bronze screen

Latest articles

bronze screen

Post time: 16-09-22...

bronze screen 【bronze screen】

Read Morebronze screen

...

bronze screen 【bronze screen】

Read More

bronze screenThe distance between the adjacent two thorn rope installation do not know whether you have noticed? Careful observation can find that its spacing is not the same, the thorn rope factory for customer consultation when asking the installation height of the reason.

...

bronze screen 【bronze screen】

Read Morebronze screen

...

bronze screen 【bronze screen】

Read MoreCan adapt to the change of the slope without being damaged, than the rigid structure has a very good safety and stability;

bronze screen...

bronze screen 【bronze screen】

Read Morebronze screen

...

bronze screen 【bronze screen】

Read Morebronze screen

...

bronze screen 【bronze screen】

Read Morebronze screen

...

bronze screen 【bronze screen】

Read Morebronze screen

...

bronze screen 【bronze screen】

Read More

bronze screenHot wire is made of high quality low carbon steel, high carbon steel, after drawing, hot galvanized processing galvanized wire. Hot dip galvanized wire production process: wire rod – drawing – annealing – drawing – annealing – galvanized. Hot dip galvanized wire has the characteristics of thick coating, strong corrosion resistance and solid coating. And according to the special needs of users, according to the industry standard to provide various specifications of galvanized wire. Hot-dip galvanized wire is of better quality than electrodip galvanized wire. In the production process, hot dip galvanized wire has more than one annealing process, so the corrosion resistance of hot dip galvanized wire is stronger than that of electric galvanized wire.

...

bronze screen 【bronze screen】

Read More

Popular articles

- Pure zinc is more stable in dry air. In moist air or water containing carbon dioxide and oxygen, the surface will generate a layer of basic zinc carbonate based thin film layer, which can delay the corrosion rate of zinc layer. Comparison of corrosion resistance of zinc coating in aqueous solution of acid, alkali and sodium chloride; It is also resistant to corrosion in atmospheres containing carbon dioxide and hydrogen sulfide and in oceanic atmospheres; In high temperature and high humidity air and contain organic acid atmosphere is small, galvanized layer is also easy to be corroded.

Cold galvanizing is in the plating tank through the current unidirectional zinc gradually plated on the metal appearance, the production speed is slow, uniform coating, thin thickness, usually only 3-15 microns, bright appearance, smooth, high aesthetics, poor corrosion resistance, generally a few months will rust. Hot dip galvanized coating is thicker, generally 30-60 microns, coating corrosion resistance is higher. Suitable for outdoor work of steel parts, such as highway fences, power towers, large size fasteners and other more “rough” workpiece long-term rust prevention.

And high quality data and production cost and production conditions are bound, so some welding screen manufacturers did not meet the requirements of this aspect, natural in this case there is no way to improve product strength. In addition to data, and produce process, even if again good data, but the factory did not meet the requirements of production process in welding, also can form the product under the high pressure welding, so it is also a kind of strength on the decline, process conditions of different manufacturers also have very big difference, so it formed a shopping mall on the above products are differences of strength.

- D, coating adhesion; The zinc layer of the plating parts should be firmly combined with the base metal with sufficient adhesion strength, and will not fall off or bulge after the hammer test.

The anticorrosion of these raw materials is very different, and the use of life is not the same. Niu LAN net cold galvanized, also known as electroplating, galvanized quantity is very little, rust in rain, but the price is cheap, the use of life in 5-6 years. Hot dip galvanizing (low zinc and high zinc) on the amount of zinc in 60 grams to 400 grams, the service life is about 20-60 years, corrosion resistance is general.

- Five: Spray blade thorn rope specifications: BTO-10, BTO-12, BTO-18, BTO-22, BTO-28, BTO-30, CBT-60, CBT-65

Latest articles

-

Post time: 26-04-23 -

-

-

(4) can withstand a large range of deformation, but still do not collapse. Play the role of fixed thermal insulation;

-

Some customers may not use the blade rope immediately when they buy it, some are retail, and some are temporarily not used in site construction. At this time, it is necessary for customers to follow up the characteristics of the blade rope for storage. Because they are afraid of rain, so this is needless to say, and the surface of the packaging is more afraid of the sun, so it is not recommended to prevent outdoor exposure to sunlight will cause the woven bag to become ineffective, resulting in the internal blade of the rope exposed to affect the later use.

