perforated carbon steel

Latest articles

perforated carbon steelLarge roll galvanized wire is simply galvanized iron wire, usually used wire is often visible, because iron is very easy to be corroded and rusted, so it is necessary to put a layer of other not easy to rust metal plating in the outer layer, to achieve the effect of corrosion resistance and rust resistance, the effect of zinc can do more. Therefore, many customers often require hardware factories to produce galvanized iron wire, which requires the use of galvanized iron wire equipment.

...

perforated carbon steel 【perforated carbon steel】

Read More

perforated carbon steelAnd high-quality data are constrained by production costs and production conditions, so some electric welding mesh manufacturers do not meet this requirement, in this case, there is no way to improve product strength. In addition to data, and produce process, even if again good data, but the factory did not meet the requirements of production process in welding, also can form the product under the high pressure welding, so it is also a kind of strength on the decline, process conditions of different manufacturers also have very big difference, so it formed a shopping mall on the above products are differences of strength.

...

perforated carbon steel 【perforated carbon steel】

Read More

perforated carbon steel

Post time: 28-09-22...

perforated carbon steel 【perforated carbon steel】

Read More

perforated carbon steelIn order to improve the corrosion resistance of steel pipe, the general steel pipe is galvanized. Galvanized steel pipe is divided into hot dip galvanized and electric galvanized. The layer of hot dip galvanized is thick, the cost of electric galvanized is low, and the surface is not very smooth. Used for steel blowing oxygen pipe, generally with small diameter welded steel pipe, specifications from 3/8-2 inches of eight. Made of 08, 10, 15, 20 or 195-Q235 steel strip, in order to prevent corrosion, some should be aluminized.

...

perforated carbon steel 【perforated carbon steel】

Read Moreperforated carbon steel

...

perforated carbon steel 【perforated carbon steel】

Read MoreCold galvanized is in the plating tank through the current unidirectional zinc gradually plated on the metal surface, the production speed is slow, uniform coating, thin thickness, usually only 3-15 microns, bright appearance, poor corrosion resistance, generally a few months will rust. With the rapid development of market economy, all walks of life are improving the production process and quality of products, galvanized iron wire industry is of course no exception. But because of the variety of galvanized iron wire, its characteristics and production technology are not the same.

perforated carbon steel...

perforated carbon steel 【perforated carbon steel】

Read Moreperforated carbon steel

...

perforated carbon steel 【perforated carbon steel】

Read Moreperforated carbon steel

...

perforated carbon steel 【perforated carbon steel】

Read More

perforated carbon steel

Post time: 09-08-22...

perforated carbon steel 【perforated carbon steel】

Read Moreperforated carbon steel

...

perforated carbon steel 【perforated carbon steel】

Read More

Popular articles

Reduce the impact of the project on the environment, protect the slope protection area of land, maintain the rock can be fully strong, slope protection hook flower net through artificial planting grass planting, the implementation of green function. Suitable for any complex terrain, at the same time, does not destroy the original landform, the product is mesh distribution, visual interference, convenient for artificial afforestation, conducive to the environment, engineering and environment integration system flexibility.

Pet cages can be used for indoor and outdoor pet houses. The dog cage is equipped with a fixed food basin and a drinking device, and the rubber pad of the pet cage with a bayonet on the four sides can be assembled. Can be splicing according to the size of the cage, shear, disassembly convenient, easy to clean, can solve the puppy in the ordinary cage pinched foot problem, prevent the puppy in the development of adverse reactions. The bulkhead of the pet cage is breathable and comfortable, which can be used as a heat shield for pets in summer. A puppy with small feet, not a foot, not a pinch.

Post time: 14-02-23

Latest articles

-

-

-

Pet cage has many types, and selective is bigger, pet cages are generally made of wire, with better coarse, then at the bottom with a wheel base, such a simple pet basket was made, in the wheel at the bottom of the mount is for the convenience of the mobile, a pet cages should also adapt to the location of the production in addition to a door, Convenient in pet feeding when more convenient.

