perforated sheet metal stainless

Latest articles

perforated sheet metal stainlessSelect cut wire first of all to ensure that the raw material of the silk is exactly the raw material you need, the raw material to ensure that it will be used well. Choose the straightness is relatively high, so that the length of the truncation will be the same, there will not be a lot of length difference, the length of the truncated wire is a very important element to select the truncated wire.

...

perforated sheet metal stainless 【perforated sheet metal stainless】

Read MoreBecause of the pre-tension given to the packaging and binding of galvanized wire, it has the excellent characteristics of low relaxation value, small stress loss, good stability after loading, not easy to deformation, no fracture, strong elasticity, ordinary steel lines and rebar are difficult to compare. The use of advanced galvanized finishing process, therefore, the use of hot-dip galvanized steel wire construction, not only good corrosion resistance, but also beautiful and generous. The product has the characteristics of smooth surface, high dimensional accuracy, good uniformity of zinc layer and strong adhesion.

perforated sheet metal stainless...

perforated sheet metal stainless 【perforated sheet metal stainless】

Read More

perforated sheet metal stainlessNo matter how old dogs are, they seem to love to touch noses with people and other animals. In fact, dogs touch noses as a way of socializing, just like humans shake hands and hug when they meet. But dogs don’t nuzzle every human or every animal. They pick and choose who to nuzzle. If they don’t like you, or don’t know you at all, they won’t touch your nose. However, adult dogs will touch almost every puppy’s nose, and they will not only touch the puppy’s nose, but also smell the puppy’s body.

...

perforated sheet metal stainless 【perforated sheet metal stainless】

Read Moreperforated sheet metal stainless

...

perforated sheet metal stainless 【perforated sheet metal stainless】

Read More

perforated sheet metal stainless

Post time: 23-12-22...

perforated sheet metal stainless 【perforated sheet metal stainless】

Read More

perforated sheet metal stainless

Post time: 14-02-23...

perforated sheet metal stainless 【perforated sheet metal stainless】

Read MoreTo stop normalizing or soxhlet processing of wire rod, spheroidization annealing is used instead of large specification. In the middle, especially before the waste drawing process, the thermal disposal of soxhlet is widely used. Prevent decarbonization during thermal disposal. After hot disposal, sulfuric acid or hydrochloric acid pickling is used to remove the iron sheet. Coating can be used to dip lime, phosphating, borax treatment or copper plating.

perforated sheet metal stainless...

perforated sheet metal stainless 【perforated sheet metal stainless】

Read Moreperforated sheet metal stainless

...

perforated sheet metal stainless 【perforated sheet metal stainless】

Read Moreperforated sheet metal stainless

...

perforated sheet metal stainless 【perforated sheet metal stainless】

Read More

perforated sheet metal stainlessWire factory introduction annealing wire is widely used mainly because it has good elasticity and flexibility, in the process of annealing can be very good control of its soft and hard degree, it is mainly made of iron wire, more often used in the construction industry tied wire use. In the production of annealing wire will be processed according to the performance of the material, according to the demand for different degree of hardness of its soft change, can make it has more advantages, can reduce the consumption of metal, reduce the cost of production.

...

perforated sheet metal stainless 【perforated sheet metal stainless】

Read More

Popular articles

- The uniformity of galvanized wire is reflected in what aspects:

- Choose a cage that can stand up straight in order to keep your dog comfortable. Lay down with your feet out wide. The dog, can save much, can buy a small cage, can also see it as the same as people, give it a bigger cage, so that it can use half to activity, half to sleep. Use an old blanket for your dog’s crate, or buy a pet mat, as long as it’s comfortable.

The derusting steel parts are immersed in the melted zinc liquid at about 500℃, so that the surface of the steel member is attached with zinc layer, so as to achieve the purpose of anti-corrosion. The surface of galvanized wire coating can see whether the quality of galvanized wire is good or not. If the strength of zinc attached to the wire is very poor, then this galvanized wire do not buy, because this galvanized wire must be poor galvanized wire.

- Cages are more often used to contain large dogs, which have a lot of strength. So the choice of dog cage must be strong, otherwise the dog is easy to break out of the dog cage.

Latest articles

-

-

If the zinc coating is good, but in 3% nitric acid when the light, the coating has dark shadow, passivation occurs when the film is brown, may be caused by foreign metal impurities such as copper or lead in the galvanizing liquid. When problems occur in the process of galvanizing large coil galvanized wire, the temperature and current density are checked first, and then the content of zinc and sodium hydroxide in the plating solution is measured and adjusted through the analysis of the plating solution. Whether DPE content is low can be determined by hull cell test.

-

-

-

-

Links

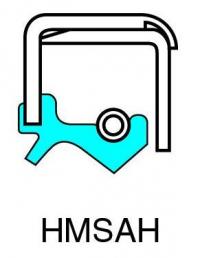

In conclusion, oil seals play a critical role in high-pressure systems by preventing leaks and maintaining the integrity of the machinery. With proper design, materials, and maintenance, high-pressure oil seals can withstand the extreme pressures and harsh conditions commonly found in industrial settings. By investing in quality seals and regular maintenance, operators can ensure the reliability and efficiency of their high-pressure systems for years to come.

- Enhancing Engine Efficiency with Performance Spark Plugs A Comprehensive Overview

Maintenance and Replacement of Valve Cover Gaskets

- In conclusion, the GY6 spark plug is a critical component of any scooter or motorcycle equipped with this popular engine. By delivering a strong and consistent spark, the spark plug ignites the air-fuel mixture in the combustion chamber, powering the engine and propelling the vehicle forward. Choosing the right spark plug and maintaining it properly are essential steps to ensure optimal engine performance and longevity. Keep your GY6 engine running smoothly by giving your spark plug the attention it deserves.

⑥

Does it mean the seal stops the leakage completely? Well, on the practical grounds yes because there is no ‘visible leakage’.

Rotary Wheel Of Auto Parts

Significance of Valve Cover Gaskets and Head Gaskets

The benefits of silicone include:

The head gasket and valve cover gasket are critical components in the engine's sealing system. The head gasket seals the cylinder head to the engine block, while the valve cover gasket seals the valve cover to the cylinder head. Both gaskets play pivotal roles in maintaining the integrity and functionality of the engine, preventing oil leaks and ensuring the proper sealing of the combustion chamber.