1 2 inch welded wire mesh

Latest articles

1 2 inch welded wire mesh

...

1 2 inch welded wire mesh 【1 2 inch welded wire mesh】

Read More

1 2 inch welded wire meshBecause of the large size of the barbed rope, the rope factory is used to packing. If you do not pack, then a load of blade rope can not hold many pieces, but also relatively occupy space and easy to be lost in the process of transportation.

...

1 2 inch welded wire mesh 【1 2 inch welded wire mesh】

Read More5. The bird cage should be sprayed with transparent wood environmental protection paint every 1-2 years. This protects the cage’s skeleton from the effects of weathering.

1 2 inch welded wire mesh...

1 2 inch welded wire mesh 【1 2 inch welded wire mesh】

Read More

1 2 inch welded wire meshAfter the corrosion of impregnated hexagonal wire mesh, the original characteristics will be lost, and the shape, color and mechanical properties will be changed, resulting in equipment damage, pipeline leakage, etc., specifically, it is easy to break and lose the original protection function. Usually, there are three kinds of metal corrosion: physical corrosion, chemical corrosion, electrochemical corrosion, corrosion in addition to the chemical properties and organizational structure of the metal itself, but also related to the surrounding medium, such as wet environment is easier to rust than dry environment, more impurities than impurities less easy corrosion, high temperature conditions than low temperature conditions easy corrosion. After understanding these, we can effectively prevent the corrosion of impregnated six-sided wire mesh, prolong the service life of the product.

...

1 2 inch welded wire mesh 【1 2 inch welded wire mesh】

Read MoreThe cage should be strong so that the bars cannot be bent or damaged by the parrot, and weak bars can be bent or damaged by the parrot and injure the parrot. Cages made of plastic coated railings can cause parrots to eat the coating and are not suitable. Quality cages are made of stainless steel, especially those made of colorful mild steel railings. Railing spacing is very important for the parrot’s safety, and the railing should always be small enough to prevent the parrot from poking its head out between the railing gaps. For small parrot species, column spacing of 1/2 inch (1.3 cm) is necessary. Medium parrot species such as grey parrots and Amazons require a 1 inch (2.5 cm) pitch, while great macaws can reach a pitch of more than 1 by inch (3.8 cm).

1 2 inch welded wire mesh...

1 2 inch welded wire mesh 【1 2 inch welded wire mesh】

Read More1 2 inch welded wire mesh

...

1 2 inch welded wire mesh 【1 2 inch welded wire mesh】

Read More

1 2 inch welded wire meshBenefits of using a pet cage:

...

1 2 inch welded wire mesh 【1 2 inch welded wire mesh】

Read More1 2 inch welded wire mesh

...

1 2 inch welded wire mesh 【1 2 inch welded wire mesh】

Read More

1 2 inch welded wire meshSmall and medium-sized cat cage, dog cage and fence are mostly pure wire welding, wire diameter is generally between 2-5mm. Of course, the larger the cage, the thicker the wire, because the larger cage has to withstand more force.

...

1 2 inch welded wire mesh 【1 2 inch welded wire mesh】

Read More1 2 inch welded wire mesh

...

1 2 inch welded wire mesh 【1 2 inch welded wire mesh】

Read More

Popular articles

Regarding the placement of the cage, the top of the cage should not be higher than your standing eye level. This is because tall parrots are usually superior and not easy to tame. But for overly frightened parrots it can be slightly above your eye level. The bottom of the cage is usually equipped with a tray to prevent objects such as bird seed from falling to the ground and to prevent parrots from bumping their feet through the bars at night. The chassis should be covered with newspaper and replaced daily. To help the parrot feel safer, the cage should have a solid side and not be surrounded by bars. If a solid side is hard to find, put one side of the cage against a solid wall.

- In cow pen net there are generally pvc covered plastic pvc covered plastic is in the original galvanized steel wire coated with a layer of dark green or gray brown plastic mold, to avoid the corrosion of wire diameter, conducive to the improvement of the corrosion and rust prevention function of wire diameter. So the better the material, the higher the price. Zinc-aluminum alloy cattle net is the best metal net on the market, the price is higher than hot dip galvanized raw materials. The service life is about 80-90 years, and the anti-corrosion function is excellent.

Cold galvanizing (galvanizing) is in the plating tank after the current unidirectional, so that the zinc gradually plated on the metal surface, slow production speed, uniform coating, thin thickness, usually as long as 3-15g, bright appearance, poor corrosion resistance, usually a few months will rust. Compared with hot dip galvanizing, the production cost of electric galvanizing is lower.

- Large hexagonal mesh called stone cage net, is mainly used for mountain protection, hydraulic construction and so on. Small wire hexagonal mesh is used as a good material for breeding, will twist twist hexagonal mesh in the welded iron frame on the hexagonal mesh welding into chicken coop, pigeon cage, rabbit cage cage cage, hexagonal mesh is the best material for breeding with a net.

- Although many species of parrots are native to tropical regions, birds are susceptible to heat stroke. So in warm weather, don’t put the cage directly in front of a window in direct sunlight, or in an unshaded and unventilated garden.

