It ensures that the information stays intact and legible throughout the product's lifecycle It ensures that the information stays intact and legible throughout the product's lifecycle

It ensures that the information stays intact and legible throughout the product's lifecycle It ensures that the information stays intact and legible throughout the product's lifecycle zebra marking tape.

zebra marking tape. It can also protect wires from mechanical damage, like abrasion or chafing, during installation or in harsh operating conditions It can also protect wires from mechanical damage, like abrasion or chafing, during installation or in harsh operating conditions

It can also protect wires from mechanical damage, like abrasion or chafing, during installation or in harsh operating conditions It can also protect wires from mechanical damage, like abrasion or chafing, during installation or in harsh operating conditions electrical pvc insulation tape. Moreover, it's a cost-effective solution compared to other insulation methods, contributing to its widespread use.

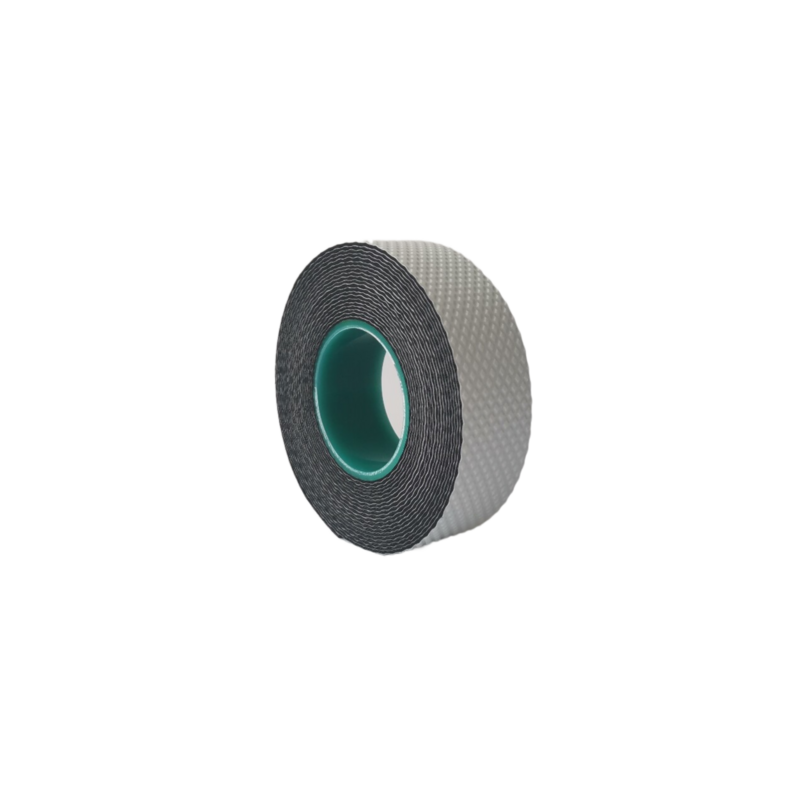

electrical pvc insulation tape. Moreover, it's a cost-effective solution compared to other insulation methods, contributing to its widespread use.One of the most significant advantages of self-fusing rubber tape is its remarkable flexibility. It can be stretched and molded to fit a wide array of shapes and surfaces, making it ideal for bundling wires, sealing leaks, and wrapping hoses. Additionally, it retains its elasticity over time, allowing it to accommodate movement without breaking or peeling away.

Silicone adhesives have the following general characteristics:

Similar to silicone rubber tape, rubber repair tape is constructed with high-quality materials to ensure safety and reliability. The manufacturing process is held to the same high standards, allowing for product customization and printing options to meet specific needs.

butyl rubber tape supplier. Scapa Group Specializing in adhesive solutions, Scapa offers custom-made butyl rubber tapes that cater to specific customer requirements. Their tapes are widely used in the solar, automotive, and construction sectors.

butyl rubber tape supplier. Scapa Group Specializing in adhesive solutions, Scapa offers custom-made butyl rubber tapes that cater to specific customer requirements. Their tapes are widely used in the solar, automotive, and construction sectors. For instance, yellow often signifies caution, while green indicates safety routes or first aid stations For instance, yellow often signifies caution, while green indicates safety routes or first aid stations

For instance, yellow often signifies caution, while green indicates safety routes or first aid stations For instance, yellow often signifies caution, while green indicates safety routes or first aid stations reflective floor marking tape. Reflective floor marking tape, therefore, not only enhances safety but also improves workplace aesthetics and order.

reflective floor marking tape. Reflective floor marking tape, therefore, not only enhances safety but also improves workplace aesthetics and order.We all know that electrical tape is an important part of any electrical job. But what many people don’t know is what temperature does electrical tape melt?

As a result, rubber splicing tape became an essential component in the production of electrical cables, hoses, and other flexible systems As a result, rubber splicing tape became an essential component in the production of electrical cables, hoses, and other flexible systems

As a result, rubber splicing tape became an essential component in the production of electrical cables, hoses, and other flexible systems As a result, rubber splicing tape became an essential component in the production of electrical cables, hoses, and other flexible systems