4x4 wire panels

Latest articles

4x4 wire panels

...

4x4 wire panels 【4x4 wire panels】

Read More

4x4 wire panelsApplication: Mainly used in communication devices, medical equipment and braided mesh, brush, steel cable, filter screen, high pressure pipe, construction, technical products and other professional electric galvanized wire: is a low carbon steel as core wire, metal composite materials processed by wire drawing, electric galvanized technology.

...

4x4 wire panels 【4x4 wire panels】

Read More

4x4 wire panels5, after the light plating should be carried out light treatment.

...

4x4 wire panels 【4x4 wire panels】

Read More4x4 wire panels

...

4x4 wire panels 【4x4 wire panels】

Read MoreBecause the barbed rope is a strong use of regeneration value. Generally, the use of discarded guardrail networks for exercise, or steel production of new structural raw materials, do a good job of daily cleaning up and recovery can promote the value of the whole guardrail network faster. Again is to recover the use, the use of it in the appearance of the use of places that are not high, such as as other days purse Seine; Taking apart or discarding the raw materials that do not need to rust can carry out the whole regeneration.

4x4 wire panels...

4x4 wire panels 【4x4 wire panels】

Read More4x4 wire panels

...

4x4 wire panels 【4x4 wire panels】

Read More

4x4 wire panels...

4x4 wire panels 【4x4 wire panels】

Read More

4x4 wire panelsWith the improvement of people’s living standards, now many families are raising some small pets, these small pets need a stable nest, pet cage has become a more important choice of people, each pet habits and living habits will choose to adapt to the cage.

...

4x4 wire panels 【4x4 wire panels】

Read More

4x4 wire panelsHigh quality galvanized wire in general, the zinc layer attached to the surface of the wire is relatively thick, so when we buy galvanized wire, as long as we look at the thickness of the zinc layer machine, we can generally judge whether the quality of galvanized wire is high quality.

...

4x4 wire panels 【4x4 wire panels】

Read More4x4 wire panels

...

4x4 wire panels 【4x4 wire panels】

Read More

Popular articles

Post time: 31-10-22Hot dip galvanizing is to remove oil from the workpiece, pickling, dipping, drying after dipping into the dissolved zinc solution for a certain time, can be brought out. Hot dip galvanizing is an effective way to prevent corrosion of metal. It is mainly used for metal structure facilities in various industries. It is to immerse the steel parts after rust removal into the melting zinc liquid at about 500℃, so that the surface of the steel members is attached with zinc layer, so as to play the purpose of anti-corrosion. The galvanized layer is more firm.

- 3. Kinks caused by uncontrolled relaxation should be avoided

Because the coastline is generally erected for protection, but often because of environmental factors lead to serious corrosion of the barbed rope lost its function. Stainless steel barbed rope is specially set up to prevent corrosion. Stainless steel barbed rope because the environmental requirements are not very high can be very good protection itself will not have a problem to extend the use of life, so that you can ensure safety.

Latest articles

-

Welding net material has black wire, galvanized wire, wire drawing. Mesh has 1 inch, 2/1 inch, 3/1 inch, 4/1 inch, 4/3 inch, 8/5 inch, etc. Different materials, different mesh, used in different places. Therefore, welding net is an indispensable building material in construction industry.

-

No matter how good the quality of hot-dip galvanized barbed rope is, it is only attached to the surface of the wire with galvanized layer, and with the cause of chemical reaction, the zinc layer on the surface will gradually lose its effect because of oxidation reaction, which is more prominent in the humid area of the environment. And because, after all, the wire will rust, so the quality of hot-dip galvanized barbed rope is certainly not up to the level of stainless steel barbed rope.

-

In use, it can be well used in the annealing process to control its degree of hardness, mainly used in the construction industry for binding silk and tying. Its use is certainly not limited to arts and crafts. It is also widely used in the construction industry. Earlier woven lanterns were made of wire, and inside were placed suitable candles, which were hung in front of the door. It was very beautiful to go up at night.