-

-

2, can quickly let the dog develop home habits, let it learn to wait for the owner to take it out, prevent it from making the home dirty, dirty its nest.

-

Links

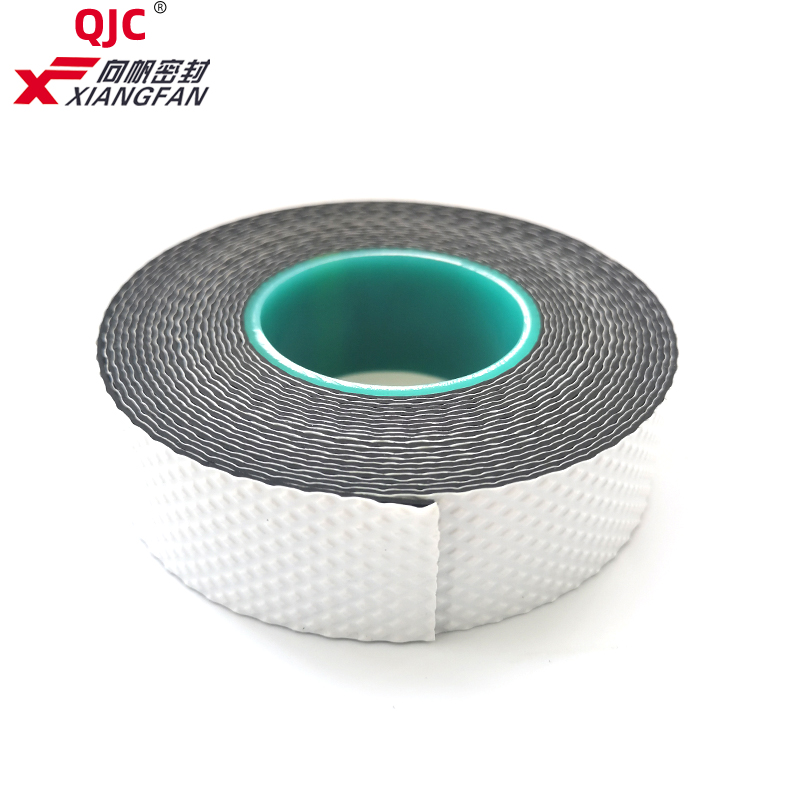

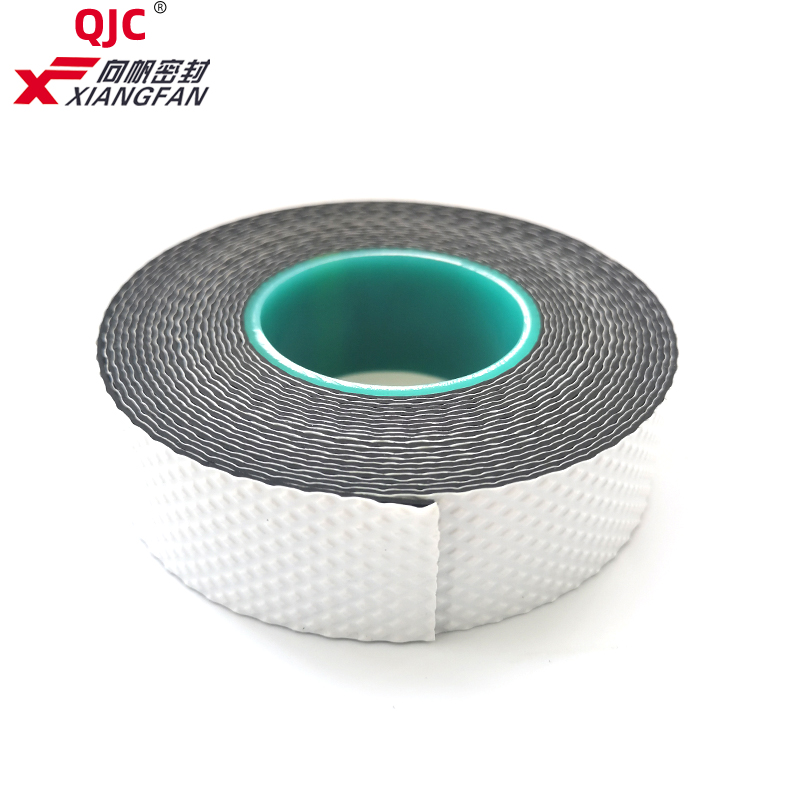

- 3. Temperature Resistance The tape can withstand extreme temperatures ranging from -40°C to 100°C, making it suitable for use in a wide variety of environments.

However, like any product, it is important to remember that while Flex Tape is highly effective for many applications, it may not be suitable for every situation. For example, for structural repairs or tasks that require significant strength, traditional methods such as welding or mechanical fasteners should be considered.

Its non-adhesive nature ensures it won't leave any residue on the wires or components it covers, reducing the risk of electrical shorts or damage Its non-adhesive nature ensures it won't leave any residue on the wires or components it covers, reducing the risk of electrical shorts or damage

Its non-adhesive nature ensures it won't leave any residue on the wires or components it covers, reducing the risk of electrical shorts or damage Its non-adhesive nature ensures it won't leave any residue on the wires or components it covers, reducing the risk of electrical shorts or damage self bonding electrical tape. It also provides excellent electrical insulation, preventing accidental contact with live circuits, and can even be used as a protective layer against electromagnetic interference (EMI) and radio frequency interference (RFI).

self bonding electrical tape. It also provides excellent electrical insulation, preventing accidental contact with live circuits, and can even be used as a protective layer against electromagnetic interference (EMI) and radio frequency interference (RFI).Repairing leaking pipes and pipe joints

