different types of wire mesh

Latest articles

different types of wire meshThe external environment has a great influence on the storage of cold drawn wire. Especially during the rainy season, special attention should be paid to the air humidity of workshops and warehouses. It is recommended to use moisture test paper with a value between 8 and 10. If the PH value is high, attention should be paid to the corrosion of the internal cold drawing wire. Cold drawing wire in normal environment storage for two years no problem, cold drawing wire will not be corroded. However, it is necessary to place the coil gently during the handling process to avoid the winding position leading to the cable is not smooth.

...

different types of wire mesh 【different types of wire mesh】

Read MoreThis material itself has the advantages of good integrity, uniform force, high strength, wear resistance, corrosion resistance and so on. Moreover, the production process is simple and the degree of industrialization is high, so its economic benefits are better than other metal mesh materials. In some industrially developed countries, this material has long been used in urban and rural roads, tarmac runway is also widely used. The application of galvanized wire welding net in the construction industry is countless, and the application of galvanized wire welding net in the construction industry has been greatly developed.

different types of wire mesh...

different types of wire mesh 【different types of wire mesh】

Read Moredifferent types of wire mesh

...

different types of wire mesh 【different types of wire mesh】

Read More

different types of wire mesh

Post time: 09-09-22...

different types of wire mesh 【different types of wire mesh】

Read More

different types of wire mesh

Post time: 14-11-22...

different types of wire mesh 【different types of wire mesh】

Read Moredifferent types of wire mesh

...

different types of wire mesh 【different types of wire mesh】

Read More

different types of wire mesh

Post time: 24-06-22...

different types of wire mesh 【different types of wire mesh】

Read Moredifferent types of wire mesh

...

different types of wire mesh 【different types of wire mesh】

Read Moredifferent types of wire mesh

...

different types of wire mesh 【different types of wire mesh】

Read More

different types of wire mesh

Post time: 08-06-22...

different types of wire mesh 【different types of wire mesh】

Read More

Popular articles

Galvanized wire mesh is divided into hot dip galvanized wire mesh and cold galvanized wire mesh. Galvanized steel wire net selects the high quality low carbon steel wire, iron wire factory made by precision of automation machinery welding technology processing, smooth surface, firm structure, integrity is strong, even if the local cutting of galvanized steel wire net, or local also under pressure from loose phenomenon, after molding, wire mesh galvanized corrosion resistance good, has the advantage that the general steel mesh does not have.

- The diameter of welded mesh wire for external walls is generally 2.2-ф4.0, and the mesh is generally 25-50.

- 2. Take out the items in the cage. First, rinse most of the dirt off the cage with water, and then wipe the dirt around it with a wet towel; And then clean the cage.

Latest articles

-

Large roll galvanized wire phosphating film is dark gray to black gray, the thickness is generally 5-20μm, has better corrosion resistance in the atmosphere. Membrane is a microporous structure, strong adsorption ability to paint, such as used as paint bottom, corrosion resistance can be further advanced. Metal oxidation treatment: Add steel products to NaOH and NaNO2 mixed solution, heating treatment, the surface can form a layer of thickness of about 0.5-1.5μm blue oxide film, in order to reach the purpose of steel corrosion prevention, this process is called blue treatment, referred to as blue.

-

-

Post time: 17-05-22 -

-

-

3. Quality test report

Links

Charcoal firing is used to create wrought iron fences. According to the Real Wrought Iron Company, a supplier of genuine wrought iron, it can also be produced as a by product of cast iron production.

Wrought iron rail parts have long been a staple in the construction industry, known for their durability, strength, and timeless beauty. These components are essential for creating railings that provide both safety and aesthetic appeal in homes, commercial buildings, and public spaces.

Railings, too, benefit from the beauty of ornamental wrought iron. Whether used on staircases, balconies, or patios, these railings can be designed to reflect a range of architectural styles, from classic to contemporary. The intricate balusters and handrails can be crafted to match the surrounding decor, creating a seamless integration that elevates the overall aesthetic of a space. Furthermore, the durability of wrought iron ensures that these installations withstand the test of time, making them a wise investment for homeowners and businesses alike.

ornamental wrought iron

Design Versatility

In conclusion, understanding the various parts of wrought iron fences is crucial for homeowners considering this elegant option for their property. Each component—posts, rails, pickets, gates, finials, finishes, and accessories—contributes to the overall functionality, security, and beauty of the fence. By choosing the right combination of materials and designs, homeowners can create a stunning wrought iron fence that not only meets their practical needs but also enhances the overall curb appeal of their property. This investment in quality fencing can last for decades, making it a wise and stylish choice for any property owner.

Practical Advantages

Another advantage of sliding cabinet rollers is their ease of use. With just a gentle push or pull, the shelves slide in and out smoothly, allowing you to easily access items without any hassle. This can be particularly helpful for individuals with limited mobility or strength, as it eliminates the need to reach or bend to retrieve items from the back of the cabinet. Additionally, the smooth sliding motion of the rollers helps protect delicate items from being jostled or knocked over, ensuring that your cabinet contents remain safe and secure.

Therefore, for internal use, it’s worth considering specialist internal window products with brands.

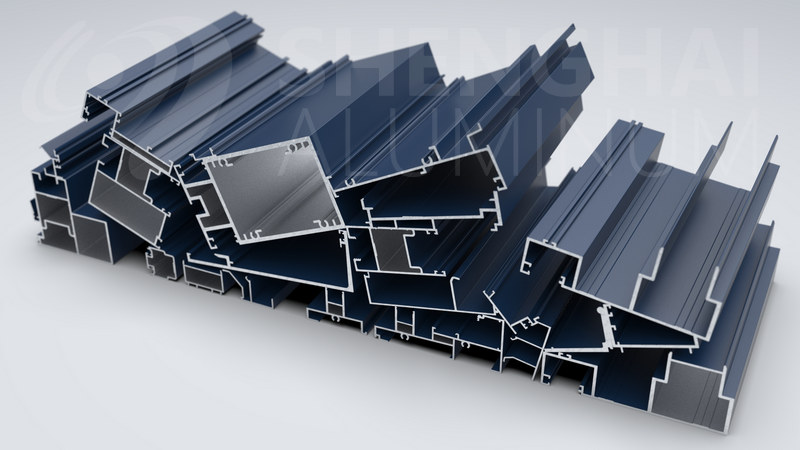

Aluminum profiles require very few maintenance compared to other materials. There is no need for regular painting or treatment, and standard cleaning agents can be used for cleaning and maintenance.