framing nails coil

Latest articles

framing nails coil

...

framing nails coil 【framing nails coil】

Read Moreframing nails coil

...

framing nails coil 【framing nails coil】

Read Moreframing nails coil

...

framing nails coil 【framing nails coil】

Read Moreframing nails coil

...

framing nails coil 【framing nails coil】

Read Moreframing nails coil

...

framing nails coil 【framing nails coil】

Read More

framing nails coil

Post time: 04-08-22...

framing nails coil 【framing nails coil】

Read Moreframing nails coil

...

framing nails coil 【framing nails coil】

Read More(1) Protect and support seawalls, hillsides, roads and Bridges, river courses and other water conservancy projects;

framing nails coil...

framing nails coil 【framing nails coil】

Read More

framing nails coilPVC coated barbed rope is widely used for railway highway protection, but also for safety protection of rivers, embankments and seawalls, so as to better protect the safety of people and animals.

...

framing nails coil 【framing nails coil】

Read MoreThe hoop diameter of 8mm is combined with the cement column guardrail specially customized and equipped with nuts and anti-theft washers. The surface treatment is galvanized, respectively. There are three kinds of bracket hoop at the column cap, bracket hoop at the center column, bracket hoop with encryption bracket, etc. The protective effect of nematocyst rolling cage is good.

framing nails coil...

framing nails coil 【framing nails coil】

Read More

Popular articles

- Powder coating color is divided into: blade thorn rope blue, grass green, dark green, yellow. Spray blade gill net is made of hot-dip galvanized steel plate or stainless steel sheet stamped out of sharp knife sheet, high tension galvanized steel wire or stainless steel wire as core wire combination of blocking devices. Because the shape of the thorn rope is not easy to contact, so it can reach excellent protective barrier effect. The primary raw materials of products are galvanized sheet, stainless steel plate, high quality low carbon steel wire (electric galvanized, hot galvanized, coated plastic, plastic spray) wire, blue, green, yellow and other colors.

Galvanized iron wire can be divided into hot-dip galvanized iron wire and cold galvanized iron wire according to different processing methods. Galvanized iron wire is more prominent in its corrosion resistance. Galvanized iron wire has good toughness and elasticity, the amount of zinc can reach 300 g/square meter, with thick galvanized layer, strong corrosion resistance and other characteristics. Galvanized iron wire products are widely used in construction, handicrafts, wire mesh preparation, the production of galvanized hook mesh, wall mesh, highway guardrail, product packaging and daily civilian and other fields.

Latest articles

-

-

Enclosure to calculate the use of barbed rope, so as to reasonably plan to purchase the amount of barbed rope to facilitate construction.

-

The drawing process of waste product drawing process has a great influence on product function. Generally, large total surface reduction rate (see area reduction rate) and small pass surface reduction rate (about ≤23%) are selected to ensure the tolerance of products. About high strength spring steel wire, the exit temperature of each pass steel wire should be controlled when drawing below 150℃, to prevent the steel wire from changing cracks due to strain aging, which is the main disadvantage of steel wire obsoletion.

-

The screen is made into a box-like container, with stone filled with cages, can be used to protect and support seawall, hillside, road and bridge, reservoir and other civil engineering, flood control and flood resistance is a good material.

-

-

(1) Protect and support seawalls, hillsides, roads and Bridges, river courses and other water conservancy projects;

pedia, the free encyclopedia

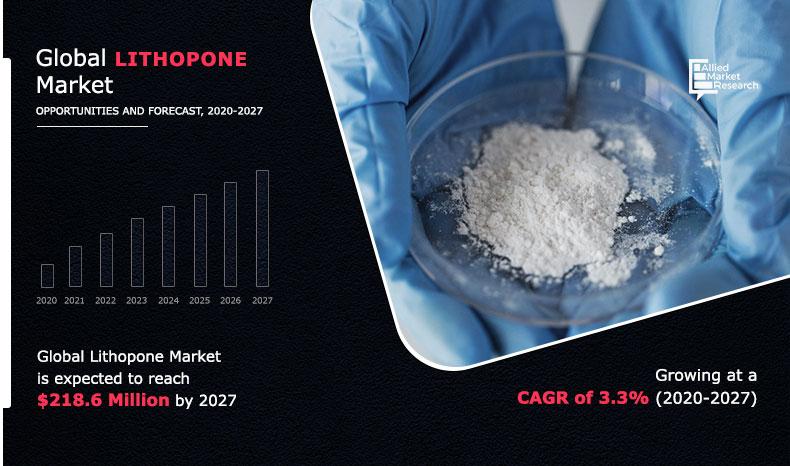

It offers several advantages in various applications. Its excellent opacity and brightness make it a popular choice in the production of paints, coatings, and printing inks, providing a cost-effective alternative to titanium dioxide. Lithopone's chemical stability enhances its durability in outdoor environments, making it suitable for outdoor coatings. Additionally, its low reactivity and compatibility with other pigments contribute to its versatility. Beyond coatings, lithopone finds utility in plastics, rubber, and paper industries. Overall, its multifaceted advantages and broad applications underscore this compound's significance in diverse industrial sectors.

What is the FDA limit for titanium dioxide?

Edelweiss, 14.5 per cent zinc sulphide, 84 per cent barium sulphate, 1.5 per cent carbonate of lime.

Titanium dioxide overnight news

In a 2019 study published in the journal Nanotoxicology, researchers recreated the first phase of digestion in mice and fed them titanium dioxide, then examined whether accumulation occurred in the organs. Researchers wrote: “Significant accumulation of titanium was observed in the liver and intestine of E171-fed mice; in the latter a threefold increase in the number of TiO2 particles was also measured. Titanium accumulation in the liver was associated with necroinflammatory foci containing tissue monocytes/macrophages. Three days after the last dose, increased superoxide production and inflammation were observed in the stomach and intestine. Overall, [this] indicates that the risk for human health associated with dietary exposure to E171 needs to be carefully considered.”

It turns into light gray after being exposed to ultraviolet rays in sunlight for 6 to 7 hours, but it will return to its original color when placed in a dark place. It is easy to oxidize in the air and then agglomerate and deteriorate when exposed to moisture.

Partial substitution of titanium dioxide in liquid paints

Faber argued there hasn't been enough change in these federal regulations in the decades following the FDA's approval of titanium dioxide – especially as others increasingly point to potential health consequences.

The main treatment objects in coagulation stage are suspended organisms and colloidal impurities in water. The perfection of coagulation process has a great influence on subsequent treatment, such as sedimentation, filtration and chlorination, so it is a very important link in Water Treatment process. Polyaluminum chloride and polyferric sulfate are often used in most waterworks.