white aluminum storm windows

Latest articles

white aluminum storm windows

...

white aluminum storm windows 【white aluminum storm windows】

Read Morewhite aluminum storm windows

...

white aluminum storm windows 【white aluminum storm windows】

Read More

white aluminum storm windows

Post time: 28-11-22...

white aluminum storm windows 【white aluminum storm windows】

Read Morewhite aluminum storm windows

...

white aluminum storm windows 【white aluminum storm windows】

Read Morewhite aluminum storm windows

...

white aluminum storm windows 【white aluminum storm windows】

Read Morewhite aluminum storm windows

...

white aluminum storm windows 【white aluminum storm windows】

Read Morewhite aluminum storm windows

...

white aluminum storm windows 【white aluminum storm windows】

Read More

white aluminum storm windowsIn order to orchard special electric galvanized shaft wire in alluvial surface to partially remove the surface film layer, surface impurity and other shortcomings can be found and solved according to the basic technology; Excessive foam is caused by soap and soapable surface active substances such as human fat into the tank. A moderate rate of foam production would be fine. The large amount of fine homogeneous particles in the tank can stabilize the foam layer, but the accumulation of too much solid particles will cause explosion.

...

white aluminum storm windows 【white aluminum storm windows】

Read More

white aluminum storm windows

Post time: 09-10-22...

white aluminum storm windows 【white aluminum storm windows】

Read Morewhite aluminum storm windows

...

white aluminum storm windows 【white aluminum storm windows】

Read More

Popular articles

Moderate rates of foam formation may be harmless. The presence of small, homogeneous particles of large denier in the tank can stabilize the foam layer, but the accumulation of excessive solid particles can cause an explosion. Using activated carbon mat to remove surface active substances, or through filtration to make the foam is not too stable, this is an effective measure; Other measures should also be taken to reduce the amount of surfactant introduced to Z.

- When in use, wrap into a roll cage. First, its ventilation is good, conducive to the air drying of corn; Second, occupy a small space, convenient drying, good air permeability, light transmission; Third, beautiful and strong, reusable, cost-effective. And in the storage process, it is easy to cover in rain and snow weather to avoid the deterioration of corn mold.

Galvanized hexagonal mesh weaving process: double stranded hexagonal mesh, can be divided into three screws and five screws.

Post time: 17-06-24- ② Electric galvanized shaft wire direct selling shall not be used for waist hoop compression reinforcement, usually not used for all binding.

Latest articles

-

Cold drawing wire is a metal cold processing, with wire rod as raw material, that is, the mouth of the steel bar. Cold drawing wire is a product produced by a series of processes such as shell stripping, which is a common wire. In the development and production of metal materials, cold drawing wire is a very common material, its performance is good, the range of use is very wide, manufacturers in processing are the use of cold processing to produce.

-

-

-

2.7*2.25mm means that the two strands are 2.7mm silk, and the thorns are 2.25mm silk.

-

The appearance quality of cold-drawn low carbon steel wire in each inspection lot shall be all visually inspected. The appearance of steel wire shall not have cracks, burrs, corrosion and mechanical damage affecting mechanical function. Cold-drawn low carbon steel wire with unqualified appearance can be used in engineering after treatment and inspection.

-

When buying large galvanized wire, first look at the hardness of galvanized wire, only after the hardness reaches the standard can be used. The hardness standard of large coil galvanized wire is a very important performance index and an economical test method. However, for the hardness of metal materials, there is not a unified and clear definition including all test methods at home and abroad.

