plant cages and supports

Latest articles

plant cages and supportsSmall and medium-sized cat cage, dog cage and fence are mostly pure wire welding, wire diameter is generally between 2-5mm. Of course, the larger the cage, the thicker the wire, because the larger cage has to withstand more force.

...

plant cages and supports 【plant cages and supports】

Read More

plant cages and supports

Post time: 17-05-22...

plant cages and supports 【plant cages and supports】

Read More

plant cages and supportsThe antisepsis of these materials is very different, the use of life is not the same. Cold galvanized cattle net, also known as electroplating, galvanized amount is small, rust in rain, but the price is cheap, the service life is 5-6 years. The amount of zinc on hot dip galvanizing (low zinc and high zinc) is about 60g to 400g, the service life is about 20-60 years, and the corrosion resistance is general.

...

plant cages and supports 【plant cages and supports】

Read Moreplant cages and supports

...

plant cages and supports 【plant cages and supports】

Read Moreplant cages and supports

...

plant cages and supports 【plant cages and supports】

Read More

plant cages and supportsHook fence is made of hook fence for the net surface of the protective net, barrier grid. Material PVC wire, stainless steel wire, good low carbon steel wire, galvanized wire, iron wire hook mesh is made of hook mesh machine for various materials of wire hook knitting, can be divided into two kinds of folding, screwing lock.

...

plant cages and supports 【plant cages and supports】

Read Moreplant cages and supports

...

plant cages and supports 【plant cages and supports】

Read MoreDip is one of the anticorrosion methods of galvanized diamond net. For hook mesh immersion is one of the methods of anti-corrosion, now the domestic more mature method is: powder immersion method, it originated from the fluidized bed method, the so-called fluidized bed is used in the Winkler gas furnace on the oil contact decomposition, and then developed the solid-gas two-phase contact process, gradually used in metal coating. So sometimes it is still called “fluidized bed coating method”, the actual process is to add the powder coating to the bottom of the porous, breathable container, the blower from the bottom into the treated compressed air, so that the powder coating turned to the “fluidization state”. It becomes a fine, evenly distributed powder.

plant cages and supports...

plant cages and supports 【plant cages and supports】

Read More

plant cages and supportsThe corrosion or discoloration of galvanized iron wire in the atmosphere caused by oxygen, moisture and other pollution impurities is called rust or rust. After galvanized iron wire rusting, it will affect the appearance quality, seriously affect the use, and even cause scrap, so galvanized iron wire must be properly kept and pay attention to rust prevention.

...

plant cages and supports 【plant cages and supports】

Read MoreOne is to do a good job of galvanized wire packaging, avoid bumping, to ensure the integrity of the zinc layer;

plant cages and supports...

plant cages and supports 【plant cages and supports】

Read More

Popular articles

Post time: 15-12-22- Relatively speaking, the wire is relatively soft, suitable for binding. Disadvantages are low hardness, low tension, easy to stretch, not suitable for building materials. In different applicable environment, we should make a reasonable choice. So in the usual use of cold drawing wire and wire, according to their own needs to choose, although the length of the same, but the performance is not the same.

Cold drawing wire is a metal cold processing, with wire rod as raw material, that is, the mouth of the steel bar. Cold drawing wire is a product produced by a series of processes such as shell stripping, which is a common wire. In the development and production of metal materials, cold drawing wire is a very common material, its performance is good, the range of use is very wide, manufacturers in processing are the use of cold processing to produce.

Post time: 07-04-23

Latest articles

-

Under any application environment, users hope that the welding mesh has better strength, as long as it has improved in strength, it will make better use of the demand, but to make the strength of this product improve, also need to have many conditions, to see what kind of data manufacturers have in production, the strength of the product is the strength of the data, But a manufacturer does not meet the strength requirements in the data, and naturally, it cannot make the strength of the product improve after all, so this is the condition.

-

Post time: 06-05-22 -

-

-

Post time: 26-10-22 -

3. Acid activation acid activation solution should be able to remove corrosion products and oxide film (skin) on the surface of parts, without excessive corrosion on the matrix.

Links

Upholstery hand sewing machines are integral to the world of furniture restoration and design. They empower craftsmen to produce high-quality work with precision and creativity while supporting sustainable practices in the industry. Whether you’re a seasoned upholsterer or a novice eager to dive into the world of upholstery, investing in a quality hand sewing machine is a crucial step toward creating beautiful and lasting furniture pieces. In an era that values craftsmanship, individuality, and sustainability, the relevance of upholstery hand sewing machines continues to grow, ensuring that the art of upholstery thrives for generations to come.