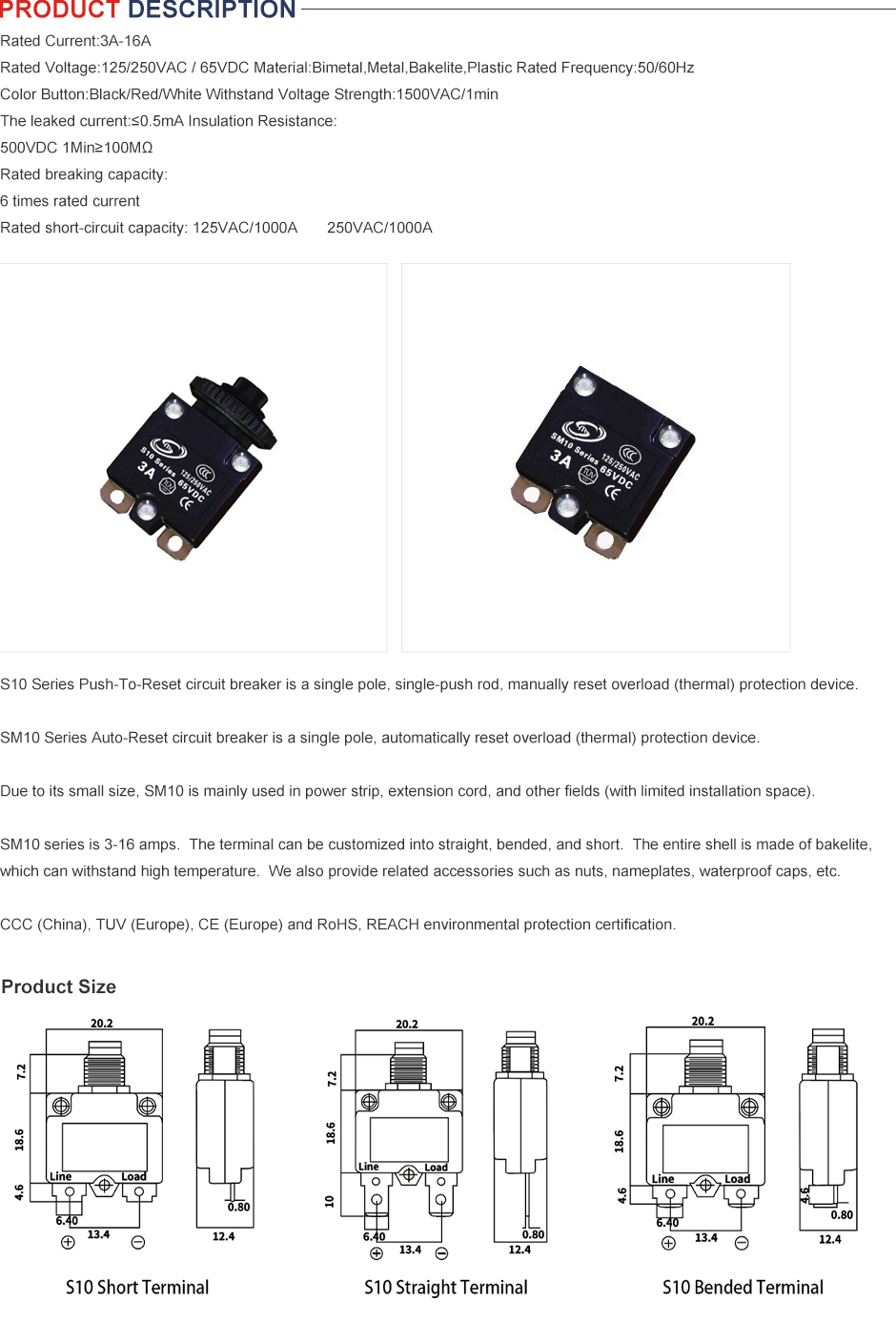

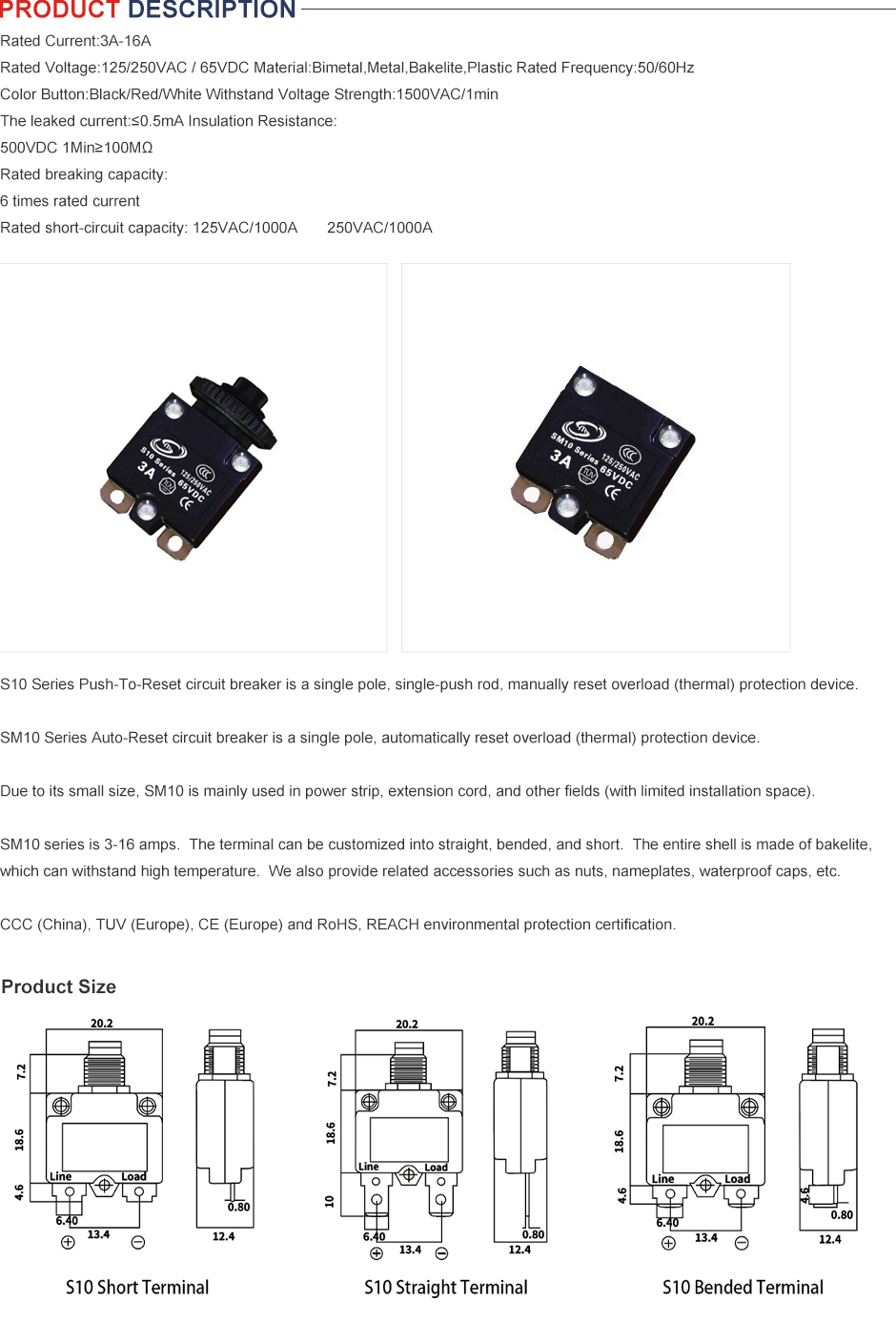

Electrical control boxes are endowed with electrical components such as circuit breakers and transformers since they are engineered to oversee electrical distribution. Their application range and scope transcend both industrial and residential use. Common examples of electrical control boxes include;

Features of self-amalgamating tape

In addition, tapes can also be used to display emergency exit routes, first aid stations, and other vital information that can help workers respond quickly and effectively in the event of an accident In addition, tapes can also be used to display emergency exit routes, first aid stations, and other vital information that can help workers respond quickly and effectively in the event of an accident

