3 4 sheetrock screws

Latest articles

3 4 sheetrock screws

Post time: 14-06-24...

3 4 sheetrock screws 【3 4 sheetrock screws】

Read More3 4 sheetrock screws

...

3 4 sheetrock screws 【3 4 sheetrock screws】

Read More

3 4 sheetrock screwsIn the process of composite electroplating galvanized wire, the plating solution must be stirred to obtain the composite coating in which the particles dispersed in the matrix metal. Stirring methods include mechanical stirring, air stirring, ultrasonic stirring, bath circulation, etc. The acid activation solution in the production process can remove the corrosion products and oxide film on the surface of the low carbon steel wire without excessive corrosion on the matrix.

...

3 4 sheetrock screws 【3 4 sheetrock screws】

Read More3 4 sheetrock screws

...

3 4 sheetrock screws 【3 4 sheetrock screws】

Read More2, PVC coated barbed rope has strong corrosion and turbidity resistance

3 4 sheetrock screws...

3 4 sheetrock screws 【3 4 sheetrock screws】

Read MoreAnd the air humidity is large, continuous rainy weather, or the environment with large acidity in the air is easy to rust. 304 stainless steel material, if the surrounding environment is too poor will rust.

3 4 sheetrock screws...

3 4 sheetrock screws 【3 4 sheetrock screws】

Read More

3 4 sheetrock screwsThe hot plating wire is made of low carbon steel wire rod, which is processed by drawing forming, pickling and rust removal, high temperature annealing, hot dip galvanizing and cooling. Galvanized iron wire has resistance and elasticity, the amount of zinc can reach 300 g/square meter, with thick galvanized layer, strong corrosion resistance and other characteristics. Widely used in construction, handicrafts, wire mesh, highway guardrail, commodity packaging and ordinary civilian and other fields.

...

3 4 sheetrock screws 【3 4 sheetrock screws】

Read MoreWire diameter: 6#–20#, this kind of barbed wire is braided by low carbon steel wire; Aperture: 15′-15′ special standards can be processed according to customer needs. Use: to be used for road beautification with protective net, maintenance and support of seawall, hillside, dam embankment, is a good data to avoid landslides.

3 4 sheetrock screws...

3 4 sheetrock screws 【3 4 sheetrock screws】

Read More3 4 sheetrock screws

...

3 4 sheetrock screws 【3 4 sheetrock screws】

Read More

3 4 sheetrock screws

Post time: 06-01-23...

3 4 sheetrock screws 【3 4 sheetrock screws】

Read More

Popular articles

Stainless steel blade barbed wire production process is similar to galvanized blade barbed wire production process, usually according to the mold to determine the size of the blade.

Welding mesh is also known as external wall insulation wire mesh, galvanized wire mesh, galvanized welding mesh, wire mesh, row welding mesh, touch welding mesh, construction mesh, external wall insulation mesh, decorative mesh, barbed wire, square eye mesh, screen mesh, anti-crack mesh. Stainless steel welding net, is made of high quality stainless steel wire row welding, more acid resistance, alkali resistance, solid welding, beautiful, wide use and so on.

Post time: 15-08-22- Electrode structure: portable non – electrode, including cylinder, tube, sleeve plug. Explosive welding flux by high fever agent and additives such as metal or metal oxide powder forming technology; Commonly used medicine tube paper tube. It can also be used for different weldment and use environment, use metal pipe, etc; Plug at the end of the electrode, which is with casing welding clamping position of the match, and stop welding flux leakage from the tube.

Latest articles

-

The different spacing of the thorn rope is mainly in order to save costs to consider, because if they are too close, then obviously a little waste of resources, but the installation is too sparse will not work. Usually the bottom spacing is about 10cm, and the top is up to 20cm, this is because the higher the place is more difficult to climb over, usually more than one meter without the help of tools it is difficult for ordinary people to climb over, and the bottom because of the relatively tight can prevent personnel from drilling in the past.

-

-

Post time: 11-06-24 -

-

1. High tensile strength and durability

-

2, pasture installation of thorn rope spacing, if it is cattle or horses due to the larger size, the spacing can be appropriately relaxed. But if it’s a sheep, it’s a smaller animal and you have to make it a little bit narrower.

Links

- Medical.

- However, it's important to note that not all fire-resistant foam tapes are created equal. The choice of tape depends on the specific application and the level of fire resistance required. Therefore, it's crucial to consult with experts and choose a product that meets industry standards and certifications.