-

-

-

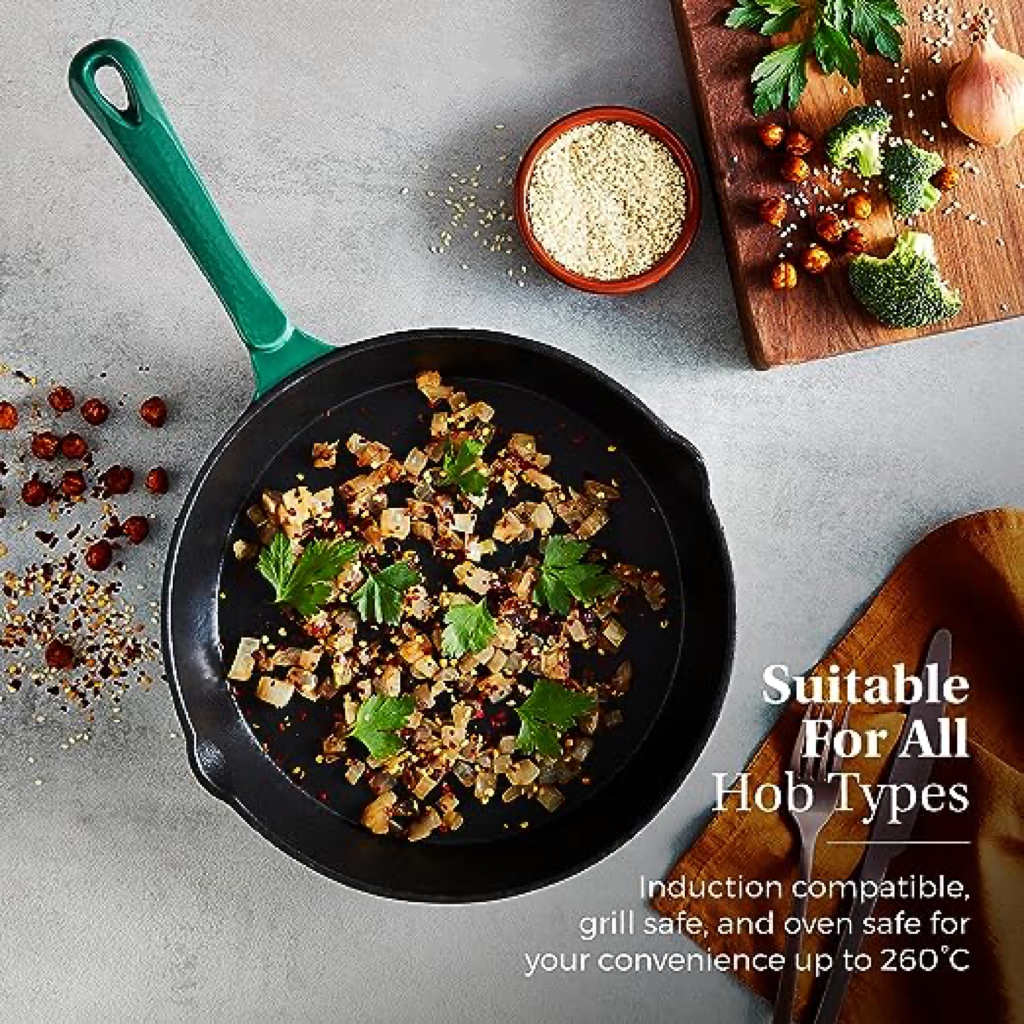

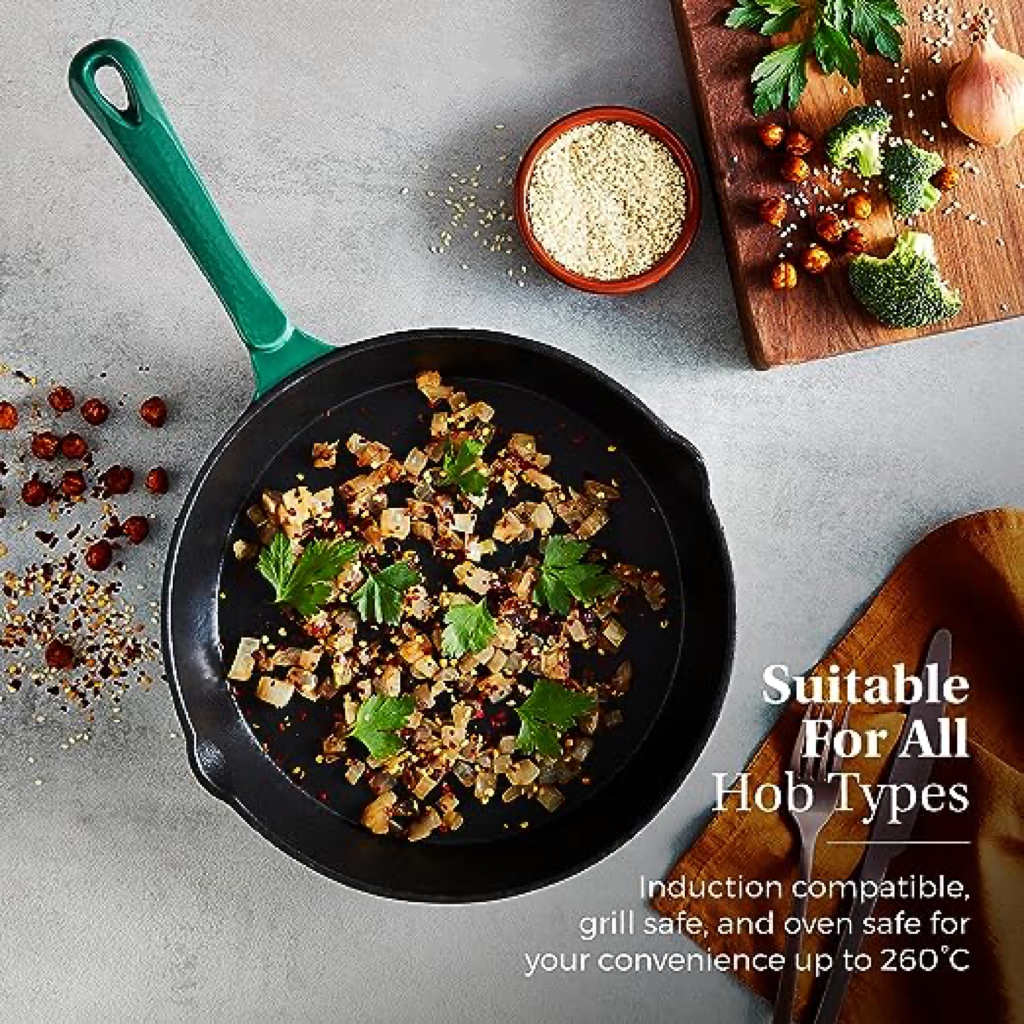

Enamel Cookware Set Advantage

How to clean: Detergents strip the seasoning. Instead, wipe clean or scrub with hot water. For stuck-on bits, rub with 1/2 cup kosher salt, then rinse.

two burner cast iron griddle. Its classic design and natural finish make it a beautiful addition to any decor, while its durability ensures that it will last for years to come.

two burner cast iron griddle. Its classic design and natural finish make it a beautiful addition to any decor, while its durability ensures that it will last for years to come.

Fry pans are specifically designed for frying and can be used to fry almost anything with less oil than deep-frying. They can also be used for other cooking methods and are versatile enough to replace other pots.

The handles are designed for comfort and stability, making it easy to handle even the heaviest pots The handles are designed for comfort and stability, making it easy to handle even the heaviest pots

The handles are designed for comfort and stability, making it easy to handle even the heaviest pots The handles are designed for comfort and stability, making it easy to handle even the heaviest pots enamel cast iron pot set.

enamel cast iron pot set.

Stainless steel

Apply this mixture to the affected areas and use a soft brush to gently scrub Apply this mixture to the affected areas and use a soft brush to gently scrub

Apply this mixture to the affected areas and use a soft brush to gently scrub Apply this mixture to the affected areas and use a soft brush to gently scrub washing cast iron grill pan. The alkaline properties of the baking soda will help break down oils and burnt pieces without harming the iron's protective layer.

washing cast iron grill pan. The alkaline properties of the baking soda will help break down oils and burnt pieces without harming the iron's protective layer.On the other hand, a frying pan can be used for far more cooking chores than a skillet. Frypans with nonstick coatings allow you to use less oil, resulting in healthier cuisine.

