bug screen mesh

Latest articles

bug screen meshSteel mesh galvanized: galvanized refers to the surface of metal, alloy or other materials coated with a layer of zinc to play a beautiful, rust prevention and other surface disposal technology. Now the first choice of method is hot dip galvanized, galvanized solution has cyanide bath and cyanide-free bath two categories. Cyanide bath bisects micro cyanide, low cyanide, medium cyanide, and high cyanide.

...

bug screen mesh 【bug screen mesh】

Read Morebug screen mesh

...

bug screen mesh 【bug screen mesh】

Read Morebug screen mesh

...

bug screen mesh 【bug screen mesh】

Read Morebug screen mesh

...

bug screen mesh 【bug screen mesh】

Read More

bug screen meshEven so, when they come out, they make trouble, even though they know they will be punished, but they are only in a cage.) If you have time to refer to some foreign dog books, also strongly advocate cage training as a puppy. Before starting cage training, the cage is padded with a water bottle, some fun toys and bones to chew on. The cage door must be opened. Order the dog into the cage, then lure it into its new den with tasty cookies.

...

bug screen mesh 【bug screen mesh】

Read MoreQuality standard: Zinc content per square meter has reached or exceeded 122g.

bug screen mesh...

bug screen mesh 【bug screen mesh】

Read More

bug screen meshNow most people buy barbed rope choose blade barbed rope, why is this? The blade gill net is made of hot-dip galvanized steel plate or stainless steel sheet to punch out sharp knife sheets. The high tension galvanized steel wire or blade barbed wire is made of stainless steel wire as the core wire. Because the gill net shape is not easy to contact, so it can reach excellent protection barrier effect. The primary raw materials of the product are galvanized sheet and stainless steel plate.

...

bug screen mesh 【bug screen mesh】

Read MoreBecause of the pre-tension given to the packaging and binding of galvanized wire, it has the excellent characteristics of low relaxation value, small stress loss, good stability after loading, not easy to deformation, no fracture, strong elasticity, ordinary steel lines and rebar are difficult to compare. The use of advanced galvanized finishing process, therefore, the use of hot-dip galvanized steel wire construction, not only good corrosion resistance, but also beautiful and generous. The product has the characteristics of smooth surface, high dimensional accuracy, good uniformity of zinc layer and strong adhesion.

bug screen mesh...

bug screen mesh 【bug screen mesh】

Read More

bug screen mesh

Post time: 05-05-23...

bug screen mesh 【bug screen mesh】

Read MoreIn use, it can be well used in the annealing process to control its degree of hardness, mainly used in the construction industry for binding silk and tying. Its use is certainly not limited to arts and crafts. It is also widely used in the construction industry. Earlier woven lanterns were made of wire, and inside were placed suitable candles, which were hung in front of the door. It was very beautiful to go up at night.

bug screen mesh...

bug screen mesh 【bug screen mesh】

Read More

Popular articles

Post time: 21-09-22- 6: spray blade barbed rope is characterized by mechanical strength, adhesion, corrosion resistance, aging resistance, etc., which will greatly increase the service life of the barbed rope, uv resistance, aging resistance.

① The diameter of galvanized iron wire for drawing shall not be less than 4mm, and the diameter of galvanized iron wire for binding shall not be less than 2.6mm.

- Compared with electric galvanized iron wire, hot dip galvanized iron wire has higher zinc layer, better anti-corrosion performance, and is suitable for the more important anti-corrosion and anti-rust status.

Latest articles

-

Post time: 13-09-22 -

-

-

-

In order to pack and bundle galvanized wire on the surface of the deposit layer to remove the surface film, surface inclusion and other defects can be found and treated by conventional technology; Excess foam is caused by soaps and saponable fatty surfactants being brought into the tank. Moderate foam formation rates may be harmless. Small homogeneous particles of large denier present in the tank can stabilize the foam layer. To remove surface active substances by matting with activated carbon. Or filtration to make the foam less stable, which are effective measures; Other measures should also be taken to reduce the intake of surfactant. The electroplating speed can be significantly reduced by the introduction of organic matter. Although the chemical formula is conducive to a high deposition rate, the coating thickness cannot meet the requirements after the organic matter is loaded, so activated carbon can be used to treat the tank.

-

Post time: 27-10-22

Links

There are many criteria to consider when choosing a heavy duty sewing machine. We will start with the beginning and make it a lot easier for you.

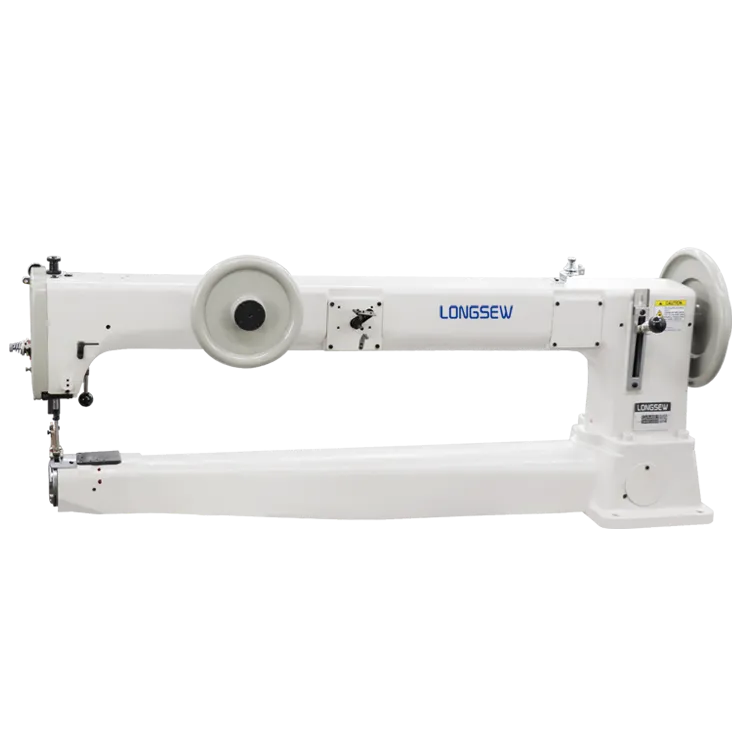

Cylinder arm sewing machines are a staple in many sewing and textile production environments due to their unique design and functionality. Understanding what a cylinder arm sewing machine is used for can help you appreciate its versatility and decide if it’s the right addition to your sewing toolkit. This article will delve into the various applications of cylinder arm sewing machines and highlight their benefits.