Repair damaged seals in steam cleaners

- - **Clean the Surface** Before applying floor line marking tape, make sure to clean the floor surface to remove any dust or debris that could interfere with the adhesion of the tape Best Practices for Using Floor Line Marking Tape

Quality Assurance: certifications and quality standards ensure that you're investing in a reliable and effective product.

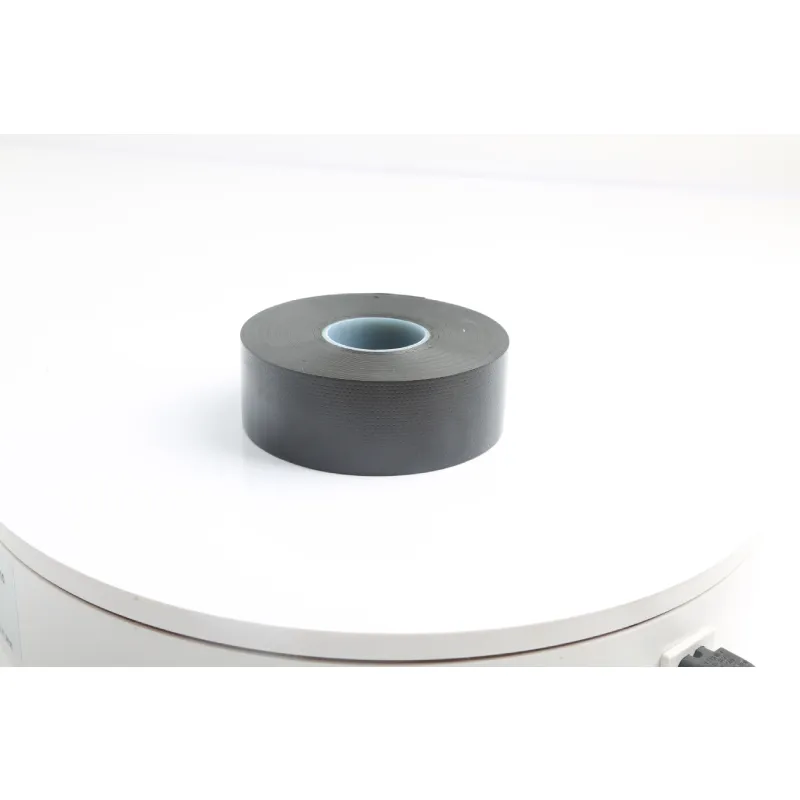

Self-fusing rubber tape is a simple yet powerful solution that addresses various repair and maintenance needs. Its unique properties, including self-adhesion, flexibility, resistance to extreme temperatures, and waterproofing capabilities, make it an indispensable resource for both professionals and DIY enthusiasts. Whether you are looking to fix a leaky pipe, insulate electrical wires, or bundle tools, self-fusing rubber tape offers an efficient and reliable option that stands the test of time. With its growing popularity, this remarkable tape is poised to become a staple in households and industries alike, proving that sometimes the simplest solutions can provide the most significant benefits.

In addition to its electrical uses, this tape proves invaluable for plumbing and HVAC applications, where it can seal leaks and provide thermal insulation. DIY enthusiasts also appreciate its versatility for home repairs, crafts, and even outdoor projects.

RUBBER

This means that it can withstand exposure to moisture without losing its adhesion, making it an excellent choice for outdoor projects or situations where moisture may be present This means that it can withstand exposure to moisture without losing its adhesion, making it an excellent choice for outdoor projects or situations where moisture may be present

This means that it can withstand exposure to moisture without losing its adhesion, making it an excellent choice for outdoor projects or situations where moisture may be present This means that it can withstand exposure to moisture without losing its adhesion, making it an excellent choice for outdoor projects or situations where moisture may be present flex tape mini black. Whether you're working in the garden or repairing a leaky roof, Flex Tape Mini Black will keep your project secure.

flex tape mini black. Whether you're working in the garden or repairing a leaky roof, Flex Tape Mini Black will keep your project secure.As with any adhesive, there are actions to ensure your project is adequately covered and protected. To properly install butyl tape, follow these simple steps.

At its core, insulation tape is designed to insulate electrical wires and other conductive materials. The 50mm width makes it especially suited for larger cables and applications where broader coverage is necessary. Typically made from a blend of PVC and rubber, black insulation tape is favored for its durability and resistance to electric current, heat, and moisture. The black color also provides a sleek look that blends well with many surfaces, making it ideal for both visible and hidden applications.

When properly applied, quality tapes can serve as valuable standby resources for jobs such as insulating motor lead connections, inline splices, and split bolt and bus bar connections. Let's take a look at some guidelines for each.