crimped mesh

Latest articles

crimped meshGalvanized diamond net to reduce the impact of the project on the environment, protect the slope protection area of the land, maintain the rock can be fully strong, slope protection hook net through artificial planting grass planting, the implementation of green function. Suitable for any complex terrain, at the same time, does not destroy the original landform, the product is mesh distribution, visual interference, convenient for artificial afforestation, conducive to the environment, engineering and environment integration system flexibility.

...

crimped mesh 【crimped mesh】

Read Morecrimped mesh

...

crimped mesh 【crimped mesh】

Read More

crimped mesh

Post time: 24-04-23...

crimped mesh 【crimped mesh】

Read Morecrimped mesh

...

crimped mesh 【crimped mesh】

Read Morecrimped mesh

...

crimped mesh 【crimped mesh】

Read Morecrimped mesh

...

crimped mesh 【crimped mesh】

Read MoreHexagonal hulanwang custom applications in the channel slope protection work plays a very important role, according to the network performance, it can make is not firmly grasp soil erosion, so hexagonal hulanwang custom slope protection effect is very significant, but also because of this advantage, is widely used in such as channel protection, river bank protection, protection of landslides.

crimped mesh...

crimped mesh 【crimped mesh】

Read More

crimped mesh

Post time: 14-03-23...

crimped mesh 【crimped mesh】

Read More

crimped meshIn order to orchard special electric galvanized shaft wire in alluvial surface to partially remove the surface film layer, surface impurity and other shortcomings can be found and solved according to the basic technology; Excessive foam is caused by soap and soapable surface active substances such as human fat into the tank. A moderate rate of foam production would be fine. The large amount of fine homogeneous particles in the tank can stabilize the foam layer, but the accumulation of too much solid particles will cause explosion.

...

crimped mesh 【crimped mesh】

Read More2, the cage must be strong

crimped mesh...

crimped mesh 【crimped mesh】

Read More

Popular articles

- The wide application of galvanized wire has brought great convenience to people’s production and life, but the production process of iron wire is also not to be underestimated. In industrial production, the production process of galvanized wire should be strictly controlled to ensure the quality of galvanized wire.

The large hexagonal mesh is called the stone cage net. Stone cage net before delivery, must be folded into a simple surface, packed compressed after delivery. Then put it in the right position to open, and then the block diameter suitable stone into the cage, the cover is tight, and then the various stone cage net and the adjacent stone cage net tied up.

Pet cages can be used for indoor and outdoor pet houses. The dog cage is equipped with a fixed food basin and a drinking device, and the rubber pad of the pet cage with a bayonet on the four sides can be assembled. Can be splicing according to the size of the cage, shear, disassembly convenient, easy to clean, can solve the puppy in the ordinary cage pinched foot problem, prevent the puppy in the development of adverse reactions. The bulkhead of the pet cage is breathable and comfortable, which can be used as a heat shield for pets in summer. A puppy with small feet, not a foot, not a pinch.

Latest articles

-

Post time: 28-10-22 -

Any application environment, users want a better the strength of the welded wire mesh, only need to improve its intensity, will make better the habit of using demand, but to be improved in the strength of this product, also need yo have a variety of conditions, will need to see factory in produce what kind of material, the strength of the product also is the material strength, But a manufacturer in the data does not fit the strength requirements, after all, there is no way to make the strength of the product progress, so this is the condition to.

-

Some large roll galvanized wire products in order to meet different industrial needs, will be further processed on the surface, such as the anti-corrosion layer, galvanized, iron plating, aluminum alloy plating, or in the galvanized wire appearance above the copper plating, brass plating, etc., to strengthen the steel wire and colloidal years and capabilities. Generally, galvanized wire products should be well plated and drawn when they are produced, and the sequence of the two processes should be decided according to the production or industrial needs.

-

3. Temporary protection, breeding chickens and ducks, etc., it is recommended that you choose 2mm wire diameter products.