It requires seasoning, a process of coating the pan with oil and baking it to create a non-stick surface It requires seasoning, a process of coating the pan with oil and baking it to create a non-stick surface

It requires seasoning, a process of coating the pan with oil and baking it to create a non-stick surface It requires seasoning, a process of coating the pan with oil and baking it to create a non-stick surface cast iron outdoor grill pan. With proper care, the seasoning improves over time, enhancing the pan's non-stick properties and preventing rust.

cast iron outdoor grill pan. With proper care, the seasoning improves over time, enhancing the pan's non-stick properties and preventing rust.A French skillet is a heavy and thick saucepan usually larger, flatter, and deeper than a regular frying pan. Its size ranges from 9-11 inches, but some come in 8 or 12 inches.

While on the other side, we have the skillet which is best for cooking food at high heat such as searing, reducing, sauteing, and shallow frying. That’s because of its common construction of cast iron or stainless steel, which causes slow and even heat distribution but excellent heat retention.

This adaptability extends the scope of your outdoor cooking, letting you enjoy the sizzle and smoky flavors of the grill in any setting This adaptability extends the scope of your outdoor cooking, letting you enjoy the sizzle and smoky flavors of the grill in any setting

This adaptability extends the scope of your outdoor cooking, letting you enjoy the sizzle and smoky flavors of the grill in any setting This adaptability extends the scope of your outdoor cooking, letting you enjoy the sizzle and smoky flavors of the grill in any setting grill guru cast iron sizzling plate.

grill guru cast iron sizzling plate.A ceramic frying pan is also non-stick, but, unlike common non-stick pans which are coated with some chemical substance, ceramic pans are coated with a silica gel made from sand or ceramic stone.