barbed wire for garden fence

Latest articles

barbed wire for garden fence

Post time: 22-02-23...

barbed wire for garden fence 【barbed wire for garden fence】

Read More

barbed wire for garden fenceThe iron is clean and clean, and then solvent treatment, after drying immersed in zinc liquid, iron and molten zinc reaction to produce an alloyed zinc layer, the process is: degreasing – washing – pickling – assisted plating – drying – hot dip galvanizing – separation – cooling passivation. The thickness of the alloy layer of hot plating wire mainly depends on the chemical composition of the steel silicon content, the size of the steel cross-sectional area, the roughness of the steel surface, the temperature of the zinc pot, the time of dipping zinc, cooling speed, cold rolling deformation, etc.

...

barbed wire for garden fence 【barbed wire for garden fence】

Read More

barbed wire for garden fenceBlade rope in the world has been widely used in the military, prison, government agencies, banks; Living community wall, private residence, villa wall, doors and Windows, highway, railway guardrail and border line and other protection security.

...

barbed wire for garden fence 【barbed wire for garden fence】

Read More

barbed wire for garden fenceOrdinary blades installed on the walls of the barbed wire fence height in two metres of general construction cost in more than a dozen yuan a metre, but if the prison on the height of the wall construction modest have already reached the four or five meters so that every one meter of the cost of construction in 30-40 yuan, mainly because the work high above the risk is bigger. The construction cost is different, but the price of the blade barbed rope is the same. The construction cost is often higher than the product. In this way, the blade barbed rope factory recommends customers to use the blade barbed rope with better quality to avoid the tedious time and cost of subsequent removal and installation.

...

barbed wire for garden fence 【barbed wire for garden fence】

Read More

barbed wire for garden fenceIf the zinc coating is good, but in 3% nitric acid when the light, the coating has dark shadow, passivation occurs when the film is brown, may be caused by foreign metal impurities such as copper or lead in the galvanizing liquid. When problems occur in the process of galvanizing large coil galvanized wire, the temperature and current density are checked first, and then the content of zinc and sodium hydroxide in the plating solution is measured and adjusted through the analysis of the plating solution. Whether DPE content is low can be determined by hull cell test.

...

barbed wire for garden fence 【barbed wire for garden fence】

Read Morebarbed wire for garden fence

...

barbed wire for garden fence 【barbed wire for garden fence】

Read More

barbed wire for garden fenceIn general, the hardness of a metal is often considered to be the resistance of the material to plastic deformation, scratches, wear, or cutting. In the debugging of zinc wire dipping distance, keep the original speed unchanged, according to the time of dipping zinc, the diameter of steel wire, and then estimate the dipping distance. By adjusting the zinc immersion distance, the zinc immersion time of steel wire of various specifications is shortened by 5s on average compared with that before debugging, so that the zinc consumption per ton of steel wire is reduced from 61kg to 59.4kg.

...

barbed wire for garden fence 【barbed wire for garden fence】

Read MoreCold galvanized wire has good toughness and elasticity, high zinc content can reach 300 g/square meter. It has the characteristics of thick galvanized layer and strong corrosion resistance. Cold galvanized wire is widely used in construction, handicrafts, wire mesh preparation, the production of galvanized hook mesh, wall mesh, highway guardrail, product packaging and daily civilian and other fields.

barbed wire for garden fence...

barbed wire for garden fence 【barbed wire for garden fence】

Read More

barbed wire for garden fenceThe silver powder is actually a mixture of aluminum powder and polymer after painting the film, the film is brittle, easy to appear adhesion problems, and corrosion resistance is also slightly poor. Galvanizing refers to the surface of metal, alloy or other materials coated with a layer of zinc to play the role of beautiful, rust prevention and other surface treatment technology. Zinc dissolves easily in acids and also in bases, so it’s an amphoteric metal. Zinc changes little in dry air.