-

-

Links

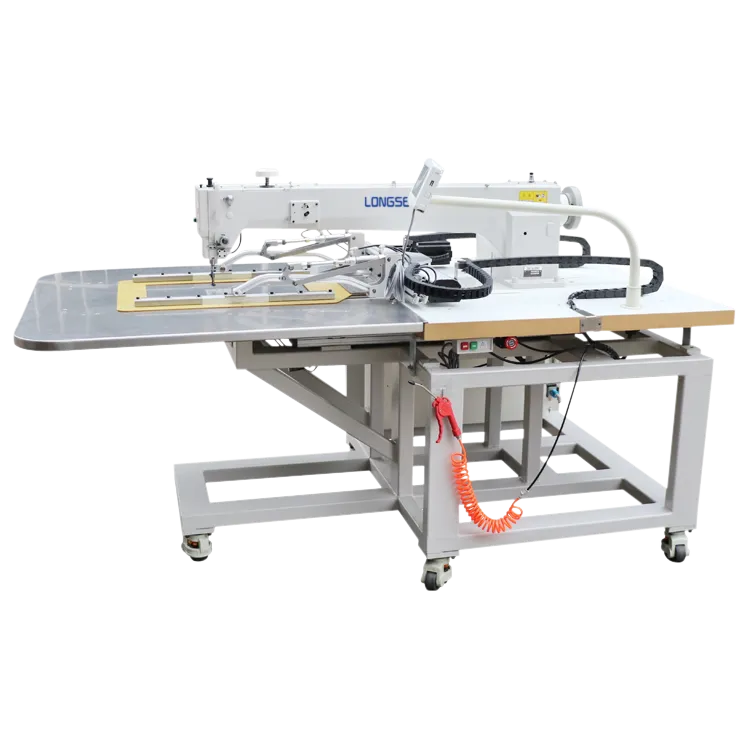

When considering the purchase of a cylinder bed sewing machine, understanding the pricing can help you make an informed decision. The price of a cylinder bed sewing machine varies based on several factors, including brand, model, features, and capabilities. High-end models equipped with advanced features such as automatic thread trimming, programmable patterns, and high-speed motors typically come at a higher price. These machines offer exceptional performance and versatility, making them suitable for professional and industrial use.Mid-range cylinder bed sewing machines provide a balance between cost and functionality. They are often equipped with essential features that meet the needs of small to medium-sized businesses. Entry-level models are more affordable and cater to basic sewing requirements, making them an excellent choice for beginners or hobbyists.It’s essential to consider your specific sewing needs and budget when evaluating cylinder bed sewing machine prices. Investing in a high-quality machine can lead to long-term savings by enhancing productivity and reducing maintenance costs.

A serger, also known as an overlock machine, is an invaluable tool for both professional seamstresses and hobbyists alike. While traditional sewing machines are great for piecing fabrics together, sergers take sewing to another level by finishing edges, preventing fraying, and providing a professional finish that elevates any garment or textile project. Below are several ways you can utilize a serger effectively.

Furthermore, the consistency of the stitching produced by this machine reduces the need for alterations and repairs, which can savings on labor and material costs. The high-quality finish that double needle stitching provides often results in garments that require fewer touch-ups, enhancing overall productivity.

Using a double needle can be an exciting way to enhance your sewing projects. With a little practice, you'll find it an invaluable tool in creating beautifully finished seams and hems. Whether you're a seasoned seamstress or just starting out, incorporating a double needle into your sewing repertoire can bring new life to your creations. Happy sewing!

- The Sumo overlock sewing machine is also built to last. It is made from high-quality materials that are designed to withstand years of heavy use. This means you can rely on this machine to get the job done time and time again, without worrying about it breaking down or needing frequent repairs.

