4 point barbed wire

Latest articles

4 point barbed wire

...

4 point barbed wire 【4 point barbed wire】

Read MoreLong-term exposure to such impurities will result in transition and gap corrosion. The direct solution to this phenomenon is to strengthen the coating of the material to avoid corrosion. Improve the quality of galvanized iron wire, can use the wire that had plated zinc beforehand to pull out when making galvanized iron wire, won’t appear the phenomenon of bad mechanical properties. The toughness of the wire is 15 to 25 per cent higher than that of the drawn and galvanized wire, and in some cases slightly stronger than that of the polished wire.

4 point barbed wire...

4 point barbed wire 【4 point barbed wire】

Read More4 point barbed wire

...

4 point barbed wire 【4 point barbed wire】

Read More

4 point barbed wire

Post time: 05-05-23...

4 point barbed wire 【4 point barbed wire】

Read More

4 point barbed wireFence use: The use of the fence is generally one meter two to two meters a height of the impregnated welding mesh, mesh mostly 6cm, wire diameter from 2mm to 3mm.

...

4 point barbed wire 【4 point barbed wire】

Read More4 point barbed wire

...

4 point barbed wire 【4 point barbed wire】

Read More

4 point barbed wireThe characteristics of hexagonal wire mesh: strong structure, flat surface, with good corrosion resistance, oxidation resistance and so on.

...

4 point barbed wire 【4 point barbed wire】

Read More

4 point barbed wire

Post time: 02-03-23...

4 point barbed wire 【4 point barbed wire】

Read More4 point barbed wire

...

4 point barbed wire 【4 point barbed wire】

Read More4 point barbed wire

...

4 point barbed wire 【4 point barbed wire】

Read More

Popular articles

The production process of large rolls of galvanized wire is a level of drawing, through the mold into a slightly smaller diameter than the original. And so on down to the desired length. One pull is not desirable, must be numbered, from coarse to fine is dependent on metal ductility. If it changes too much it just breaks. After drawing to a certain diameter, galvanized, so that the finished product.

- Because the size of the plane or the surface of the urban area is relatively small, many sports arenas are built in the more prosperous and lively sections, with hexagonal nets to protect the barrier, so it greatly reduces the spherical three-dimensional flying out of the field so affect the traffic order of the bad things.

The galvanizing process of galvanized wire products is a very effective metal anticorrosion method. It is also widely used in other industrial fields. The use of galvanized iron wire is very common in metal structure equipment of various industries. Due to the influence of production technology or other factors, the zinc layer of galvanized wire products will be different to a certain extent, especially ordinary galvanized can not reach the beauty of electric galvanized, the zinc layer of ordinary galvanized wire is mainly for corrosion prevention.

- Heavy hexagonal mesh can be used for slope support, mountain rock face hanging net shotcrete, slope planting green, it can also be made of stone cage cage, stone pad cage, for rivers, DAMS and seawall prevention and control of erosion and reservoirs, river interception with stone cage.

Many pet cages are designed with a small box in the base, so that pets can clean up when they poop, but also convenient for pets’ health. For example, if there is no excreta box, pet excreta will be on the ground, which is quite unhealthy. If you have a box, it’s easy to take the box out and wash the trash away so it doesn’t get all over the place, so it’s more hygienic.

Latest articles

-

-

-

Post time: 28-03-23 -

-

3. When you travel with your dog, it will not cause anxiety to some friends because the dog is scattered in the car, or it will affect safe driving and bring risks.

-

As we all know, the use of hexagonal net protection, can protect the natural environment while protecting the bridge, so as not only to green the ecological environment, but also to prevent soil erosion.

Links

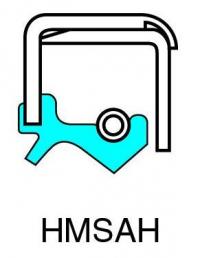

Rubber type

It is important to choose the right type of oil seal for a given application, as it may need to address specific operational concerns such as:

What are Oil Seals? 6 Things DIYers Should Know

Table 5: The major special seals, their shapes, and their features

Different Types Of Bearing Seals

The sealing lip of the RST-D is more heavy-duty, so it can cope with pressures of up to 10 bar at slightly lower rotation speeds.