Industrial Sewing Machines: These machines are mostly made of high-quality metals and are made to last. They can withstand wear and tear and are made to last for many years under intensive usage.

When it comes to purchase considerations, buyers are often faced with a wide range of options on the market. It is crucial to assess your specific needs before making a decision. For instance, if you plan on doing primarily quilting, you may want to look for a machine that includes a good quilting foot and a wide variety of quilting stitches. On the other hand, if you are focused on garment making or crafting, consider a machine that excels in straight-line sewing and offers various foot attachments for different fabrics.

- The sling sewing machine is a type of sewing machine that is equipped with a sling mechanism that allows the user to operate the machine with one hand. This innovation allows for greater precision and control, making it easier to sew even the most intricate designs. The sling mechanism also allows the user to work at a faster pace, resulting in more garments being produced in a shorter amount of time.

4. Finishing Once you've completed your stitching, trim any excess threads and press the seams gently with an iron. This will enhance the appearance of your work and give a polished finish.

Unlike standard sewing machines, professional upholstery sewing machines possess robust features that cater to heavier materials such as leather, canvas, and thick fabrics. These machines are built to withstand relentless use, ensuring durability and longevity. One of the standout features is their powerful motors, which provide the strong stitching necessary for thick layers of fabric. This capability is essential when working on large furniture pieces, car interiors, or custom projects that require a solid and secure finish.

4. Robust Build Industrial sergers are built for heavy-duty use, often featuring metal components that withstand the rigors of daily operation in a factory. This durability translates to longer lifespans and reduced maintenance needs.

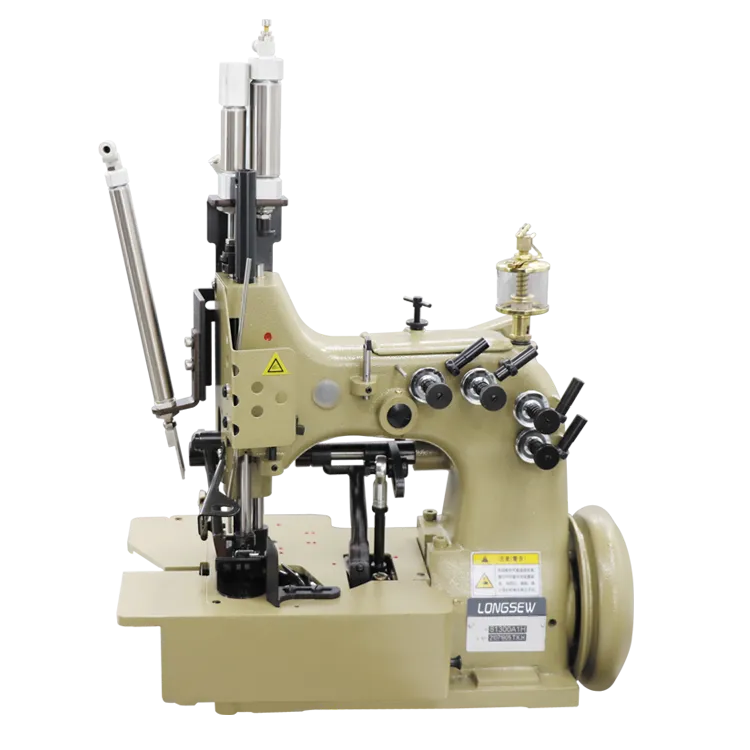

industrial serger machines

2. The main features of the heavy material sewing machine: the heavy material sewing machine adopts the upper and lower composite feeding and the cross-lifting mechanism of the presser foot to ensure that the upper and lower layers do not shift under any stitch length within the rated range, sewing slippery, viscous sewing material and special long products. The products are neat and the stitches are beautiful; the connecting rod thread take-up mechanism increases the spindle speed; the lower feeding shaft adopts sliding bearings, which reduces the noise and prolongs the service life.

One of the key features of GSC367TD is its ability to bind to specific DNA sequences called enhancers or silencers. Enhancers are regions of DNA that enhance the transcription of nearby genes, while silencers inhibit transcription. When GSC367TD binds to an enhancer, it can recruit other proteins that help activate gene transcription. Conversely, when GSC367TD binds to a silencer, it can prevent the transcription of nearby genes.

gsc367td

Sewing thick fabrics like denim, leather, or multiple layers of cotton can be daunting, even for experienced sewists. Standard handheld machines may struggle with heavier materials due to their limited power and construction. However, innovations in this field have led to the creation of specialized handheld sewing machines that can handle thick fabrics efficiently.