...

barbed wire for garden fence 【barbed wire for garden fence】

Read Morebarbed wire for garden fence

...

barbed wire for garden fence 【barbed wire for garden fence】

Read More

Popular articles

Latest articles

-

This material itself has the advantages of good integrity, uniform force, high strength, wear resistance, corrosion resistance and so on. Moreover, the production process is simple and the degree of industrialization is high, so its economic benefits are better than other metal mesh materials. In some industrially developed countries, this material has long been used in urban and rural roads, tarmac runway is also widely used. The application of galvanized wire welding net in the construction industry is countless, and the application of galvanized wire welding net in the construction industry has been greatly developed.

-

Relatively speaking, the wire is relatively soft, suitable for binding. Disadvantages are low hardness, low tension, easy to stretch, not suitable for building materials. In different applicable environment, we should make a reasonable choice. So in the usual use of cold drawing wire and wire, according to their own needs to choose, although the length of the same, but the performance is not the same.

-

Most of the production enterprises or large public places, they can play a defense hook mesh in the choice of time, often will hook mesh quality in position, so galvanized hook mesh this product few people are interested in, but does this show that galvanized hook mesh is not useful?

-

-

Because of the high carbon content, simple cracks occur during water quenching, so double liquid quenching (water quenching + oil cooling) is mostly used, and oil quenching is mostly used for small cross section parts. This type of steel is generally used after quenching by medium temperature tempering or normalizing or in the surface quenching state. Mainly used for manufacturing spring and wear-resistant parts.

-

Post time: 21-12-22

Links

In our modern world, where safety and material integrity are paramount, flame retardant tapes have emerged as a crucial component across various industries. These specialized tapes are designed to withstand high temperatures and inhibit the spread of flames, making them an essential tool in improving fire safety and enhancing the durability of materials.

- Flex Tape, a revolutionary product in the world of repair and adhesives, has become a household name due to its exceptional strength and versatility. This 4 x 5 powerhouse is more than just a simple patch; it's a problem-solving tool that can transform the way we approach repairs.