Links

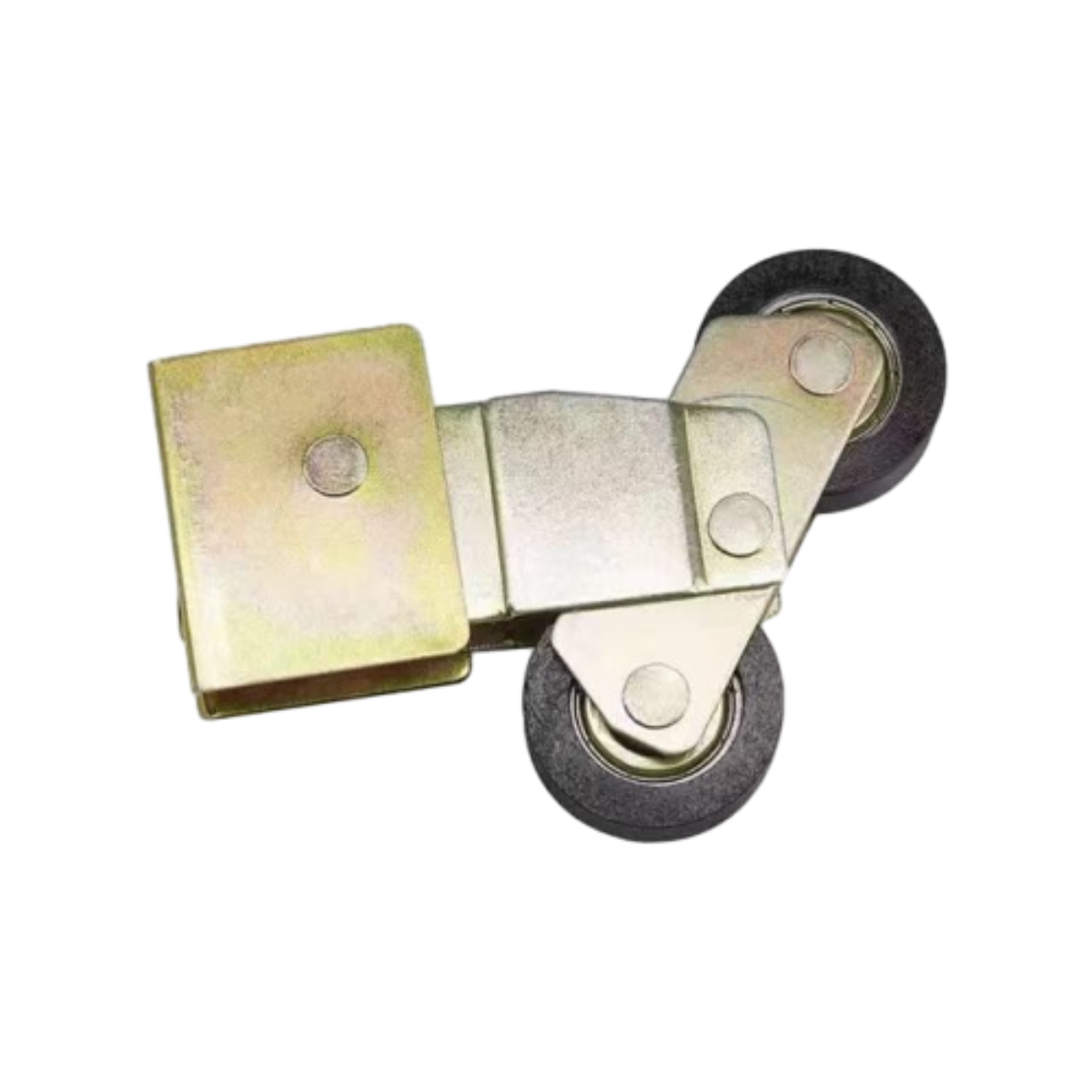

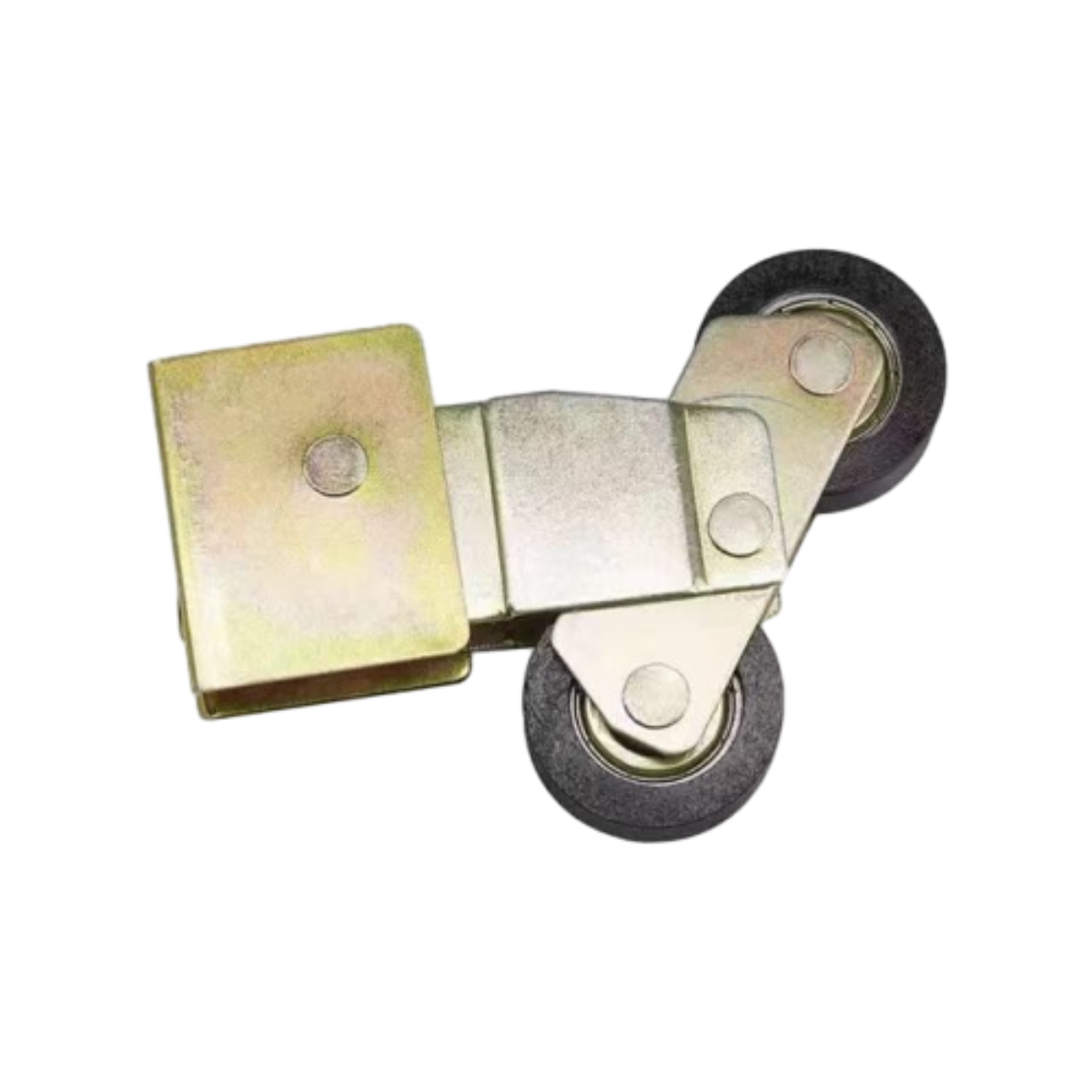

- After the new roller assembly has been installed, it is essential to test the door to ensure that it is functioning correctly. Open and close the door several times to ensure that it moves smoothly along the track without any sticking or resistance. If the door does not operate as it should, it may be necessary to adjust the rollers or track alignment.

