wire for soldering

Latest articles

wire for soldering

Post time: 10-06-22...

wire for soldering 【wire for soldering】

Read Morewire for soldering

...

wire for soldering 【wire for soldering】

Read More

wire for soldering

Post time: 14-12-22...

wire for soldering 【wire for soldering】

Read MoreIn summary, as a commonly used anticorrosive material, electrogalvanized wire has good corrosion resistance. Its corrosion resistance mainly depends on the thickness, uniformity and structure of zinc layer, substrate material and environmental conditions and other factors. Through reasonable electroplating process and material selection, the corrosion resistance of electrogalvanized wire can be improved and its service life can be extended.

wire for soldering...

wire for soldering 【wire for soldering】

Read More

wire for soldering

Post time: 02-08-22...

wire for soldering 【wire for soldering】

Read Morewire for soldering

...

wire for soldering 【wire for soldering】

Read MoreRing corn with: used as a ring corn net, generally use mesh 5cm*7cm or 5cm*5cm of the original galvanized welding net, wire diameter from 1.8mm-2.3mm, height of 1.2m – 1.8m.

wire for soldering...

wire for soldering 【wire for soldering】

Read More

wire for solderingDid not do the adhesion test of powder spraying or fluorocarbon spray on the packaging galvanized wire, but there are two points for reference: one, in the sealed or air circulation environment, non-metallic volatiles can corrosion zinc coating; Second, zinc above 230 degrees (c) will brittle the base metal. After powder spraying and fluorocarbon spraying, it is necessary to bake at a higher temperature and in a sealed environment, causing rapid corrosion of zinc, resulting in loose corrosion film resulting in decreased adhesion of coating, and even leading to brittle situation of steel wire.

...

wire for soldering 【wire for soldering】

Read Morewire for soldering

...

wire for soldering 【wire for soldering】

Read More

wire for soldering

Post time: 27-06-22...

wire for soldering 【wire for soldering】

Read More

Popular articles

- Relatively speaking, the wire is relatively soft, suitable for binding. Disadvantages are low hardness, low tension, easy to stretch, not suitable for building materials. In different applicable environment, we should make a reasonable choice. So in the usual use of cold drawing wire and wire, according to their own needs to choose, although the length of the same, but the performance is not the same.

Stainless steel barbed rope in the way of corrosion is not very, because the surface is not treated but rely on its own raw materials for corrosion resistance, so there will be no chemical reaction.

Post time: 25-04-23- Determine the size of the dog cage based on the dog’s actual adult size. In general, the cage should be three times the size of the dog’s body and give him enough room to turn around and so on.

Latest articles

-

Hot dip galvanized wire is dipped in zinc liquid melted by heating, with fast production speed and thick but uneven coating. The market allows a low thickness of 45 microns and a high of more than 300 microns. The color is dark, the consumption of zinc metal is much, and the matrix metal forms the infiltration layer, the corrosion resistance is good, the outdoor environment of hot dip galvanized wire can be maintained for decades.

-

-

The characteristics of hexagonal net: strong structure, flat surface, with good corrosion resistance, anti oxidation and other characteristics of the use: used for raising chickens, ducks, geese, rabbits and zoo fence, mechanical equipment protection, highway guardrail, sports venues fence, road green belt protection net. The screen in the production of a box shaped container, filled with stone cage, can be used to protect and support the seawall, hillside, road and bridge, reservoirs and other civil engineering, flood control and flood resistance material, namely (stone cage net, stone cage cage).

-

Large aperture hexagonal net is widely used in mountain, embankment protection, railway and highway isolation barrier, river channel management, soil consolidation berm, water conservancy engineering construction, rivers, DAMS and seawall anti-erosion protection and reservoir river interception, animal husbandry, grassland isolation guardrail, etc.

-

Post time: 01-06-22 -

Through the maintenance of galvanized wire, it can not only greatly prolong its service life, but also improve its efficiency in the daily use process. Because the labeled electrode potential of zinc is -0.762v, which is negative than iron, zinc becomes the anode when the galvanic cell is formed after being corroded by the medium. It itself is dissolved to protect the steel matrix. The duration of the protection of galvanized wire layer has a great relationship with the thickness.