Get the best quality sewing machine you can. It can easily last for years and be passed down to a child or grandchild if desired.

2. Enhanced Creativity With a dedicated workspace designed for upholstery, you are more likely to immerse yourself in your projects. A well-organized environment fosters creativity and encourages experimentation with designs and fabrics.

Accessibility for All

In today’s fast-paced industrial environment, efficiency and accuracy are paramount. One of the unsung heroes of modern packaging is the automatic bag closer machine. These machines streamline the process of sealing various types of bags, thereby enhancing productivity and minimizing labor costs. The significance of automatic bag closer machines transcends mere convenience; they are a crucial component in ensuring the quality and integrity of packaged products across diverse industries.

3. Tension Adjustments

Creating Pintucks and Tucks

what is twin needle sewing used for

The Cub Leather Sewing Machine A Tailored Solution for Leather Enthusiasts

Furthermore, manual machines are portable, making them an excellent choice for those who may work in small spaces or wish to take their work on the go. Unlike bulky electric machines that require a reliable power source, a manual sewing machine can be used virtually anywhere, whether in a workshop, at a craft fair, or even outdoors.

Getting Started with Multi-Needle Quilting

Portability is another important aspect to consider. Many units are lightweight and include built-in handles or carrying cases, making it convenient for users who wish to take their sewing projects on the go. This mobility empowers crafters to take their passion to sewing classes, workshops, or even social sewing nights with friends.

Durability and Reliability

4. Cost-Effectiveness While the initial investment in an industrial overlocker may seem significant, the long-term savings in materials, time, and labor can make it a cost-effective solution. Fewer fabric defects result in lower material costs and a reduction in waste.

One of the primary factors influencing the price is the brand reputation. Established brands known for their reliability, durability, and advanced technological features often command higher prices. Manufacturers like Juki, Brother, and Consew are among the leading names in the market, and their machines tend to be more expensive compared to lesser-known brands.

In summary, the straight stitch and zigzag stitch functions of industrial sewing machines are indispensable tools that cater to a wide array of sewing needs. Their combined capabilities allow for efficient production, robust seam integrity, and creative possibilities, making them essential in the textile and fashion industries. As technology continues to evolve, the versatility and efficiency of these stitches will undoubtedly expand, further transforming the ways fabrics are manipulated and created. With their profound impact on productivity and creativity, straight stitch and zigzag stitch functionalities reflect the heart of industrial sewing innovation.

Machine Speed Control

Recycled Materials: In textiles, recycled materials may include repurposed denim, reclaimed leather, or fabrics made from recycled plastics or other sustainable sources, such as old T-shirts made into quilts. Fabrics previously processed or worn can be denser or more difficult to manipulate when crafted with recycled materials, necessitating a heavy-duty sewing machine to ensure efficient and durable needlework.

In summary, the serger machine is a powerful tool that significantly enhances the sewing process. Its ability to finish edges, create durable seams, and deliver a professional quality ensures that it remains an indispensable part of any sewing toolkit. Whether you’re a seasoned designer or a sewing novice, understanding how to utilize a serger machine can elevate your projects and broaden your creative horizons. By incorporating this dynamic machine into your sewing practice, you can achieve superior results and enjoy a more efficient workflow.

Maintenance is another consideration when selecting a sewing machine for both fabric and leather. Leather can leave oils and residues on the machine, necessitating regular cleaning and proper oiling. Heavy-duty machines generally require less frequent maintenance due to their robust construction but keeping an eye on parts like the needle and feed dogs will prolong the life of your machine.

Other popular stitch patterns include straight stitch, decorative stitches, and even embroidery stitches Other popular stitch patterns include straight stitch, decorative stitches, and even embroidery stitches

Other popular stitch patterns include straight stitch, decorative stitches, and even embroidery stitches Other popular stitch patterns include straight stitch, decorative stitches, and even embroidery stitches long arm zig zag sewing machine. This versatility makes the long arm zigzag sewing machine a valuable tool for sewers of all skill levels.

long arm zig zag sewing machine. This versatility makes the long arm zigzag sewing machine a valuable tool for sewers of all skill levels.