Creative Freedom and Artistic Expression

If you're on a tight budget, there are plenty of affordable single needle quilting machines available on the market. These machines may have fewer features and options, but they still provide excellent quilting results. Some budget-friendly options include the Janome 1600P-QC and the Brother PQ1500SL, which are both highly rated by quilters for their performance and durability.

single needle quilting machine price

The price of zigzag sewing machines can vary widely depending on the above factors. Entry-level machines are typically priced between $100 to $300. These models often provide basic zigzag functionality suitable for beginners and light sewing tasks. Mid-range machines usually cost between $300 to $700 and include more advanced features, making them suitable for hobbyists and semi-professionals. High-end machines, which may be priced from $700 to over $2,000, are designed for serious sewing enthusiasts and professionals, offering extensive features, durability, and high performance.

Conclusion

2. Strong Motor A sewing machine with a powerful motor is essential for tackling multiple layers of fabric. Look for machines that can handle thick materials and maintain consistent speed.

One of the key features of the Cub sewing machine is its compact size. Despite its small footprint, this machine packs a powerful punch, with a high-speed motor that can handle even the toughest fabrics. Whether you are sewing lightweight cotton or thick denim, the Cub sewing machine can handle it all with ease. Its automatic needle threader and drop-in bobbin system make threading and bobbin winding a breeze, while its adjustable stitch length and width allow you to customize your projects to your liking.

cub sewing machine for sale

Reduced Error and Waste

The manufacturing of climbing ropes involves stringent quality control processes. The sewing machines used for this purpose must comply with industry standards and regulations to ensure the final product can withstand intense force and wear. A rope that fails during use can cause serious injury or even fatalities; hence, manufacturers invest significantly in high-quality sewing machinery that guarantees reliability.

twin stitch needle. The double stitching created by these needles is stronger and more secure than a single row of stitching, making it ideal for items that will see a lot of use. This is especially important for items like bags, wallets, and clothing, where seams are subjected to a lot of stress. By using twin stitch needles, you can ensure that your finished products will hold up well over time.

For home sewists, the bobbin shuttle hook offers a blend of simplicity and functionality. Many modern home sewing machines come equipped with user-friendly bobbin systems that simplify the operation. Understanding how to wind a bobbin and thread the shuttle hook correctly can make a significant difference in the sewing experience, preventing common issues such as thread tangling and uneven stitches.

Using a heavy-duty quilting sewing machine can significantly enhance the quilting experience. The powerful motor and durable construction provide reliability, especially when tackling challenging projects. The ability to sew through thick materials with ease reduces frustration and increases efficiency, allowing quilters to complete projects faster.

The hand crank sewing machine is an excellent choice for both newcomers to leather crafting and seasoned professionals. Beginners can learn the fundamentals of sewing while gaining hands-on experience with the mechanics of the machine. For experienced artisans, this machine can serve as a reliable backup for intricate projects or when working in spaces where electric machines may not be practical.

Applications

A Brief History

Programmable pattern sewing machines are invaluable in various sectors, including fashion design, quilting, and home décor. Fashion designers can use these machines to produce intricate designs that would otherwise be time-consuming and challenging to achieve by hand. Quilters benefit from the precision and consistency that programmable machines offer, especially when creating large blocks or repetitive patterns.

automatic bag closer sewing machine. Most models feature user-friendly controls and settings, allowing operators to quickly set up the machine for different bag sizes and materials. This versatility and ease of use make the machine suitable for businesses of all sizes, from small-scale operations to large industrial facilities.

Understanding the Industrial Bag Closing Machine Head

3. Set Up Your Threads You will need to fill two bobbins with thread, as a double needle requires two top threads. Thread both spools of thread on the sewing machine’s thread guide. Thread the machine as you would with a single needle, but remember to separate the two threads when reaching the needle area. Use the same color thread for a uniform look, or different colors for a more striking effect.

What is Twin Needle Sewing Used For?

