cost of welded wire mesh

Latest articles

cost of welded wire mesh

...

cost of welded wire mesh 【cost of welded wire mesh】

Read More

cost of welded wire meshWith the improvement of people’s living standards, now many families are raising some small pets, these small pets need a stable nest, pet cage has become a more important choice of people, each pet habits and living habits will choose to adapt to the cage.

...

cost of welded wire mesh 【cost of welded wire mesh】

Read More

cost of welded wire mesh

Post time: 16-03-23...

cost of welded wire mesh 【cost of welded wire mesh】

Read Morecost of welded wire mesh

...

cost of welded wire mesh 【cost of welded wire mesh】

Read More

cost of welded wire meshThe main customers of the thorn rope factory are still targeted at farms and plantations, because the demand for thorn rope is often very large.

...

cost of welded wire mesh 【cost of welded wire mesh】

Read Morecost of welded wire mesh

...

cost of welded wire mesh 【cost of welded wire mesh】

Read More

cost of welded wire mesh

Post time: 17-06-24...

cost of welded wire mesh 【cost of welded wire mesh】

Read More

cost of welded wire mesh

Post time: 01-03-23...

cost of welded wire mesh 【cost of welded wire mesh】

Read Morecost of welded wire mesh

...

cost of welded wire mesh 【cost of welded wire mesh】

Read More

cost of welded wire meshIn the process of composite plating, it is necessary to stir the plating solution to obtain the composite coating in which the particles dispersed in the matrix metal. Stirring methods include mechanical stirring, air stirring, ultrasonic stirring, bath circulation, etc. In the process of production, the acid activation solution can remove the corrosion products and oxide film on the surface of low carbon steel wire without excessive corrosion on the matrix. Galvanized wire can be used zincate galvanized or chloride galvanized and other processes, appropriate additives should be used to obtain the coating required by the standards of low carbon steel wire.

...

cost of welded wire mesh 【cost of welded wire mesh】

Read More

Popular articles

After electric galvanizing hot galvanizing. Electroplated copper and other common applications of screen consumption. The weaving of the binding of the building steel wire mesh has the first braided after plating, plating after weaving and other methods, after the disposal of the wire mesh or wire mesh has good corrosion, oxidation resistance characteristics, can be used in the construction, petroleum, chemical, aquaculture, garden protection, food processing and other industries of reinforcement, protection and insulation.

Latest articles

-

Good word of mouth blade barbed rope must be a reasonable evaluation given by consumers after using, this is because many people feel good after choosing the blade barbed rope, whether in terms of safety protection or in the overall decoration and beautification effect is very good, so that in the actual choice will be more assured, In the eyes of many people, the high quality razor cord will not have problems, or the overall service life is really long, so that we can reduce a lot of cost, and can know whether it is the best.

-

-

Compared with galvanizing, hot-dip galvanizing has lower production cost and less environmental impact than galvanizing. Because the coating obtained is thicker, hot-dip galvanizing has better protective performance than electric galvanizing, so it is an important protective coating for steel parts used in harsh working environment. Hot-dip galvanized products are widely used in chemical equipment, petroleum processing, ocean exploration, metal structure, electric power transmission, shipbuilding and other industries.

-

Post time: 13-07-22 -

Three, the use of different technologies

-

Links

3. Powerful Motor Leather requires more power to sew through compared to regular fabrics. A machine with a more powerful motor ensures consistent stitching and can handle the thickness of leather.

leather jacket sewing machine

Furthermore, computerized sewing machines are equipped with various accessories and attachments that enhance their functionality. From specialized presser feet for quilting or embroidery to walking feet for sewing multiple layers, these tools empower users to take on diverse projects with ease. Many machines also support USB connectivity, allowing users to upload custom designs and patterns, thereby expanding the scope of their sewing creativity.

Understanding the Price of Single Needle Quilting Machines

Heavy-duty sewing machine

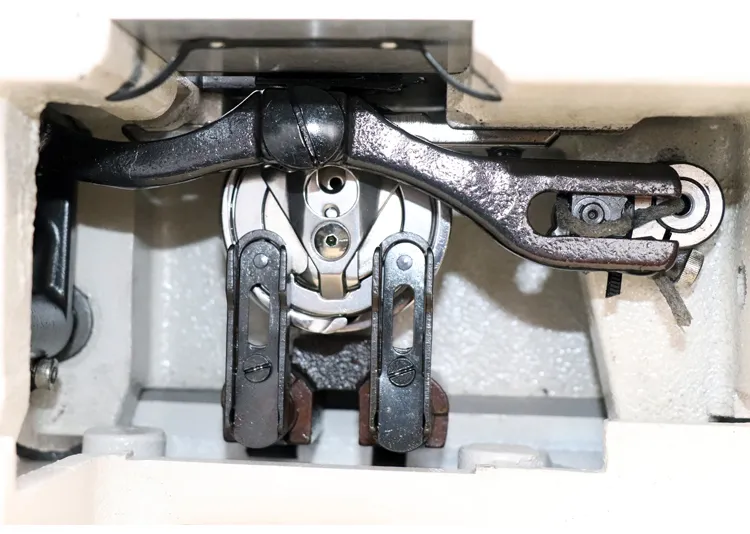

2. The main features of the heavy material sewing machine: the heavy material sewing machine adopts the upper and lower composite feeding and the cross-lifting mechanism of the presser foot to ensure that the upper and lower layers do not shift under any stitch length within the rated range, sewing slippery, viscous sewing material and special long products. The products are neat and the stitches are beautiful; the connecting rod thread take-up mechanism increases the spindle speed; the lower feeding shaft adopts sliding bearings, which reduces the noise and prolongs the service life.

