1 inch x 1 inch wire mesh

Latest articles

1 inch x 1 inch wire mesh

...

1 inch x 1 inch wire mesh 【1 inch x 1 inch wire mesh】

Read MoreFirst of all, the protective layer of zinc-iron alloy can prevent the steel wire from being corroded by oxidation. The zinc metal reacts with water and oxygen to form a dense zinc oxide layer, which forms a physical barrier to prevent oxygen and water from entering the inside of the steel wire, reducing the chance of corrosion. Compared with ordinary steel wire, hot-dip galvanized wire is more resistant to corrosion in humid, high humidity or corrosive environments such as acid and alkali, so it is more durable.

1 inch x 1 inch wire mesh...

1 inch x 1 inch wire mesh 【1 inch x 1 inch wire mesh】

Read More

1 inch x 1 inch wire mesh...

1 inch x 1 inch wire mesh 【1 inch x 1 inch wire mesh】

Read More1 inch x 1 inch wire mesh

...

1 inch x 1 inch wire mesh 【1 inch x 1 inch wire mesh】

Read More1 inch x 1 inch wire mesh

...

1 inch x 1 inch wire mesh 【1 inch x 1 inch wire mesh】

Read More1 inch x 1 inch wire mesh

...

1 inch x 1 inch wire mesh 【1 inch x 1 inch wire mesh】

Read More1 inch x 1 inch wire mesh

...

1 inch x 1 inch wire mesh 【1 inch x 1 inch wire mesh】

Read More

1 inch x 1 inch wire meshWhen galvanized wire is galvanized, it is generally necessary to pay attention to the following problems: the duration of the protective effect of galvanized wire is greatly related to the thickness of the coating. Generally speaking, in the dry main gas and in indoor use, the thickness of galvanized wire galvanized layer only 6-12 μm “, and in harsh environmental conditions, galvanized wire galvanized layer thickness needs 20μm “to B height up to 50μm”. Therefore, the environmental impact should be considered when choosing the thickness of galvanized layer. Galvanized wire in galvanized, pay attention to the above problems, can be well galvanized, to ensure the quality of galvanized wire.

...

1 inch x 1 inch wire mesh 【1 inch x 1 inch wire mesh】

Read More

1 inch x 1 inch wire meshIn reinforced concrete structure, the crack width of cold wire drawing is smaller than that of circular steel bar or even that of hot rolled thread bar. So cold wire drawing is more popular in the construction industry. The material for cold drawing is made of steel bars and can be simply explained how it is made, that is, its production process is simple. It’s based on steel bars, which are constantly stretched evenly, stretching the bars into something very thin, like wire drawing, without plasticity.

...

1 inch x 1 inch wire mesh 【1 inch x 1 inch wire mesh】

Read More

1 inch x 1 inch wire mesh

Post time: 23-08-22...

1 inch x 1 inch wire mesh 【1 inch x 1 inch wire mesh】

Read More

Popular articles

Post time: 20-10-22Dog cage mainly by welding, spraying, injection molding, surface treatment, electroplating dog cage is made of high quality steel wire, dog cages are with plastic and plastic surface treatment, electrophoresis, chrome plating, galvanized, imitation gold, etc., according to the customer request processing, respectively, also can be customized to sample, dog cage assembly of compact structure, neat and beautiful appearance, make folding and remove the cage is more convenient and quick, won’t take up too much space.

Post time: 26-04-23Broken wire is the iron bright wire, fire wire, galvanized wire, plastic coated wire, paint wire and other metal wire, wire factory according to customer requirements for straightening after sizing cut, has the characteristics of easy transportation, easy to use, widely used in the construction industry, handicrafts, daily civilian and other fields. No limit on length, packing as required. Annealing wire also known as black oiled wire, black annealing wire, fire wire, black iron wire. Compared with cold drawing, black annealed wire is more economical as raw material for nails.

Latest articles

-

1. Zinc layer thickness: under normal circumstances, the thicker the zinc layer, the better the corrosion resistance of electrogalvanized wire. This is because the increase in the thickness of the zinc layer can improve the self-corrosion performance of the zinc layer and form a better protective layer.

-

-

One is to do a good job of galvanized wire packaging, avoid bumping, to ensure the integrity of the zinc layer;

-

The wire used for barbed wire is woven or welded with low carbon steel wire, medium carbon steel wire, high carbon steel wire, stainless steel wire and other materials. The production process includes: general braid, embossed braid and spot welding. If the material is steel wire, after equipment processing into a network, it is called wire mesh.

-

Breeding cattle and sheep with barbed rope effect is better, because the advantages of more barbed rope. So is the thorn rope used to do animal husbandry good?