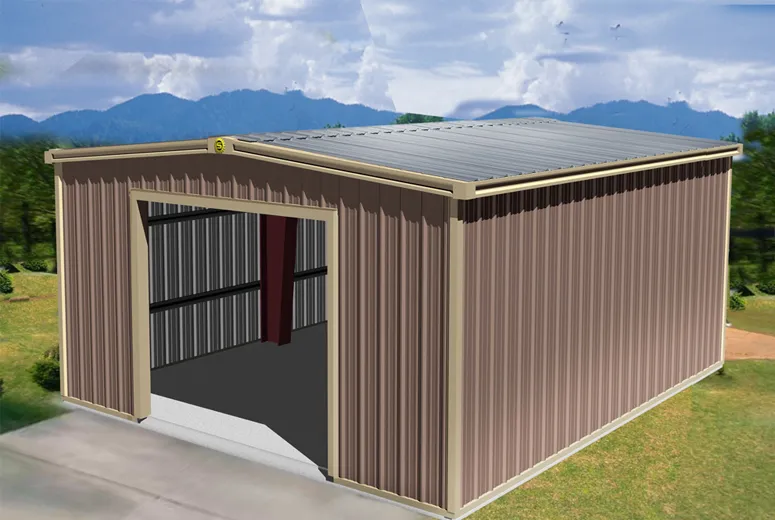

Conclusion The Future of Metal Shops

In today's world, sustainability is more important than ever. A metal workshop that includes living quarters can also incorporate eco-friendly practices. Using sustainable materials, implementing solar panels, and creating recycling stations for metal scraps are just a few ways to ensure that craftsmanship does not come at the expense of the environment.

Moreover, metal structures require significantly less maintenance. Regular inspections and occasional cleaning are usually all that is needed to keep a metal building in prime condition. This durability translates into cost savings over time, as homeowners can avoid the frequent repair and replacement costs associated with other building materials.

residential metal shop buildings

Additionally, the efficiency of the modular production process means that less labor is required on-site. This translates to lower labor costs and reduced construction times. Businesses can invest these savings back into their operations, enhancing productivity and growth.

1. Size and Dimensions The most significant factor affecting the price of metal garage kits is their size. Smaller single-car garages can start at around $1,500 to $3,000, while larger models, which can accommodate multiple vehicles or serve as workshops, can range from $5,000 to $10,000 or more. Custom sizes will typically be priced higher, as special modifications involve additional material costs and engineering.

In recent years, the trend of utilizing reclaimed materials in construction and design has gained significant momentum. Among these materials, barn tin holds a prominent position due to its unique aesthetic, durability, and rustic charm. For those interested in reinvigorating their spaces with a touch of country elegance, strong barn tin for sale presents a fantastic opportunity that goes beyond mere decoration.

Assembled metal sheds are designed with user-friendliness in mind. Many manufacturers offer pre-fabricated kits that come with all necessary components, making the assembly process straightforward and manageable even for those with minimal DIY experience. Detailed instructions and pre-drilled parts simplify construction, allowing users to have their shed up and running in a matter of hours rather than days. This feature is particularly beneficial for those looking for immediate storage solutions without the need for professional installation.

A key component of warehouse design is ensuring safety and compliance with regulations. Proper design elements, such as wide aisles for safe material handling, adequate lighting, and proper ventilation, contribute to a safer working environment. Furthermore, compliance with local building codes and safety regulations is non-negotiable, necessitating timely consultation with professionals to ensure that designs adhere to legal requirements.

In conclusion, a homemade metal shed can provide lasting value to your property. With thoughtful planning, diligent assembly, and regular maintenance, you can create a durable and functional space that meets your needs for years to come. Whether you’re an avid gardener or simply need extra storage, building a metal shed can be a fulfilling DIY project that pays off in practical benefits.

However, as with any construction method, there are challenges associated with prefab industrial buildings. While the initial design upfront can be more complex, leading to longer design times, this is often offset by the speed of construction later in the process. Additionally, misconceptions about the durability and quality of modular buildings persist, but advancements in design and manufacturing technology have addressed these concerns. Today’s prefab structures are built to last, catering to both aesthetic and functional requirements.

And, in the effort to keep spending low and ROI high, many business owners are opting for more cost-effective business materials.

In today’s environmentally conscious world, the sustainability of construction materials is a significant concern. Steel is one of the most recycled materials globally; it can be produced from recycled steel and can be recycled again at the end of its life cycle. This makes steel structure buildings a more eco-friendly option compared to traditional materials. Using steel reduces the need for new raw materials, which can have a positive environmental impact, thus aligning with the growing trend of sustainable construction.

Purchasing Your Metal Garage Kit

Building a sustainable farm is an ambitious yet attainable goal that offers a pathway towards a more resilient and environmentally friendly future. By combining traditional farming wisdom with innovative practices and technologies, we can create a agricultural model that not only feeds the growing population but also protects the planet for generations to come. Sustainable farming is not merely a trend; it is a critical strategy for ensuring food security and ecological balance in a rapidly changing world.

The flexibility of prefabricated buildings is another key advantage. They can be designed to meet diverse industrial requirements, from warehouses and manufacturing plants to retail spaces and office buildings. The modular nature of prefabricated units allows for easy customization to suit specific operational needs. Additionally, as businesses grow or change, these structures can be reconfigured, expanded, or relocated with relative ease compared to conventional buildings.

The Ultimate Guide to 8 x 4 Metal Sheds Durable Storage Solutions for Your Needs

Industrial buildings play a crucial role in the economic framework of any nation. These structures are not merely functional spaces for manufacturing and processing; they serve as the backbone for job creation, innovation, and overall economic growth. Understanding the significance of industrial buildings in the context of economic development is essential for policymakers, investors, and business leaders alike.

