2 9 wire mesh】

Read Morew2 9 wire mesh

...

w2 9 wire mesh 【w2 9 wire mesh】

Read More

Popular articles

Post time: 12-07-22- Galvanized wire is coated with a layer of stable zinc on the outside of the wire, and the zinc layer is used to protect the wire and make the service life of the wire longer. In the production of galvanized wire, the wire should be pickled. Pickling is to use some acid mist or acid liquid to wash away some oxides on the surface of iron, that is, rust, and some other corrosion, to achieve the purpose of cleaning iron, so that zinc will fall off when galvanized.

- The common specifications of small hexagonal mesh in production are: the width is 1.22m, and the commonly used width is generally 1m. In terms of length, there are basically no restrictions on small hexagonal nets. 1-100 meters can be produced. The production wire diameter of small hexagonal mesh is generally No. 27 wire to No. 18 wire, and the aperture size is 0.95cm-5.08cm.

- The material of wire mesh can choose galvanized wire, stainless steel wire, copper wire, coated wire, lacquer wire, etc., different materials are used in different fields, such as construction, culture, decoration, etc.

Latest articles

Links

5. Low Maintenance Requirements

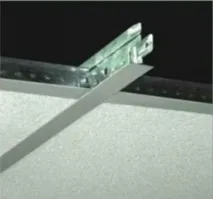

After the main tees have been installed, the cross tees are added, completing the grid. Finally, ceiling tiles or panels are placed within the grid, creating a uniform and polished look. This installation process, while straightforward, requires precision to ensure both aesthetic appeal and functionality.

In summary, ceiling attic access doors are essential components that greatly enhance the functionality of a home. By providing easy access to valuable attic space, these doors facilitate storage solutions and can contribute to the home's overall efficiency. As homeowners consider their options, they should weigh the pros and cons of different types of access doors, ensuring they select one that best meets their needs. With the right attic access door, homeowners can enjoy the full benefits of their attic space while maintaining a clutter-free and organized living environment.

The Future of T-Grid Ceilings

External waterproof access panels are pivotal in multiple industries. In the construction sector, they are commonly used in exterior walls and roofs, providing access to electrical systems, plumbing lines, and HVAC equipment. In the food and beverage industry, these panels ensure sanitary access points, allowing for quick inspections while adhering to health regulations. Additionally, in industrial settings, waterproof access panels are indispensable for controlling moisture levels in sensitive environments such as data centers and laboratories.

In conclusion, cross tees play a fundamental role in the installation and functionality of suspended ceilings. Their versatility, acoustic benefits, accessibility to utilities, and aesthetic contributions make them an essential component in modern ceiling design. However, careful consideration of load capacity, alignment, and compliance with regulations is crucial to achieving the desired results. With the right approach, cross tees can significantly enhance the performance and appearance of any space.

Safety is a primary concern in building design, and mineral fibre ceilings excel in this area. These materials are non-combustible, meaning they do not ignite and can withstand high temperatures without contributing to the spread of fire. This property is particularly important in public buildings, where compliance with safety regulations is mandatory. The ability of mineral fibre to resist fire can provide crucial time for evacuation and minimize damage during emergencies.

1. Aesthetic Integration One of the key advantages of circular ceiling access panels is their ability to blend in with the ceiling design. Their rounded shape can be less distracting than rectangular panels, creating a more streamlined look that can complement various architectural styles.