Hot dip galvanizing is dipped in zinc liquid melted by heating, with fast production speed and thick but uneven coating. The market allows a low thickness of 45 microns and a high of more than 300 microns. The color is dark, the consumption of zinc metal is much, the formation of infiltration layer with the matrix metal, the corrosion resistance is good, and the outdoor environment of hot dip galvanized can be maintained for decades. Application range of hot dip galvanizing: because the coating is thicker, hot dip galvanizing has better protective performance than electric galvanizing, so it is an important protective coating for iron and steel parts in harsh working environment. Hot-dip galvanized products are widely used in chemical equipment, petroleum processing, Marine exploration, metal structure, power transmission, shipbuilding and other industries, in the field of agriculture such as sprinkler irrigation, greenhouse and construction industry such as water and gas transmission, wire casing, scaffolding, Bridges, highway guardrail and other aspects, has been widely used.

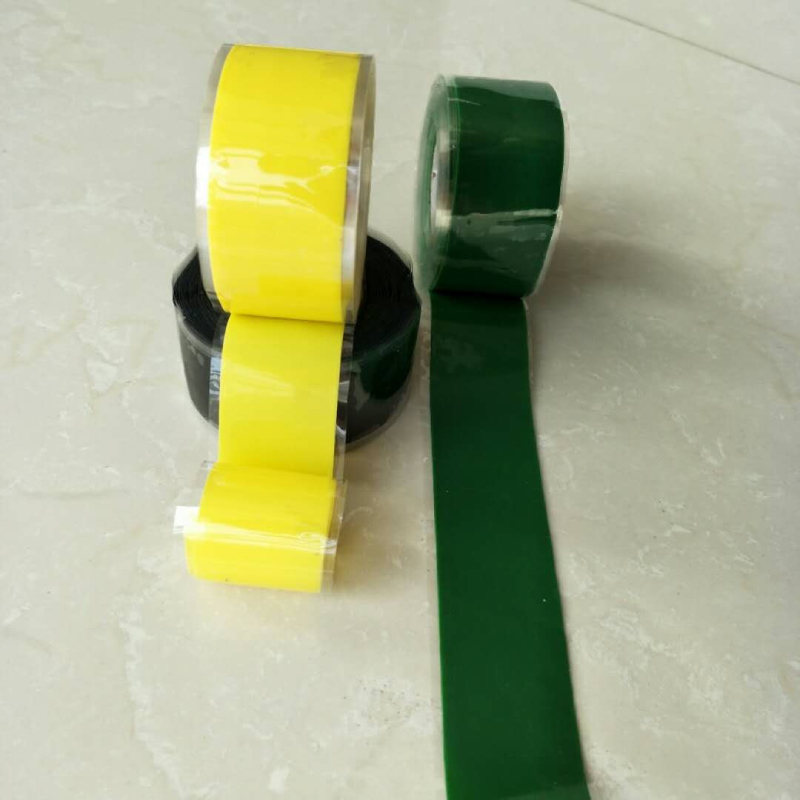

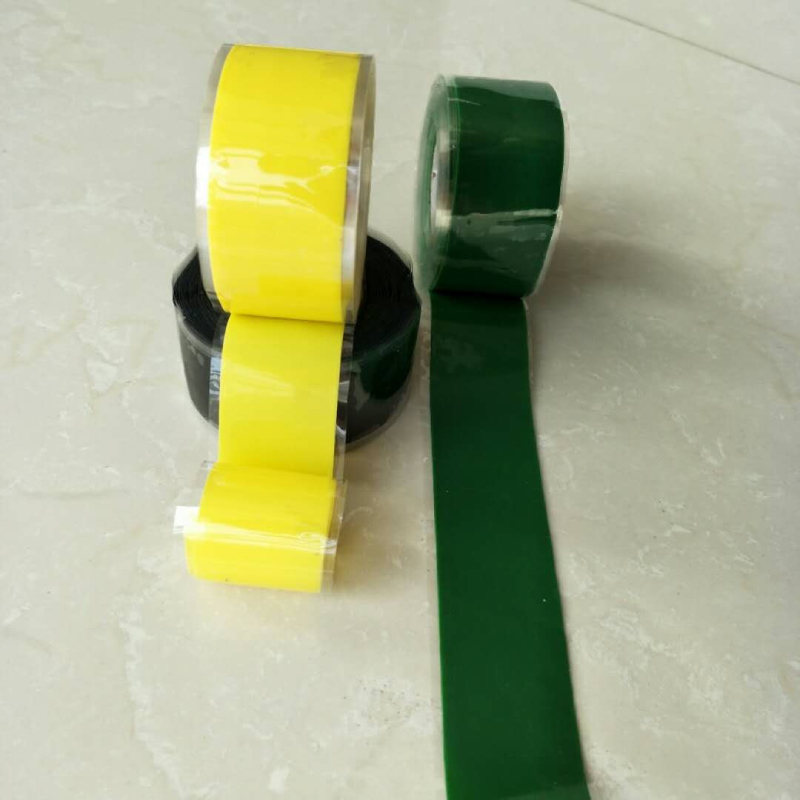

It can be customized with different colors, patterns, or even company logos, adding a touch of style to the otherwise industrial-looking engine compartment It can be customized with different colors, patterns, or even company logos, adding a touch of style to the otherwise industrial-looking engine compartment

It can be customized with different colors, patterns, or even company logos, adding a touch of style to the otherwise industrial-looking engine compartment It can be customized with different colors, patterns, or even company logos, adding a touch of style to the otherwise industrial-looking engine compartment wire harness automotive cloth tape.

wire harness automotive cloth tape.