A heavy-duty sewing machine designed for compound feed is a powerful tool that can handle the toughest sewing tasks with ease. These machines are specifically built to sew through multiple layers of fabric, heavy materials, and even tougher materials like leather and canvas. Whether you're a professional seamstress or a hobbyist, a compound feed heavy-duty sewing machine can make your projects more efficient and produce high-quality results.

2. Efficiency With the ability to perform multiple stitch types in one pass, swing needle machines can significantly speed up the sewing process. This efficiency is particularly beneficial in high-volume production settings where time equals money.

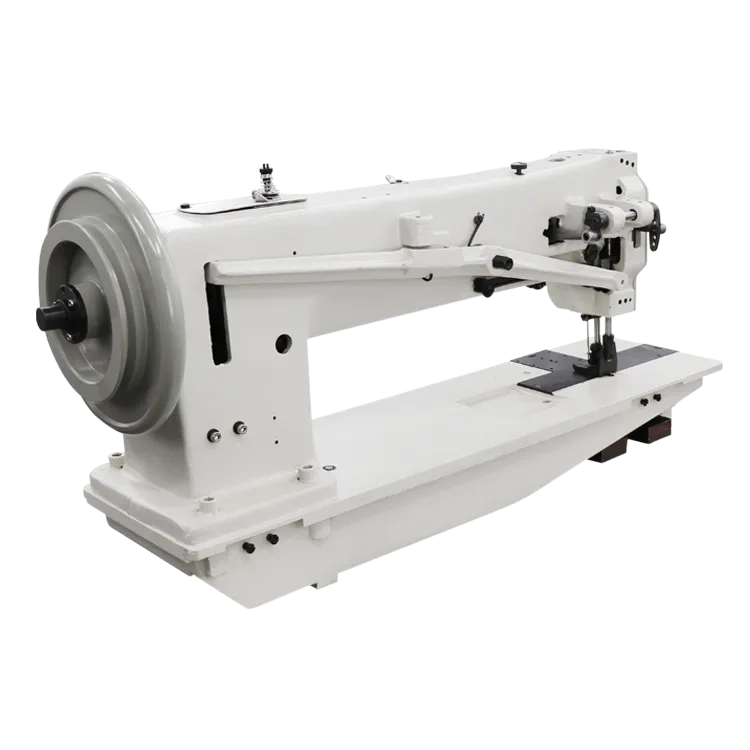

An industrial long arm sewing machine is designed for heavy-duty sewing applications, offering an extended arm length that allows for greater flexibility and space when working with larger pieces of fabric. These machines are ideal for quilting, upholstery, and any project that involves handling sizable materials, such as curtains, blankets, and other bulky items.

Environmental Considerations

3. Ease of Use Many models come with user-friendly features such as automatic stitch settings, built-in thread cutters, and adjustable walking feet, making sewing simpler and more efficient even for beginners.

Why Choose an Industrial Zigzag Sewing Machine?

3. Cost-Effective Production Although the initial investment may be higher than single needle machines, the improved efficiency and increased output can lead to significant cost savings in the long run.

Conclusion

4. Cost-Effective Although the initial investment in an industrial overlocker may be higher than a standard sewing machine, the long-term benefits, including reduced labor costs and improved fabric usage, can lead to significant savings.

industrial overlocker for sale

Ultimate Guide to Heavy Duty Sewing Machines

One of the primary advantages of using the double needle stretch stitch is its durability. Traditional straight stitches may break when sewing on stretchy materials because they do not have the ability to stretch. The double needle stretch stitch, on the other hand, provides the necessary give, allowing for comfortable movement in garments. This is particularly important in activewear, dance costumes, and other garments designed for dynamic activities.

1. Heat Sealing Machines These are among the most common types of bag seaming machines. They utilize heat to melt the edges of the bag material, allowing the two sides to bond together as they cool. Heat sealing is particularly effective for plastic and some synthetic materials, providing a reliable closure that is both airtight and waterproof.

What is a Two Needle Embroidery Machine?