-

Links

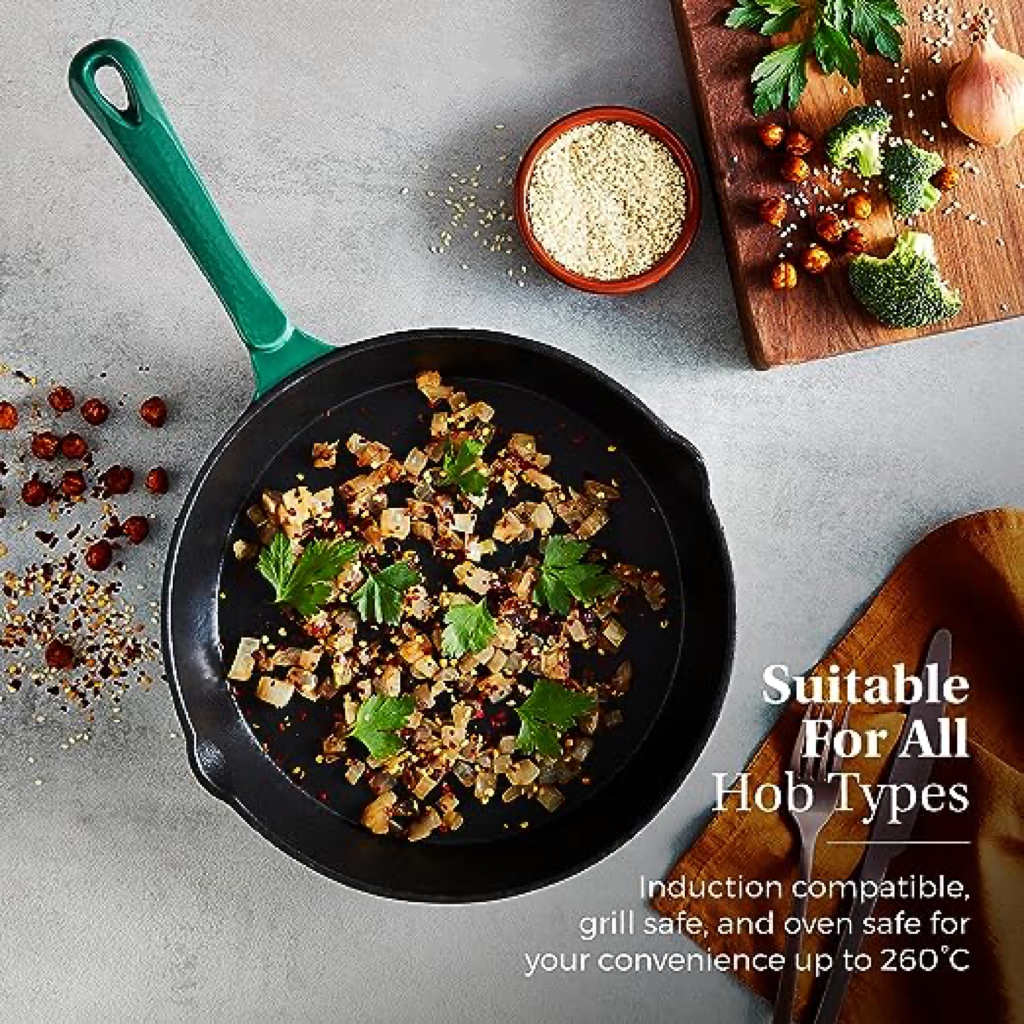

- Iron skillets have been a staple in kitchens for centuries, offering unparalleled heat retention and distribution, versatility, and durability. These pans, with their classic appeal and practical functionality, continue to captivate home cooks and professional chefs alike. If you're in the market for an iron skillet, there are several factors to consider when making your choice.

Frypan Ironically, a skillet is actually far superior at sautéing food than a sauté pan. To properly sauté, small to medium-sized pieces of food are cooked rapidly in hot fat, with constant agitation. The sloping sides of a skillet allow you to easily shake the pan, performing the jump-flip maneuver that cooks like to show off with. It's more than just ego-padding, though. It's the most efficient way to redistribute the food in the pan, ensuring even cooking for all pieces.

A frying pan is the best nonstick cookware for quickly heating up. An oven-safe skillet is a great option if you like thicker and deeper cooking tools.

Versatility and Culinary Capabilities:

:max_bytes(150000):strip_icc():format(webp)/Misen-Stainless-Steel-Frying-Pan-7c45b47235814e9daa1e0227393d729a.jpg)