-

Links

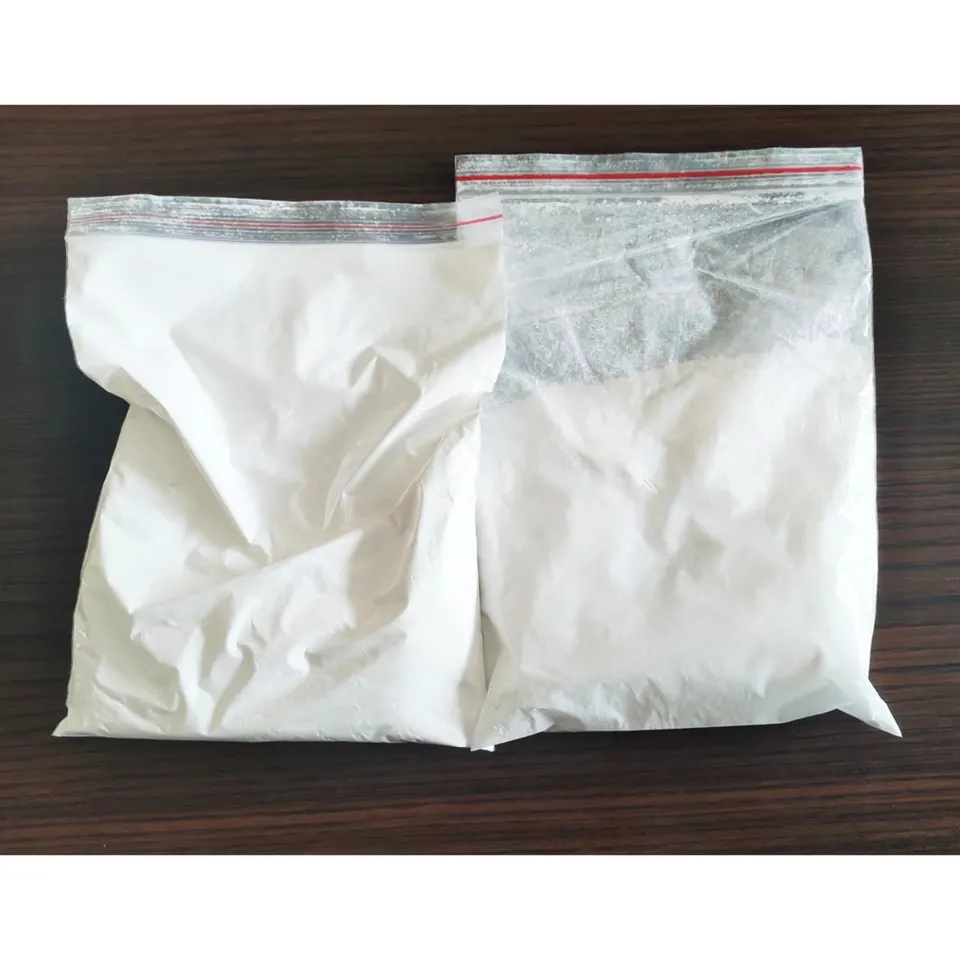

In conclusion, the demand for dyes and pigments is on the rise, and having a reliable titanium dioxide factory like CAS 13463-67-7 is essential for meeting this demand. With its dedication to quality, sustainability, and innovation, CAS 13463-67-7 is well-positioned to continue serving the needs of its customers and the industry as a whole.

- Tiona, a prominent name in the world of titanium dioxide manufacturing, has established itself as a frontrunner in the industry. With its commitment to excellence and innovation, Tiona has become a trusted partner for companies seeking high-quality titanium dioxide products.

- As the demand for anatase products continues to grow, the number of factories specializing in their production is also expected to increase. Furthermore, ongoing research and development efforts are aimed at improving the performance and functionality of anatase products, expanding their applications and making them more accessible to a wider range of industries.

Titanium dioxide is produced at pigment grade or nano grade.

This combination is particularly popular in foundations, concealers, and powders, where it is used to create a flawless and long-lasting base This combination is particularly popular in foundations, concealers, and powders, where it is used to create a flawless and long-lasting base

This combination is particularly popular in foundations, concealers, and powders, where it is used to create a flawless and long-lasting base This combination is particularly popular in foundations, concealers, and powders, where it is used to create a flawless and long-lasting base dimethicone titanium dioxide manufacturers.

dimethicone titanium dioxide manufacturers.

lithopone 28-30% factory.

coating titanium dioxide suppliers. Service Good communication and customer service are essential when working with a coating titanium dioxide supplier. Look for a supplier that is responsive, knowledgeable, and willing to work with you to find the best solution for your needs.

coating titanium dioxide suppliers. Service Good communication and customer service are essential when working with a coating titanium dioxide supplier. Look for a supplier that is responsive, knowledgeable, and willing to work with you to find the best solution for your needs.When E171 is part of a food product, it passes through the digestive system without causing harm because E171 combines with the other ingredients.

