heavy duty welded wire fence panels

Latest articles

heavy duty welded wire fence panels4. When nothing happens, touch the cage in your hand. If your hands are dry, wipe them with an oilcloth and plate them. There are various ways to protect the structure of the cage from damage. The plate cage can improve the surface finish of the cage, and can eliminate the internal stress of part of the bird cage structure, so that the cage structure is gradually stable, reduce the possibility of deformation.

...

heavy duty welded wire fence panels 【heavy duty welded wire fence panels】

Read Moreheavy duty welded wire fence panels

...

heavy duty welded wire fence panels 【heavy duty welded wire fence panels】

Read Moreheavy duty welded wire fence panels

...

heavy duty welded wire fence panels 【heavy duty welded wire fence panels】

Read More4, according to the wire diameter thickness to adjust zinc dipping time

heavy duty welded wire fence panels...

heavy duty welded wire fence panels 【heavy duty welded wire fence panels】

Read MoreTwo, the influence of steel wire surface roughness

heavy duty welded wire fence panels...

heavy duty welded wire fence panels 【heavy duty welded wire fence panels】

Read Moreheavy duty welded wire fence panels

...

heavy duty welded wire fence panels 【heavy duty welded wire fence panels】

Read Moreheavy duty welded wire fence panels

...

heavy duty welded wire fence panels 【heavy duty welded wire fence panels】

Read Moreheavy duty welded wire fence panels

...

heavy duty welded wire fence panels 【heavy duty welded wire fence panels】

Read Moreheavy duty welded wire fence panels

...

heavy duty welded wire fence panels 【heavy duty welded wire fence panels】

Read More(3) For some use of special paint spraying should be baked, of course, depending on the size of the area, small can be placed in the oven, large can only be dried first, and then to dry parts for processing, lock baking, if other circumstances can only use high temperature tools bit by bit baking. The products that can be baked in the oven should be leveled at room temperature for 15 to 30 minutes, baked at a low temperature of 60 degrees Celsius for half an hour, and then baked at the reserved baking temperature for one and a half hours, and then cooled down.

heavy duty welded wire fence panels...

heavy duty welded wire fence panels 【heavy duty welded wire fence panels】

Read More

Popular articles

- 1. Zinc layer thickness: under normal circumstances, the thicker the zinc layer, the better the corrosion resistance of electrogalvanized wire. This is because the increase in the thickness of the zinc layer can improve the self-corrosion performance of the zinc layer and form a better protective layer.

- After passivation treatment of galvanized layer, it can generate a layer of bright old and beautiful color passivation film, which can significantly improve its protective performance. There are many kinds of galvanized solution, according to its properties can be divided into cyanide bath and cyanide bath two categories. Cyanide zinc plating solution has good dispersion ability and coverage ability, the coating crystal is smooth and meticulous, simple operation, wide application range, in the production is used for a long time.

Latest articles

-

-

Both sides of the galvanized welding net exposed can not be more than 2mm, so as to be qualified. And in the welding mesh of each warp and weft wire cross place, must be welded very firm, and if you want to welding very firm, both sides must have some warp and weft wire out, and the length must be controlled within two millimeters. From the mesh distribution is not uniform, galvanized is not uniform, but also to see whether the welding mesh is qualified standards.

-

-

-

Post time: 17-03-23 -

Links

In conclusion, telescopic security posts represent a smart investment for anyone looking to enhance safety measures. Their versatility, ease of operation, and deterrent capabilities make them a vital addition to any security strategy. As urban environments become increasingly complex and security concerns grow, the adaptation and integration of such innovative solutions will be paramount in safeguarding people and property alike. Investing in telescopic security posts not only enhances safety but also contributes to the efficient management of public and private spaces, balancing the need for security with the desire for accessibility.

In the rapidly evolving urban landscape, ensuring the safety of pedestrians and vehicles is of paramount importance. The Bollard Company has emerged as a key player in this domain, specializing in the manufacturing and design of high-quality bollards. These structures, which serve both functional and aesthetic purposes, are essential for urban planning and public safety. With a commitment to innovation, quality, and sustainability, The Bollard Company has positioned itself as a leader in the industry.

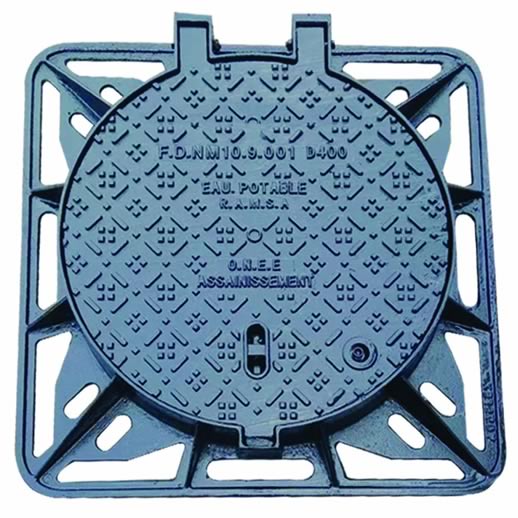

When we traverse the urban landscape, we often take for granted the myriad structures that lie beneath our feet. One such unsung hero is the cast manhole cover. While these circular slabs of steel and iron may seem commonplace, they play a vital role in the infrastructure of our cities, serving both functional and aesthetic purposes that deserve recognition.

Furthermore, innovative designs for storm drain covers have emerged, such as those with permeable elements. These designs allow water to seep through the cover, filtering out pollutants and letting cleaner water enter the drainage network. This not only improves water quality but also reduces the volume of runoff, which is vital in mitigating urban flooding and erosion.

3. Ease of Cleaning Maintenance is crucial in preventing clogs and ensuring hygiene. Opt for grates that are easy to remove and clean regularly.