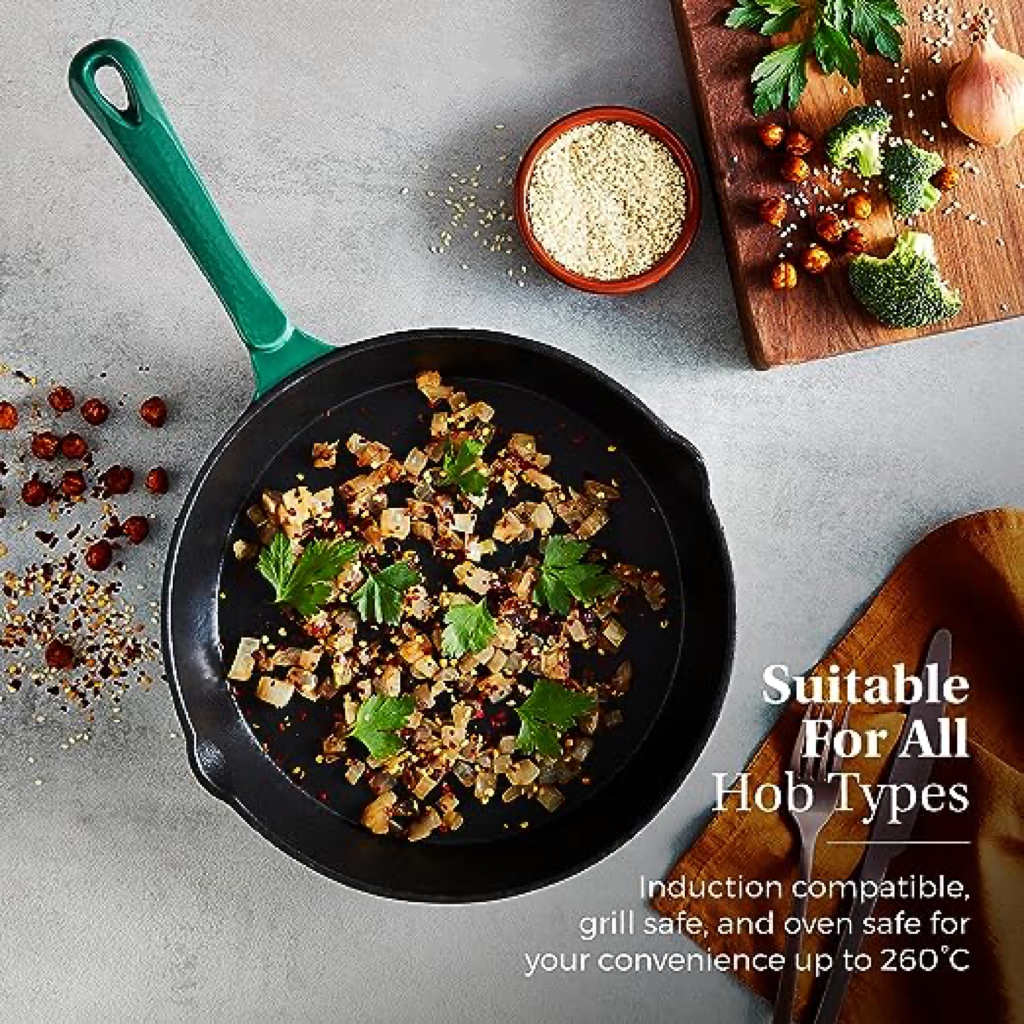

Most stainless steel pans are oven-safe. However, the max oven-safe temperature may vary by manufacturer and product line, so it is necessary to check your item's specification sheet before use.

Cast iron cooking griddles are versatile and essential tools for any kitchen, whether used in a commercial setting or at home. When it comes to Cast iron cooking griddles, there are a variety of options to choose from, including indoor cast iron griddles, commercial cast iron griddles, and custom cast iron griddles. Each type of Cast iron cooking griddle has its own unique features and benefits to suit different cooking needs and preferences.

ALUMINUM FRYING PANS

Dutch Oven Material

They can be used on both gas and electric stoves, and they can accommodate a variety of cooking techniques They can be used on both gas and electric stoves, and they can accommodate a variety of cooking techniques

They can be used on both gas and electric stoves, and they can accommodate a variety of cooking techniques They can be used on both gas and electric stoves, and they can accommodate a variety of cooking techniques enamel coated cast iron griddle. You can use them to cook breakfast favorites like pancakes, eggs, and bacon, or you can use them to prepare lunch or dinner dishes such as stir-fries, steaks, and vegetables. The possibilities are endless!

enamel coated cast iron griddle. You can use them to cook breakfast favorites like pancakes, eggs, and bacon, or you can use them to prepare lunch or dinner dishes such as stir-fries, steaks, and vegetables. The possibilities are endless!

I can quite comfortably fit 12 pieces of chicken in a 12-inch sauté pan—a task that takes two batches with a skillet.

They are designed with a flat base to ensure excellent heat transfer and a larger surface area for faster and more simultaneous cooking.

When it comes to maintenance, cast iron double griddles require minimal effort. Regular seasoning and proper cleaning will keep your cookware in tip-top shape. With its sturdy construction and low maintenance, cast iron double griddles are undoubtedly a favorite among home cooks and professional chefs alike.

From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style

From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style enamel cook set. The enamel coating not only adds aesthetic appeal but also makes the cookware easy to clean, as it is generally dishwasher-safe.

enamel cook set. The enamel coating not only adds aesthetic appeal but also makes the cookware easy to clean, as it is generally dishwasher-safe.