Still, iron was the first material to let people build truly tall buildings. The Eiffel Tower, for instance, is actually built out of wrought iron. Wrought iron is strong, but also inconsistent and prone to flaws that are impossible to detect until a particular piece fails catastrophically. This is something that happened regularly throughout the nineteenth century, causing factories to collapse on the heads of the workers below and trains to derail or fall into rivers when the bridges they crossed collapsed. Steel, in comparison, is much more consistent, and as soon as people figured out how to make it in large quantities they began using it for everything. In fact, when people say “wrought iron” in reference to fencing, what they are probably referring to is steel fencing that looks like wrought iron. The confusion might also come from the fact that steel is really just iron worked at higher temperatures to ensure an even distribution of carbon.

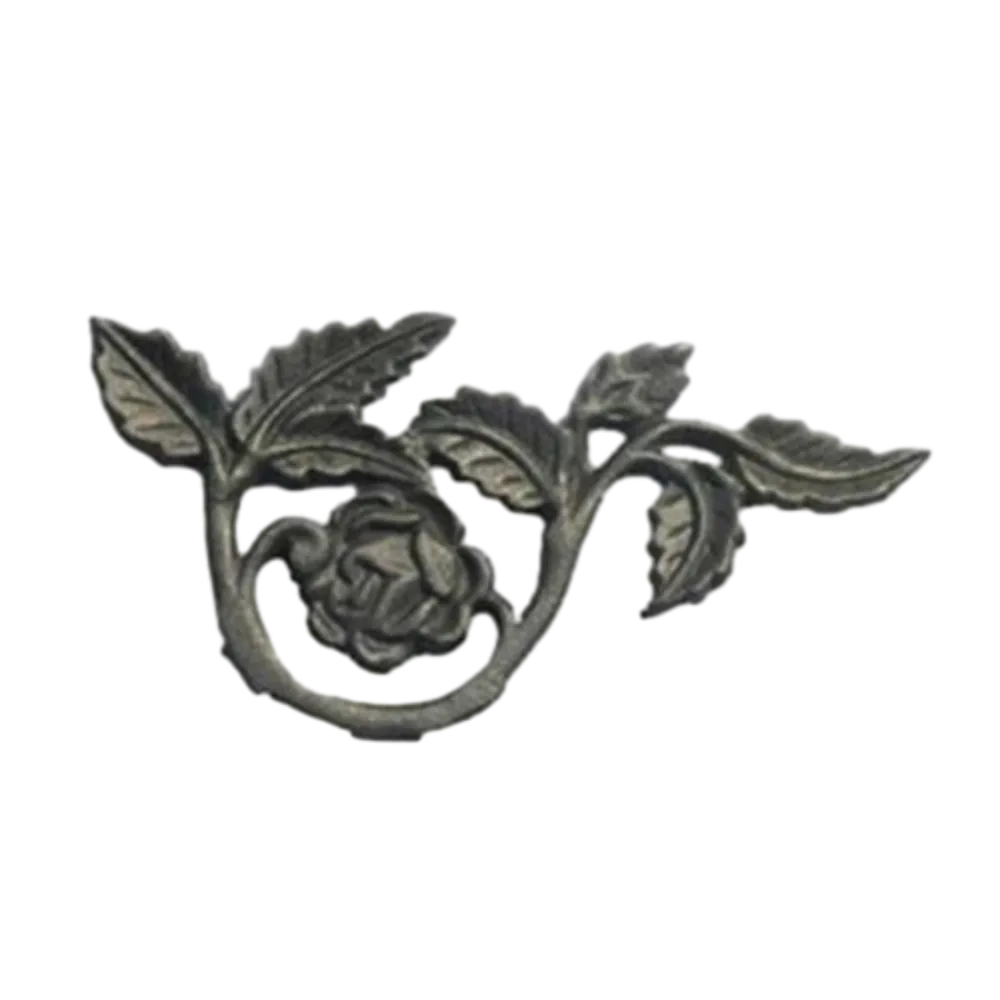

