double door wire dog crate

Latest articles

The galvanized requirements of the parts to be plated: the surface of the parts to be plated should be smooth, and there is no dirt that cannot be removed by pickling method. Such as paint, grease, cement, asphalt and excessive rotten harmful substances; All welds of welded components shall be sealed without air; Pipe fittings and containers must have exhaust and zinc inlet holes; The workpiece should be finished welded steel pipe without thread, if any thread should be protected.

double door wire dog crate...

double door wire dog crate 【double door wire dog crate】

Read Moredouble door wire dog crate

...

double door wire dog crate 【double door wire dog crate】

Read More

double door wire dog crate

Post time: 14-07-22...

double door wire dog crate 【double door wire dog crate】

Read Moredouble door wire dog crate

...

double door wire dog crate 【double door wire dog crate】

Read Moredouble door wire dog crate

...

double door wire dog crate 【double door wire dog crate】

Read Moredouble door wire dog crate

...

double door wire dog crate 【double door wire dog crate】

Read More

double door wire dog crateThe iron is clean and clean, and then solvent treatment, after drying immersed in zinc liquid, iron and molten zinc reaction to produce an alloyed zinc layer, the process is: degreasing – washing – pickling – assisted plating – drying – hot dip galvanizing – separation – cooling passivation. The thickness of the alloy layer of hot plating wire mainly depends on the chemical composition of the steel silicon content, the size of the steel cross-sectional area, the roughness of the steel surface, the temperature of the zinc pot, the time of dipping zinc, cooling speed, cold rolling deformation, etc.

...

double door wire dog crate 【double door wire dog crate】

Read More

double door wire dog crate

Post time: 30-06-22...

double door wire dog crate 【double door wire dog crate】

Read More

double door wire dog crate

Post time: 31-05-23...

double door wire dog crate 【double door wire dog crate】

Read Moredouble door wire dog crate

...

double door wire dog crate 【double door wire dog crate】

Read More

Popular articles

- 3, barbed rope protection net in the bridge, channel, should be toward the bridge head cone slope (or end wall) direction surrounded, should not leave for people, livestock can drill into the gap.

First, galvanizing can enhance the corrosion resistance of the product. Zinc has high potential and excellent anodic protection. When the surface of the product is galvanized, zinc will have an electrochemical reaction with oxygen and water in the environment, thereby forming a dense zinc oxide protective film, preventing the metal from further contact with external oxygen, water and other substances, slowing the corrosion rate of the metal. Galvanized products after wire drawing processing, because the surface of the product has a more dense zinc oxide protective film, it can better resist external corrosion and improve the corrosion resistance of the product.

Post time: 06-05-22

Latest articles

-

-

-

Most of the production enterprises or large public places, they can play a defense hook mesh in the choice of time, often will hook mesh quality in position, so galvanized hook mesh this product few people are interested in, but does this show that galvanized hook mesh is not useful?

-

-

1, must often clean and scrub the stainless steel pet cage, keep the surface of the stainless steel pet cage clean, dry, can ensure the stainless steel pet cage bright every day.

-

Six: The characteristics of spray blade barbed rope are mechanical strength, adhesion, corrosion resistance, aging resistance, etc., which will greatly increase the service life of the barbed rope, anti-ultraviolet, anti-aging weathering.

