Although less efficient than wet FGD, it is more suitable for smaller installations due to its lower capital cost Although less efficient than wet FGD, it is more suitable for smaller installations due to its lower capital cost

Although less efficient than wet FGD, it is more suitable for smaller installations due to its lower capital cost Although less efficient than wet FGD, it is more suitable for smaller installations due to its lower capital cost flue gas desulfurization.

flue gas desulfurization.

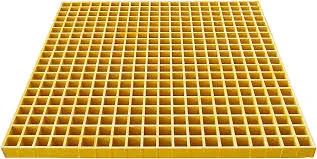

The lightweight nature of fiberglass reduces structural load on buildings, especially when installed on rooftops, minimizing potential safety risks The lightweight nature of fiberglass reduces structural load on buildings, especially when installed on rooftops, minimizing potential safety risks

The lightweight nature of fiberglass reduces structural load on buildings, especially when installed on rooftops, minimizing potential safety risks The lightweight nature of fiberglass reduces structural load on buildings, especially when installed on rooftops, minimizing potential safety risks Molded Grating Fasteners and Accessories

Molded Grating Fasteners and Accessories In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency

In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency