welded wire mesh gauge 16

Latest articles

(3) For some use of special paint spraying should be baked, of course, depending on the size of the area, small can be placed in the oven, large can only be dried first, and then to dry parts for processing, lock baking, if other circumstances can only use high temperature tools bit by bit baking. The products that can be baked in the oven should be leveled at room temperature for 15 to 30 minutes, baked at a low temperature of 60 degrees Celsius for half an hour, and then baked at the reserved baking temperature for one and a half hours, and then cooled down.

welded wire mesh gauge 16...

welded wire mesh gauge 16 【welded wire mesh gauge 16】

Read MoreUsing the patented technology of the invention, regularly put zinc block into the plating aid pool, so that the bivalent iron in the plating aid into trivalent iron, and play a stable PH value in a numerical range of an important measure, but also easy to filter out the trivalent iron ions in the plating aid; Ferric ion is controlled between 0.3 and 1.0g/L; When hydrogen is not released in the plating aid, the zinc block is continued. It is an effective measure to reduce zinc slag, improve the fluidity of zinc liquid and reduce the thickness of zinc layer to play the role of plating aid filter.

welded wire mesh gauge 16...

welded wire mesh gauge 16 【welded wire mesh gauge 16】

Read Morewelded wire mesh gauge 16

...

welded wire mesh gauge 16 【welded wire mesh gauge 16】

Read MoreNow hexagonal net is widely used in the protection of bridge, pier and bridge buttress inclined plane, there are many kinds of bridge buttress inclined plane, people choose the right hexagonal net according to the inclination of the inclined plane, when the inclined plane is gentle, people generally use gabion slope protection system, and in the case of steep slope, people will use gabion mesh gravity protection wall.

welded wire mesh gauge 16...

welded wire mesh gauge 16 【welded wire mesh gauge 16】

Read More

welded wire mesh gauge 16The protective duration of the galvanized layer of large roll galvanized wire is closely related to the thickness of the coating. Generally speaking, in relatively dry main gas and indoor use, and in harsh environmental conditions, the thickness of galvanized layer needs to be very high. Therefore, the environmental impact should be considered when choosing the thickness of galvanized layer. After passivation treatment of galvanized layer, a layer of bright old and beautiful color passivation film can be generated, which can significantly improve its protective performance.

...

welded wire mesh gauge 16 【welded wire mesh gauge 16】

Read Morewelded wire mesh gauge 16

...

welded wire mesh gauge 16 【welded wire mesh gauge 16】

Read More

welded wire mesh gauge 16

Post time: 15-02-23...

welded wire mesh gauge 16 【welded wire mesh gauge 16】

Read Morewelded wire mesh gauge 16

...

welded wire mesh gauge 16 【welded wire mesh gauge 16】

Read MoreIn the processing of stainless steel barbed wire after cold galvanized or hot galvanized coating on the surface of the last zinc material, not only beautiful but also plays a good protective role.

welded wire mesh gauge 16...

welded wire mesh gauge 16 【welded wire mesh gauge 16】

Read Morewelded wire mesh gauge 16

...

welded wire mesh gauge 16 【welded wire mesh gauge 16】

Read More

Popular articles

Most of the production enterprises or large public places, they can play a defense hook mesh in the choice of time, often will hook mesh quality in position, so galvanized hook mesh this product few people are interested in, but does this show that galvanized hook mesh is not useful?

- Zinc-coated wire is dipped in molten zinc with high production speed and thick but uneven coating. The thickness allowed by the market is 45 microns, the color is dark, the consumption of zinc metal, and the base metal to form infiltration layer, good corrosion resistance, hot dip galvanizing can be maintained for decades in the outdoor environment.

In addition, heavy hexagonal net is commonly used in water conservancy projects, as the use of loading stone box, in order to achieve the purpose of river management, floods, in addition to it can also be used as slope prevention, retaining wall, breeding and cherish animals. Small hexagonal net is usually used for animal breeding, wall protection network, green vegetation network and so on.

Galvanized wire coating is galvanized, aluminum plated, coated with nylon or plastic, etc. Zinc is divided into thin coating of steel wire after plating and thick coating of galvanized steel wire after drawing. The mechanical properties of thick coating are reduced compared with smooth steel wire rope, which should be used in severe corrosion environment. It is more resistant to corrosion, wear and heat than galvanized wire rope, using the first plating and then drawing method of production. Coated nylon or plastic wire rope is divided into two kinds of coated rope and coated stock after the rope.

Latest articles

-

Post time: 25-04-23 -

Post time: 20-09-22 -

Post time: 31-08-22 -

-

2, PVC coated barbed rope has strong corrosion and turbidity resistance

-

Pay attention to safety in line collection and operation, others without the consent of the monitor, Ben have to get on the bus operation. The reels should be placed lightly, stacked firmly and neatly, not more than 5 reels. Direct contact with acid and alkali must be prohibited. When the acid fog exceeds the specified target of the state, measures should be taken to control it in time, otherwise production is not allowed.

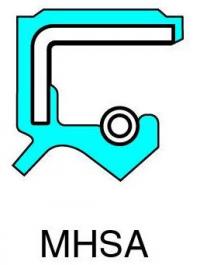

Unthinkable in the list of seals are oil seals, which provide a seal against splashing oil. The most important oil seals are used for rotating shafts and valve stem seals. Oil seals are intentionally never completely sealed to lubricate the seals and prevent wear.

oil seal 14x22x5. Enhanced Reliability The durable construction and high-quality materials used in the manufacturing of the 14x22x5 oil seal ensure long-lasting performance and reliability in harsh operating conditions.

oil seal 14x22x5. Enhanced Reliability The durable construction and high-quality materials used in the manufacturing of the 14x22x5 oil seal ensure long-lasting performance and reliability in harsh operating conditions.Car engine oil seals are essential components that prevent oil leaks and maintain proper lubrication within the engine. They play a crucial role in preserving the integrity and efficiency of the engine, contributing to its overall performance and longevity. High-quality engine oil seals are designed to withstand the demanding conditions of automotive operation, ensuring reliable sealing solutions for critical engine components.

A spring, the composition of which depends on the type

A rubber or PTFE sealing lip

Oil seals, also referred to as shaft seals, are widely used to prevent the leakage of medium (such as oils and grease) along a rotating shaft. This leak prevention is primarily achieved by the sealing element which can be made from a wide range of materials that are chosen according to each application. They are commonly used in gearboxes, hydraulic cylinders, and related components.

Maintenance and Replacement of Oil Seals

These gaskets are often made from flexible rubber compounds that can withstand the pressure and temperature variations common in plumbing applications These gaskets are often made from flexible rubber compounds that can withstand the pressure and temperature variations common in plumbing applications

These gaskets are often made from flexible rubber compounds that can withstand the pressure and temperature variations common in plumbing applications These gaskets are often made from flexible rubber compounds that can withstand the pressure and temperature variations common in plumbing applications thin rubber gasket.

thin rubber gasket.Viton (Fluorocarbon)

There are several materials used to manufacture oil seals. They are discussed below.