Overall, prefabricated metal building prices can vary based on various factors, including size, materials, location, and customization. Understanding these variables allows potential buyers to make informed decisions that align with their budget and project requirements. By investing in a prefabricated metal structure, buyers can not only save money upfront but also enjoy the long-term benefits of reduced maintenance costs, quicker construction times, and energy efficiency. As this innovative building solution continues to evolve, it remains a valuable option for anyone considering construction or expansion.

Structural Design and Versatility

Farm buildings serve various purposes, from housing livestock to storing equipment and crops. The design and construction of these structures significantly impact the efficiency of farming operations. New farm buildings are designed with precision, taking into consideration not only the needs of the farmer but also those of the animals and the environment.

Design Flexibility

In summary, a 6x4 ft metal shed offers a myriad of benefits that cater to the diverse needs of homeowners. Its durability, security features, space efficiency, low maintenance requirements, eco-friendliness, and versatility make it an attractive addition to any property. Whether you’re looking to declutter your garden, safeguard your tools, or create a functional outdoor workspace, investing in a metal shed could be one of the best decisions you make for your home. A metal shed isn’t just a storage solution—it’s an enhancement to your lifestyle.

In the corner of a sprawling garden or nestled between towering trees, a little metal shed often stands quietly, a humble yet intriguing structure that has captured the imagination of many. While it may serve as a simple storage unit, the charm of the little metal shed transcends its primary function, offering a canvas for creativity, nostalgia, and practicality.

As the agricultural sector continues to evolve, farmers are constantly seeking innovative solutions to improve productivity and efficiency. One such solution gaining traction is the use of metal agricultural sheds. These structures, composed of durable materials like steel and aluminum, are revolutionizing the way farmers manage their operations.

Durability and Longevity

The Appeal of Metal Barns

3. Energy Efficiency If you plan to use your shed for activities that require more comfort, consider energy-efficient frames. Look for frames with good insulation properties and double-glazed glass to keep your shed warm during winter and cool during summer.

5. How to prevent water leakage in steel warehouse building:

Design and Planning

5. Customization and Additions Many buyers choose to customize their metal buildings by adding features such as windows, doors, climate control systems, and enhanced safety measures. Each addition can contribute to a higher overall price.

C: Hygienic and Sanitary Design:

Key Contributions to the Construction Process

Furthermore, there is a growing trend toward sustainable practices within the metal steel industry. Many manufacturers are investing in eco-friendly materials and methods, such as using recycled steel and implementing energy-efficient manufacturing processes. This commitment not only aligns with global sustainability goals but also appeals to an increasingly environmentally conscious consumer base.

The Advantages of Prefab RV Carports Protecting Your Investment

Steel Warehouse Buildings

Light industrial buildings typically range from 10,000 to 100,000 square feet and are designed to accommodate a variety of light manufacturing and warehousing activities. Unlike heavy industrial facilities, which are often large and require significant infrastructure investments, light industrial buildings are more flexible and can support operations such as assembly, packaging, and distribution of goods. This makes them ideal for businesses that require space for light production without the intense resource demands of heavy industry.

Conclusion

The steel structure is widely used in industrial buildings. Steel structure warehouse means that the main load-bearing components are composed of steel. Including steel columns, steel beams, steel structure foundations, steel roof trusses, and steel roofs, note that the walls of steel structures can also be maintained with brick walls. Due to the increase in steel production, many have begun to use steel structure warehouses, which can be divided into light and heavy steel structure workshops. Industrial and civil buildings constructed with steel are called steel structures.

The advantages of steel warehouse construction are as follows:

1. Wide range of uses, suitable for factories, warehouses, office buildings, gymnasiums, hangars, etc. It is not only suitable for single-story long-span buildings, but also for the construction of multi-story or high-rise buildings.

2. The building is simple and the construction period is short. All components are prefabricated in the factory, and the site only needs to be assembled easily, which greatly shortens the construction period. A building of 6,000 square meters can be basically installed in just 40 days.

3. Durable and easy to maintain, steel structure buildings can resist harsh weather and only need simple maintenance.

4. Beautiful and practical, the lines of the steel structure building are simple and smooth, with a modern sense. Colored wall panels are available in a variety of colours, and other materials are also available for the walls, allowing for greater flexibility.5. The construction cost is reasonable, the steel structure building is light in weight, reduces the basic cost, the construction speed is fast, and it can be completed and put into production as soon as possible, and the comprehensive economic benefit is much better than that of the concrete structure building.

The right choice in high R-value insulation is yet another way to limit overhead spending. Not only will it keep your warehouse at a cozy 70 degrees, but it can also limit indoor humidity that can warp products like furniture and books.

In conclusion, industrial shed design is a multi-faceted process that requires careful consideration of various factors, including functionality, layout, materials, sustainability, technology, safety, and location. By prioritizing these elements, businesses can create industrial sheds that not only enhance operational capabilities but also contribute positively to the environment and the well-being of their workforce. As the manufacturing landscape continues to evolve, embracing innovative design principles will be essential for future success.