It can split water molecules or decompose organic compounds when exposed to light, which is a promising feature for environmental clean-up operations and renewable energy initiatives It can split water molecules or decompose organic compounds when exposed to light, which is a promising feature for environmental clean-up operations and renewable energy initiatives

It can split water molecules or decompose organic compounds when exposed to light, which is a promising feature for environmental clean-up operations and renewable energy initiatives It can split water molecules or decompose organic compounds when exposed to light, which is a promising feature for environmental clean-up operations and renewable energy initiatives r 5566 titanium dioxide. Furthermore, when titanium dioxide nanoparticles are incorporated into cement or concrete, they can endow self-cleaning properties to architectural surfaces by promoting the breakdown of pollutants like nitrogen oxides under UV light.

r 5566 titanium dioxide. Furthermore, when titanium dioxide nanoparticles are incorporated into cement or concrete, they can endow self-cleaning properties to architectural surfaces by promoting the breakdown of pollutants like nitrogen oxides under UV light.

Another important factor to consider when choosing r 996 titanium dioxide suppliers is their reliability and consistency in supply

. Having a supplier that can consistently deliver the required quantities of the product on time is crucial for maintaining smooth operations in various industries. r 996 titanium dioxide suppliers have built a reputation for their reliability and timely delivery of products, making them a preferred choice for many businesses.r 996 titanium dioxide suppliers

How to Approach Titanium Dioxide in Products

Key Points/Overview

Its high refractive index allows it to scatter light effectively, resulting in brighter colors and improved opacity Its high refractive index allows it to scatter light effectively, resulting in brighter colors and improved opacity

Its high refractive index allows it to scatter light effectively, resulting in brighter colors and improved opacity Its high refractive index allows it to scatter light effectively, resulting in brighter colors and improved opacity tr 28 titanium dioxide manufacturer. This makes it a valuable ingredient in products where color and appearance are important.

tr 28 titanium dioxide manufacturer. This makes it a valuable ingredient in products where color and appearance are important.After oral ingestion, the absorption of titanium dioxide particles is low, however they can accumulate in the body, Maged Younes, chair of the European Food Safety Authority's expert Panel on Food Additives and Flavourings, said in a May 2021 statement.

The mineral appears to have low skin penetration, but it is a greater concern when inhaled frequently over time.

Inflammation of the intestines

Titanium alloy is widely used as a biomaterial due to its superior biocompatibility, mechanical properties close to human bones, and enhanced corrosion resistance. These properties have made the alloys suitable for use in a wide spectrum of biomedical applications including artificial bones, artificial joints, dental roots, and medical devices. The excellent performance of titanium alloy is mainly due to the oxide film as shown in Figure 1 [1]. The functional composition of the oxide film is mainly titanium dioxide (TiO2). Titanium dioxide has good biocompatibility, stable chemical property, and low solubility in water, which prevents substrate metal ions from dissolution. Furthermore, it also improves the wear and fatigue resistance of implants in the human body.

By incorporating titanium dioxide into dyes, manufacturers can achieve a wider range of colors and shades, as well as ensure that the colors remain bright and fade-resistant even after repeated washing or exposure to sunlight By incorporating titanium dioxide into dyes, manufacturers can achieve a wider range of colors and shades, as well as ensure that the colors remain bright and fade-resistant even after repeated washing or exposure to sunlight

By incorporating titanium dioxide into dyes, manufacturers can achieve a wider range of colors and shades, as well as ensure that the colors remain bright and fade-resistant even after repeated washing or exposure to sunlight By incorporating titanium dioxide into dyes, manufacturers can achieve a wider range of colors and shades, as well as ensure that the colors remain bright and fade-resistant even after repeated washing or exposure to sunlight plastic and dyeing used titanium dioxide r218 factory. R218 factory produces titanium dioxide that is specifically designed for use in dyes, allowing textile manufacturers to create high-quality, colorfast materials for a variety of applications.

plastic and dyeing used titanium dioxide r218 factory. R218 factory produces titanium dioxide that is specifically designed for use in dyes, allowing textile manufacturers to create high-quality, colorfast materials for a variety of applications.