In addition, tapes can also be used to display emergency exit routes, first aid stations, and other vital information that can help workers respond quickly and effectively in the event of an accident In addition, tapes can also be used to display emergency exit routes, first aid stations, and other vital information that can help workers respond quickly and effectively in the event of an accident industrial floor tape.

industrial floor tape.Conclusion

butyl rubber tape manufacturers. Their butyl rubber tape is known for its high strength and resistance to oil, fuel, and other harsh chemicals. It is commonly used for sealing body panels, windows, and other components on race cars.

4. Versatility and Applications

It can be easily cleaned with soap and water, and does not require any special cleaning agents It can be easily cleaned with soap and water, and does not require any special cleaning agents

It can be easily cleaned with soap and water, and does not require any special cleaning agents It can be easily cleaned with soap and water, and does not require any special cleaning agents pvc floor tape. This makes it a low-maintenance option that can save time and money in the long run.

pvc floor tape. This makes it a low-maintenance option that can save time and money in the long run.Primary Insulation helps keep the lights on.

Moreover, butyl rubber rolls are employed in medical applications, such as in the production of medical devices and pharmaceutical packaging. The material's non-reactive nature ensures that it does not interact with medications, making it safe for storing sensitive substances.

Insulating tape is also commonly used for temporary repairs. In emergency situations where wires are damaged or exposed, insulating tape can be used to quickly cover and protect them until a permanent solution can be implemented. This can help to prevent further damage and ensure that the electrical system stays operational.

It is used for making watertight seals, waterproofing joints, and temporarily repairing leaks in pipes, hoses and tubes.