Links

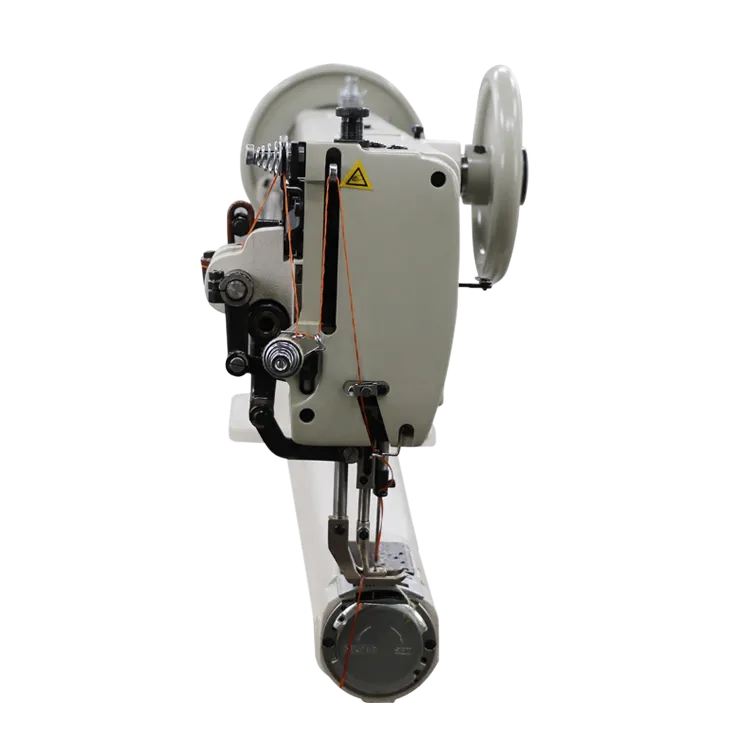

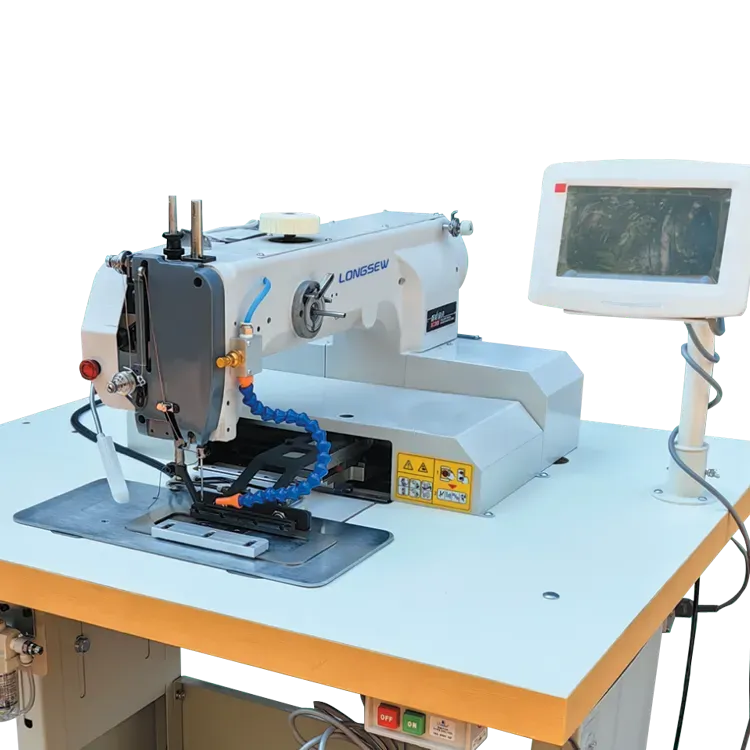

When you use a heavy duty industrial walking foot sewing machine- it comes with a built-in walking foot mechanism. This is very different that most walking foot attachments that only snap-on regular household sewing machines.

The benefits of these machines extend beyond simply threading the needle. They encourage creativity by making sewing more accessible. Many individuals who may have been intimidated by previous challenges are now able to dive into their craft with enthusiasm. This surge in confidence can lead to the production of diverse projects, from simple altercations to intricate quilts.

One of the most popular uses of twin needle sewing is for hemming garments, especially knit fabrics. Traditional sewing methods can leave seams looking unprofessional, particularly on stretchy materials, which can lead to unwanted puckering. The twin needle allows for two parallel lines of stitching, creating a professional-looking hem that retains the fabric's stretchability. This technique is particularly useful for T-shirts, leggings, and other types of activewear where elasticity is essential.

What is a Double Needle Sewing Machine?