stainless steel crimped wire mesh

Latest articles

Take the blade cord for example, the quality of the cord and the shape and direction of the surface barbs are what consumers need to consider.

stainless steel crimped wire mesh...

stainless steel crimped wire mesh 【stainless steel crimped wire mesh】

Read Morestainless steel crimped wire mesh

...

stainless steel crimped wire mesh 【stainless steel crimped wire mesh】

Read Morestainless steel crimped wire mesh

...

stainless steel crimped wire mesh 【stainless steel crimped wire mesh】

Read MoreThe material of wire mesh can choose galvanized wire, stainless steel wire, copper wire, coated wire, lacquer wire, etc., different materials are used in different fields, such as construction, culture, decoration, etc.

stainless steel crimped wire mesh...

stainless steel crimped wire mesh 【stainless steel crimped wire mesh】

Read More

stainless steel crimped wire mesh

Post time: 19-07-22...

stainless steel crimped wire mesh 【stainless steel crimped wire mesh】

Read Morestainless steel crimped wire mesh

...

stainless steel crimped wire mesh 【stainless steel crimped wire mesh】

Read Morestainless steel crimped wire mesh

...

stainless steel crimped wire mesh 【stainless steel crimped wire mesh】

Read MoreIn want to use barbed wire fence ground road at both ends of each set up a stake, and then from the two stakes, every 30m to set up a stake, until the installation of the line is full of stakes, so installed barbed wire net is a straight line.

stainless steel crimped wire mesh...

stainless steel crimped wire mesh 【stainless steel crimped wire mesh】

Read More

stainless steel crimped wire meshThe barbed wire factory will store the inventory of the barbed wire blade in the appropriate place because of the understanding of the product characteristics.

...

stainless steel crimped wire mesh 【stainless steel crimped wire mesh】

Read MoreRelatively speaking, the wire is relatively soft, suitable for binding. Disadvantages are low hardness, low tension, easy to stretch, not suitable for building materials. In different applicable environment, we should make a reasonable choice. So in the usual use of cold drawing wire and wire, according to their own needs to choose, although the length of the same, but the performance is not the same.

stainless steel crimped wire mesh...

stainless steel crimped wire mesh 【stainless steel crimped wire mesh】

Read More

Popular articles

1. It is very important to measure the galvanized iron wire automatically from the cargo reel to the drum, which is very important to the extension characteristics and working life of galvanized iron wire.

- 2.7*2.25mm indicates that the two strands are 2.7mm silk, and the thorn strands are 2.25mm silk.

Greenhouse special electroplating process iron wire blackening solution:

Latest articles

-

-

Galvanized hexagonal mesh uses: building wall fixed, heat preservation, heat insulation; Power plant piping, boiler heating; Anti-freezing, residential protection, landscaping protection; Raise chicken and duck, isolate chicken and duck house, play the role of protecting poultry; Protect and support seawalls, hillsides, roads and Bridges and other waterworks.

-

-

3, a wide variety of specifications, a variety of shapes you choose, both European and American style and today’s popular fashion, full noble and modern beauty.

-

Post time: 14-06-24 -

Blade thorn rope because the volume is relatively large so thorn rope factory is used to packaging treatment.

Links

- In terms of performance, the e7rtc plug delivers impressive results. Its high-speed processing capabilities mean that commands are executed promptly, reducing latency and improving overall system responsiveness. Additionally, the plug's energy-efficient design helps maintain optimal power usage, contributing to reduced electricity bills and environmental sustainability.

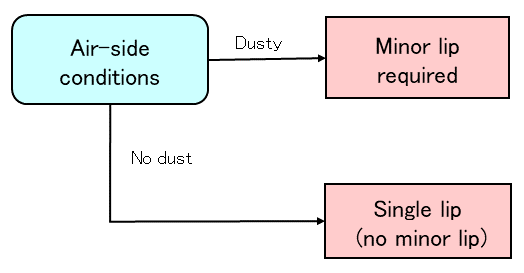

Also known as a Rotary Shaft Seal, Shaft Seal, Lip Seal, Elastomeric Lip Seal or any variation of these. It is a simple device for excluding dust, dirt, water or any other contaminant whilst retaining lubricant in rotary shaft equipment. Generally, it has been developed as a means of protecting the bearings of rotating shafts.

- Despite the added cost compared to single seals, the long-term benefits of double oil seals, including improved reliability, reduced maintenance, and enhanced safety, make them a wise investment for many industries. They not only contribute to the smooth operation of machinery but also play a significant role in environmental sustainability by minimizing oil spills and waste.

Types Of Oil Seal NBC Offer

Without minor lip

⑦

Failure to install oil seals correctly can lead to failure. Factors such as knocking the seal into place may cause its spring to tilt in the bore or be out of alignment. Consider switching to a solid adhesive and applying it around the surface of the spring to prevent it from loosening.

One way to identify a seal that has not been fitted correctly is to check the rough shear of the rubber. To resolve this issue, align the mounting tool before positioning the seal in place.

Step-by-step plan for correct installation

Table 2 a): Common types of oil seals (with spring)

Like any element of the engine, oil seals are subject to wear. Over time they can lead to possible leaks of lubricating liquid.

e3 22 spark plug. By analyzing vast amounts of data from vehicle sensors and engine performance monitors, these smart spark plugs can adapt to changing conditions in real-time, optimizing ignition timing and fuel delivery for maximum efficiency.

e3 22 spark plug. By analyzing vast amounts of data from vehicle sensors and engine performance monitors, these smart spark plugs can adapt to changing conditions in real-time, optimizing ignition timing and fuel delivery for maximum efficiency.Its sealing edge comes in full contact with the shaft surface in order to provide excellent sealing performance.

(See Figure 3.)

Regular inspection and maintenance of rubber valve cover gaskets are essential to identify signs of wear, damage, or leakage. Proper replacement of worn or damaged gaskets is crucial for maintaining the integrity and performance of the engine. Adhering to recommended service intervals and using high-quality replacement components are essential for optimizing the performance and longevity of the vehicle's engine.

In the UK, customers have a range of options for purchasing oil seals. There are several reputable UK gasket manufacturers that offer a wide selection of oil seals to meet various industrial needs.

cmr5h spark plug. A strong and consistent spark helps to ensure that your engine runs smoothly and efficiently, reducing the risk of misfires and other issues that can affect performance.