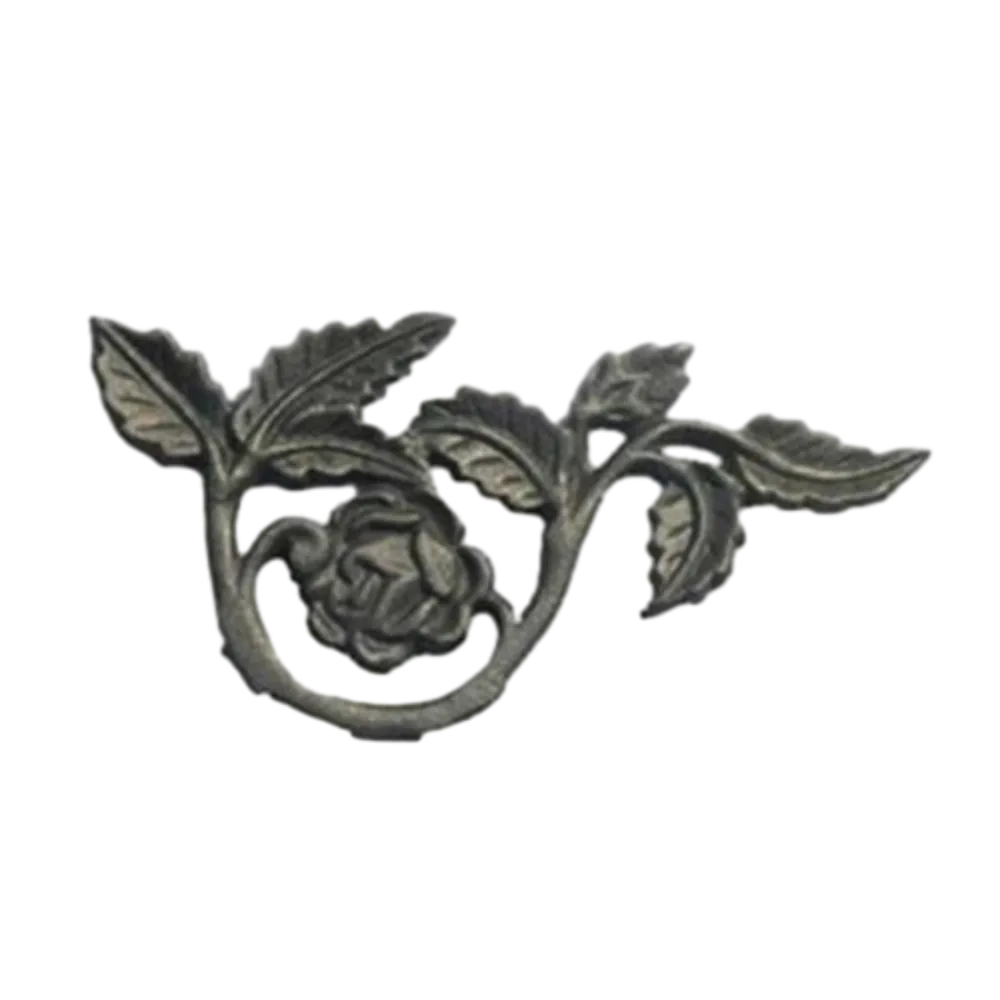

Facts About Wrought Iron Fence

Wrought iron fence is a heavy fencing material made up of gauge square tubing for its vertical pickets and punched channel for its horizontal rails. If you are looking for a heavy-duty fence, a wrought iron fence is the fence for you. This fencing is great for high security settings and a great fence to install if you expect much wear and tear. It is a very beautiful fence. Wrought iron fencing is best installed on level terrain or a retaining wall. Typical wrought iron panels are 48” high X 96” wide, which means that its panels are wider than most aluminum fencing. Panels also weigh about 47 pounds each, making it a heavy material to work with, but it also means a highly sturdy fence once installed. Wrought iron comes only in a black powder coated finish. Wrought iron also requires a bit of maintenance, as it will eventually rust over the years when exposed to the outside environment.