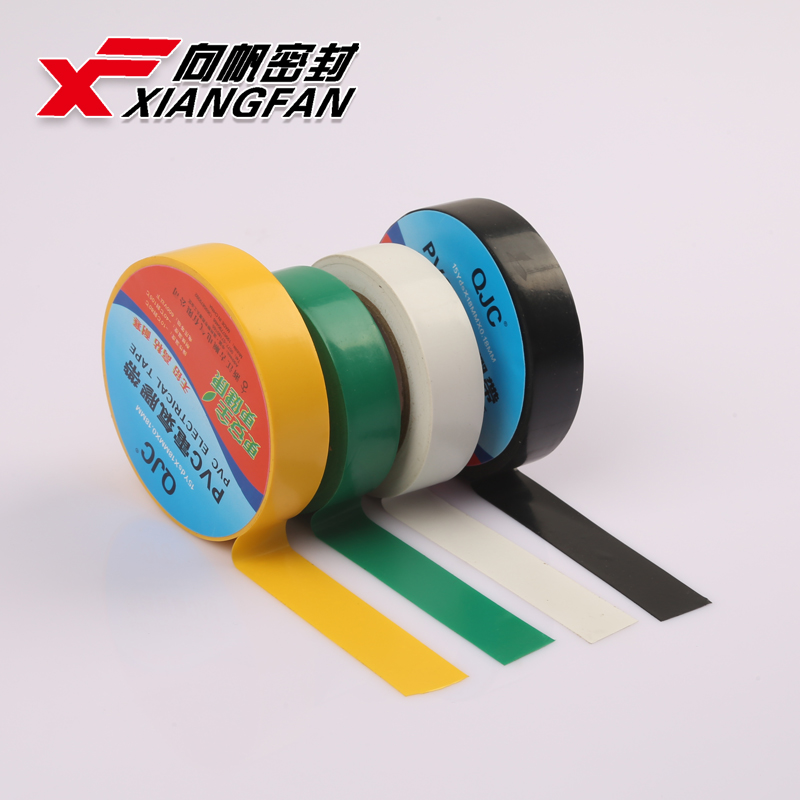

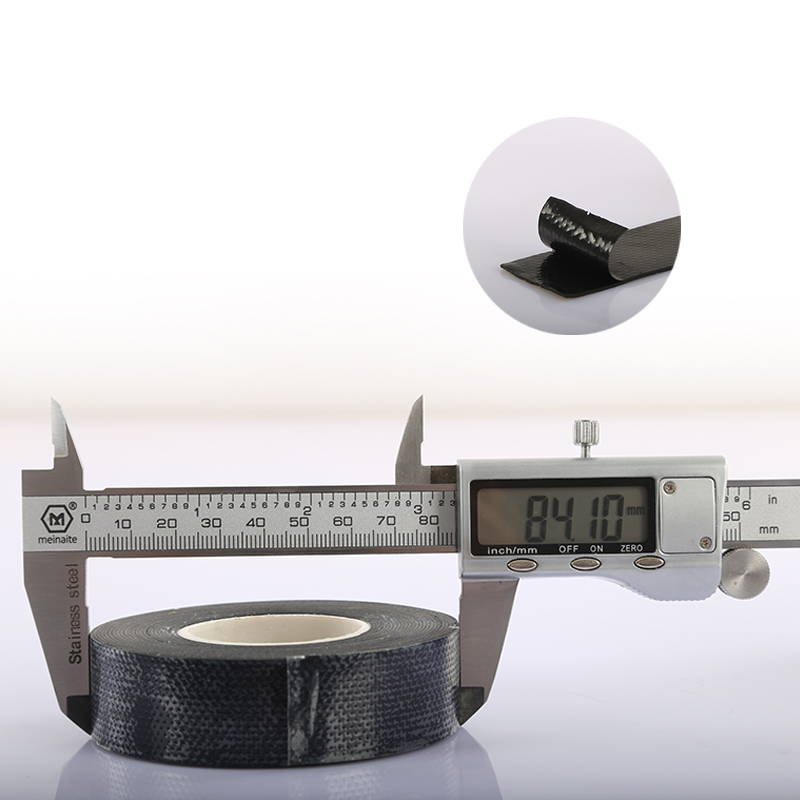

Electrical tape is an adhesive tape that is used specifically for electrical phasing and wiring jobs. Used as a safety measure, electrical tape is applied to any wires or cables which will conduct electricity, to protect and insulate them. Electrical tape is available in different types, depending on the material it is made from, including cloth electrical tape, mastic electrical tape, vinyl electrical tape, rubber electrical tape, and PVC electrical tape.

Understanding Heat Tape An Essential Tool for Electric Applications

(3) The service life is up to 2000 hours at 260 ℃.

Additionally, black PVC electrical tape is available in various widths and thicknesses, allowing users to choose the right type for their specific needs. This customization ensures optimal performance, whether in a simple home repair or a complex electrical installation.

types of intumescent strips. These strips are frequently used in structural applications, such as steel beams and columns, to provide fire protection and structural integrity.

Constant wattage heat tape maintains a consistent heating output regardless of environmental conditions. While it can be more effective in areas with stable temperatures, users must carefully monitor and manage the system to prevent overheating and ensure safety.

Polyethylene Rubber Tape is composed of a polyethylene backing material with a rubber-based adhesive. Polyethylene is a thermoplastic polymer known for its excellent resistance to moisture, chemicals, and abrasion. The rubber adhesive provides strong adhesion to different surfaces.

The benefits of using fire seal tape extend beyond mere compliance. Properly installed fire seal tape contributes to the overall efficiency of a building’s HVAC system by preventing air leaks. This can result in lower energy costs, as the heating and cooling systems do not have to work as hard to maintain desired temperatures.

Processing Unit

Applications of Heat Tape

yellow warehouse floor tape. Unlike paint, which can be messy and time-consuming to apply, tape can be easily installed and removed as needed. This makes it a flexible option for businesses that may need to modify their floor markings frequently.

self amalgamating electrical tape. It can withstand temperatures ranging from -65°F to 220°F, making it ideal for use in harsh environments. Its waterproof properties also make it a great choice for outdoor electrical repairs, as it can protect against rain and other weather conditions.

self amalgamating electrical tape. It can withstand temperatures ranging from -65°F to 220°F, making it ideal for use in harsh environments. Its waterproof properties also make it a great choice for outdoor electrical repairs, as it can protect against rain and other weather conditions.