Latest articles

-

-

Post time: 28-02-23 -

The wide application of galvanized wire has brought great convenience to people’s production and life, but the production process of iron wire is also not to be underestimated. In industrial production, the production process of galvanized wire should be strictly controlled to ensure the quality of galvanized wire.

-

-

The production and processing process of the blade thorn rope is complicated, which requires the cooperation of all departments, and the production cycle is relatively long. Whether galvanized rope or stainless steel rope, because of the relatively simple structure, the degree of mechanization in the production process is relatively high, so it is also a relatively big difference in price.

-

Links

- The primary function of floor demarcation tape is to create visual cues that guide human behavior. In industrial settings, it is used to demarcate designated areas such as walkways, machinery zones, and emergency exits, thereby preventing accidental forays into hazardous regions. For instance, the familiar yellow tape signifies caution, alerting workers to potential dangers, while green tape often denotes safe pathways or environmental zones.

2. Durability Red insulation tape is designed to withstand high temperatures and resist various environmental factors. This durability ensures that it can maintain its insulating properties over time, even in challenging conditions.

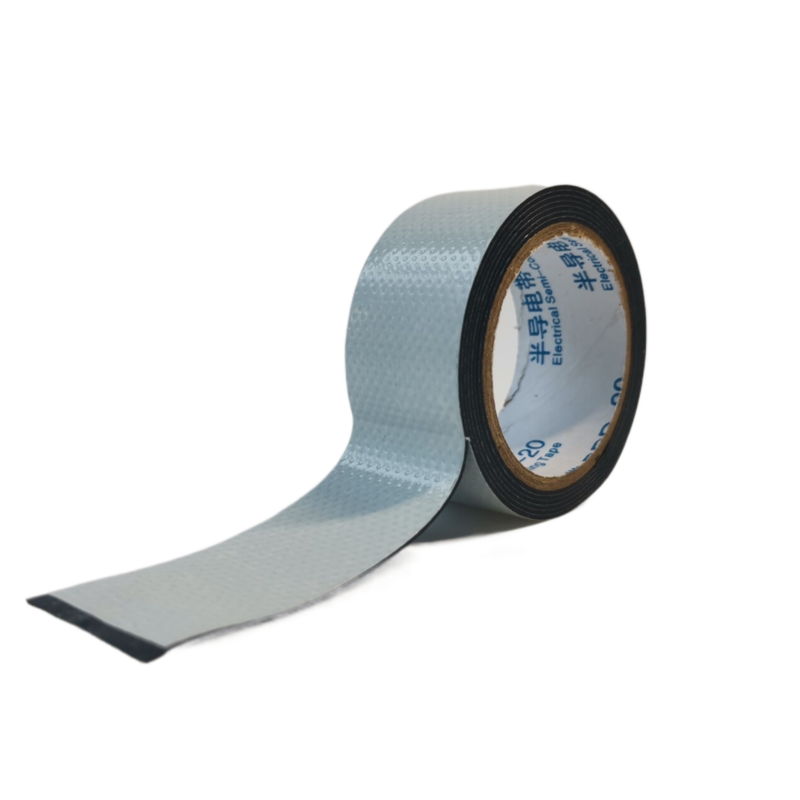

Butyl Rubber Tape

Tips and Tricks

Bundle cables to keep them tidy

One of the significant advantages of using fireproof gasket tape is its versatility. It can be employed in various applications, including but not limited to sealing joints in HVAC systems, creating airtight seals in exhaust systems, and providing insulation in electrical enclosures. The tape can also be used in industries dealing with flammable materials, where it plays a crucial role in enhancing the safety of the work environment.

Our buyer’s guide will tell you everything you need to know about this handy tape.

Key Benefits of Red Insulation Tape

we supply self-amalgamating tape manufactured from ethylene propylene rubber which is weatherproof and rugged enough to cope with the demands of most applications, including roofing and sailing where it is used as rigging tape. There are silicone self-amalgamating tapes which offer a slightly higher voltage rating than ethylene propylene rubber but these offer much poorer tear resistance.

The applications of black PVC electrical tape are numerous. One of its primary functions is insulation. Electricians use it to wrap exposed wires and connections, helping to prevent short circuits and protect against electrical shocks. Its high dielectric strength ensures that it can handle the demands of various voltage levels, making it a reliable choice for residential, commercial, and industrial settings.

Aerospace:The aerospace industry also takes advantage of the properties of butyl sealant tape by using it to seal joints, seams, and gaps in aircraft components.

Electrical Applications

This makes it perfect for applications where stability and longevity are paramount This makes it perfect for applications where stability and longevity are paramount

This makes it perfect for applications where stability and longevity are paramount This makes it perfect for applications where stability and longevity are paramount seal it silicone insulation tape.

seal it silicone insulation tape.

gymnasium floor tape. This tape can be easily applied and removed, allowing sports facilities to quickly and easily alter playing areas or designate new boundaries as needed. This flexibility is especially important in multi-sport facilities, where different sports may require different playing areas or boundary lines.