In addition to enhancing the aesthetics of your property, wrought iron gates also provide added security. These gates are sturdy and strong, making it difficult for intruders to gain access to your property. They can be equipped with locks and other security features to further protect your home or business.

wrought iron gate for sale

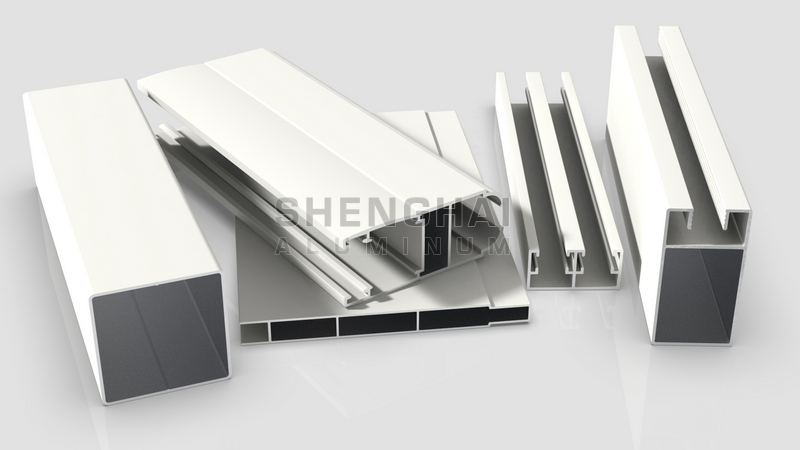

Polyamide transforms aluminium window profiles into outstanding insulators

You can easily choose the specific design or shape of aluminum profile suitable for your windows and doors.

Assembly: If the profiles are to be used in window frames or other assemblies, they will be joined together using mechanical fasteners, adhesives, or other methods.

Wrought iron is the epitome of strength and longevity in the world of fencing. We’re talking about a material that can withstand harsh weather conditions, from scorching heat to freezing cold.

What factors contribute to the high cost of wrought iron?

Modern Applications

While ornamental cast iron panels are known for their durability, regular maintenance is essential to keep them looking their best. Over time, exposure to the elements can lead to corrosion or rust. To prevent this, it is advisable to apply a protective coating periodically. Cleaning the panels gently with mild soap and water will also help preserve their finish and vibrancy.

The coating film should be uniform and tidy, Wrinkles, cracks, bubbles, flow marks, inclusions, stickiness and peeling off of the coating film are not allowed. However, the profile ends allow for partial filmlessness.

You can use them to organize your desk, keep your closet clutter-free, or store seasonal items out of sight You can use them to organize your desk, keep your closet clutter-free, or store seasonal items out of sight

You can use them to organize your desk, keep your closet clutter-free, or store seasonal items out of sight You can use them to organize your desk, keep your closet clutter-free, or store seasonal items out of sight metal box with latch.

metal box with latch. Homeowners can choose one that complements their home's architecture and interior decor Homeowners can choose one that complements their home's architecture and interior decor

Homeowners can choose one that complements their home's architecture and interior decor Homeowners can choose one that complements their home's architecture and interior decor slide co screen door roller. Additionally, these screens can be tailored to fit any size or shape of the doorway, ensuring a perfect fit every time.

slide co screen door roller. Additionally, these screens can be tailored to fit any size or shape of the doorway, ensuring a perfect fit every time.

Why Choose Us As Aluminum Profiles For Doors and Windows Manufacture Supplier

Speaking from personal experience as a welder, steel is a lot easier to work with than iron. If someone manages to break a piece of steel (which isn’t easy), repairing it is a simple matter of properly positioning the pieces and welding them together. In contrast, repairing a cracked or damaged piece of iron means heating the whole piece back up to nearly molten temperatures, then carefully welding it in stages--with pauses to reheat the piece--while sometimes giving it a whack with a hammer and hoping you don’t hear the tell-tale ping of a crack forming somewhere else. Iron is a finicky material.

In addition to its use in the garden or as art, wrought iron can be employed in more functional roles, such as building items like shelving units or brackets. These can add both utility and a rustic or industrial aesthetic to your home environment.