The sewing machine has come a long way since its inception in the 19th century. Initially designed to make stitching quicker and easier, these machines have evolved tremendously over the decades. The Zig Zag Dressmaker Sewing Machine emerged as a powerful innovation, combining traditional straight stitching with a zigzag stitch feature. This dual capability allowed for greater flexibility in techniques and applications, instantly becoming a favorite among sewists.

6. Stitch Type and Length

Another significant benefit of twin needle sewing is its ability to reduce stitching time and improve efficiency. For those who work on larger projects or produce items in bulk, this technique allows for two lines of stitching to be completed at once, effectively cutting down on the time spent sewing. This time-saving benefit can be particularly valuable in a professional setting where meeting deadlines is crucial.

4. Cutting Blade For machines that seal bags at the same time they are cutting, the cutting blade plays a critical role. It ensures that each bag is of uniform size and cuts through the material cleanly. A sharp and well-maintained blade contributes to the overall efficiency and prevents material wastage.

bag closer machine parts

The Evolution of Sewing Machines

In conclusion, the Cub Leather Sewing Machine stands as a premier choice for anyone passionate about leatherworking. Its combination of advanced features, user-friendly design, and remarkable durability make it an essential tool for both beginners and seasoned professionals. Whether crafting custom pieces or tackling repairs, the Cub Leather Sewing Machine provides the reliability and versatility needed to bring creative visions to life. For those looking to explore the art of leathercraft, investing in a quality sewing machine like the Cub is a step toward unlocking endless possibilities.

When sewing stretchy fabrics, a regular sewing machine often produces seams that can easily break or pucker. An overlocker excels in this domain, as it can create stretch seams that allow the fabric to move freely without compromising structural integrity. This technique is excellent for constructing athletic wear, swimwear, and fitted garments, ensuring a comfortable fit and flexibility.

In addition to durability, these machines are also designed with user-friendliness in mind. They come equipped with features like automatic needle threading, easy stitch selection, and adjustable presser foot pressure, making sewing a breeze for even the most inexperienced users.

At its core, the chain stitch machine operates on a unique mechanism that utilizes a single-thread system to create a flexible and durable stitch. Unlike conventional lockstitch machines, which utilize two threads, the chain stitch method allows for a variety of applications, from delicate fabric to heavy materials. The machine’s ability to produce a chain-like stitch makes it particularly advantageous for creating seams that require stretch and durability, such as in athletic wear and denim.

The Evolution and Convenience of Automatic Button Sewing Machines

The ease of use and time-saving capabilities of the automatic buttonhole sewing machine are invaluable, particularly for those handling large sewing projects. For small businesses and home-based seamstresses, the ability to quickly and accurately make buttonholes can significantly enhance productivity and contribute to a more efficient workflow. As a result, these machines have become increasingly popular among fashion designers and tailors looking to streamline their production processes.

Benefits of CNC Machine Sewing

The Evolution and Significance of Union Lockstitch in Textile Manufacturing

One consideration for those new to leatherworking is the learning curve associated with manual machines. It may take time to master the coordination required for smooth operations, but the rewarding final product often outweighs the initial challenges. Aspiring leatherworkers can benefit from attending workshops or watching tutorial videos to build their confidence and skills.

Why Choose a Handheld Sewing Machine?

Conclusion

5. Take Your Time Patience is key. Taking your time while sewing will enhance the quality of your work and ensure that each seam is neatly finished.

Moreover, the Durby machine often comes equipped with user-friendly features such as automatic tension adjustment and intuitive controls. These elements reduce the learning curve for beginners while still catering to the advanced needs of seasoned sewists. The presence of built-in needle threaders and a drop-in bobbin system further streamlines the sewing process, making it an efficient choice for busy crafters.

durby zig zag sewing machine price

Understanding Overlock Chain Stitch A Guide for Seamstresses

Tips for Successful Sewing

sewing heavy canvas

Furthermore, advancements in technology have led to the development of computerized upholstery stitching machines. These machines are equipped with sophisticated software that allows for intricate designs to be programmed and executed with impeccable accuracy. For businesses that prioritize customization and unique design elements, these machines open up endless possibilities. From creating detailed patterns on luxury furniture to crafting personalized interiors in vehicles, computerized sewing machines have extended the creative potential for upholstery designers.

On the higher end, professional-grade fully automatic sewing machines can cost anywhere from $1,500 to over $5,000. These models are equipped with a plethora of features designed for advanced sewers and professionals. They may include high-speed stitching, extensive embroidery designs, customizable settings, and superior build quality. Some high-end machines even offer computerized systems that can connect to design software for creating unique patterns and models.