vibrating wire mesh screen

Latest articles

vibrating wire mesh screen

...

vibrating wire mesh screen 【vibrating wire mesh screen】

Read MoreMost cattle nets are mechanically woven from high ductility and corrosion resistance of low carbon steel wire or PVC clad steel wire. Several common materials used in the manufacture of cattle nets are electrogalvanized wire, hot-dip galvanized wire, Galfan plated steel wire, 10 percent aluminum zinc alloy steel wire and the new selenium chromium plated steel wire.

vibrating wire mesh screen...

vibrating wire mesh screen 【vibrating wire mesh screen】

Read Morevibrating wire mesh screen

...

vibrating wire mesh screen 【vibrating wire mesh screen】

Read More

vibrating wire mesh screen

Post time: 08-05-23...

vibrating wire mesh screen 【vibrating wire mesh screen】

Read Morevibrating wire mesh screen

...

vibrating wire mesh screen 【vibrating wire mesh screen】

Read Morevibrating wire mesh screen

...

vibrating wire mesh screen 【vibrating wire mesh screen】

Read Morevibrating wire mesh screen

...

vibrating wire mesh screen 【vibrating wire mesh screen】

Read MoreGreat attention should be paid to pickling of large rolls of galvanized wire. Acid is highly corrosive. Therefore, when adding acid, the acid must be poured into the water, and it is along the wall of the cylinder, and not thrown down at once, so as not to cause splashing. Remember the order of acid pouring, acid into water rather than water into acid, water into acid will cause splashing and boiling, when pouring acid must wear protective glasses, beside must ensure that there are no non-professional people watching, so as not to cause some acid splashing danger.

vibrating wire mesh screen...

vibrating wire mesh screen 【vibrating wire mesh screen】

Read More

vibrating wire mesh screenWire mesh welding after galvanized is through the end of the welding and then the cold company to make wire mesh wire mesh steel mesh construction mesh floor heating mesh galvanized or hot galvanized. After the first galvanized welding is to change the wire mesh, after the end of welding can see the welding spot; The two processes are different prices are also very different, the cost of the first plating after welding is low, the appearance is smooth, and the cost of the first welding after plating is higher, not easy to rust.

...

vibrating wire mesh screen 【vibrating wire mesh screen】

Read MoreDark green plastic-coated barbed cords are occasionally used on high-speed trains, but they are also used in small quantities.

vibrating wire mesh screen...

vibrating wire mesh screen 【vibrating wire mesh screen】

Read More

Popular articles

Large hexagonal mesh called stone cage net, is mainly used for mountain protection, hydraulic construction and so on. Small wire hexagonal mesh is used as a good material for breeding, will twist twist hexagonal mesh in the welded iron frame on the hexagonal mesh welding into chicken coop, pigeon cage, rabbit cage cage cage, hexagonal mesh is the best material for breeding with a net.

Galvanized iron wire is selected from excellent low carbon steel, through drawing forming, pickling rust removal, high temperature annealing, hot dip galvanized, cooling and other processes. Galvanized iron wire should pay attention to the following points in the use process:

Hexagonal net value is quite high in landslides, many slope through the baptism of the rain after this, there may occur sediment flow of plague and as a result some losses to the property of the people, have the existence of hexagonal wire netting, can solve this problem, from the fundamental up sediment flow in came it can help guard against protection, achieve low is the loss of many people.

- Of course, the quality of any kind of product is also affected by the implementation of the specification by the manufacturer. If the manufacturer of electric welding mesh has no high implementation specification in the production itself, or the procedure specification has declined in the production line, or there is no higher requirement on the production link.

Latest articles

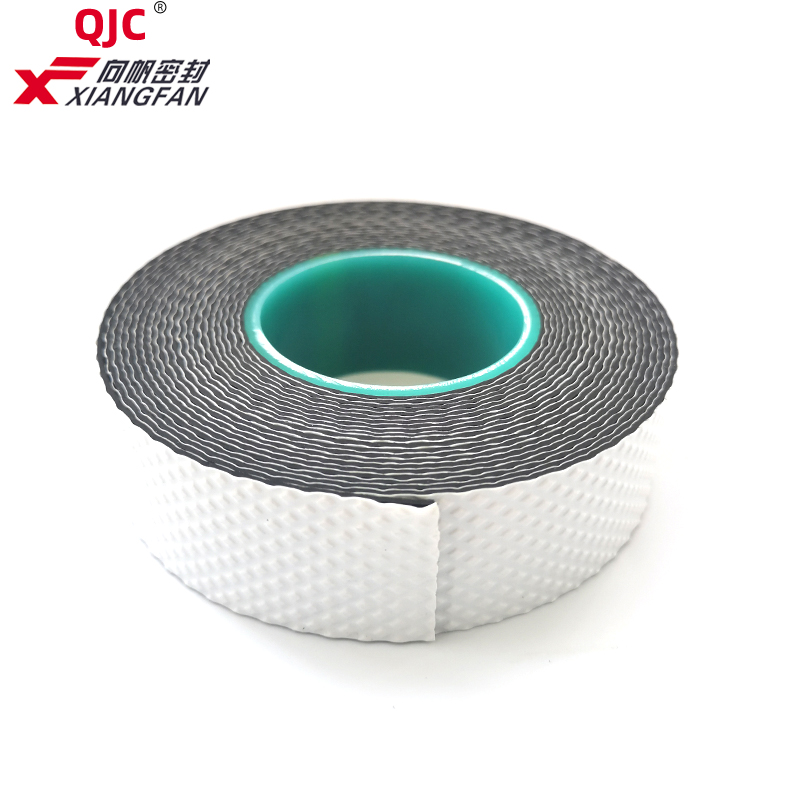

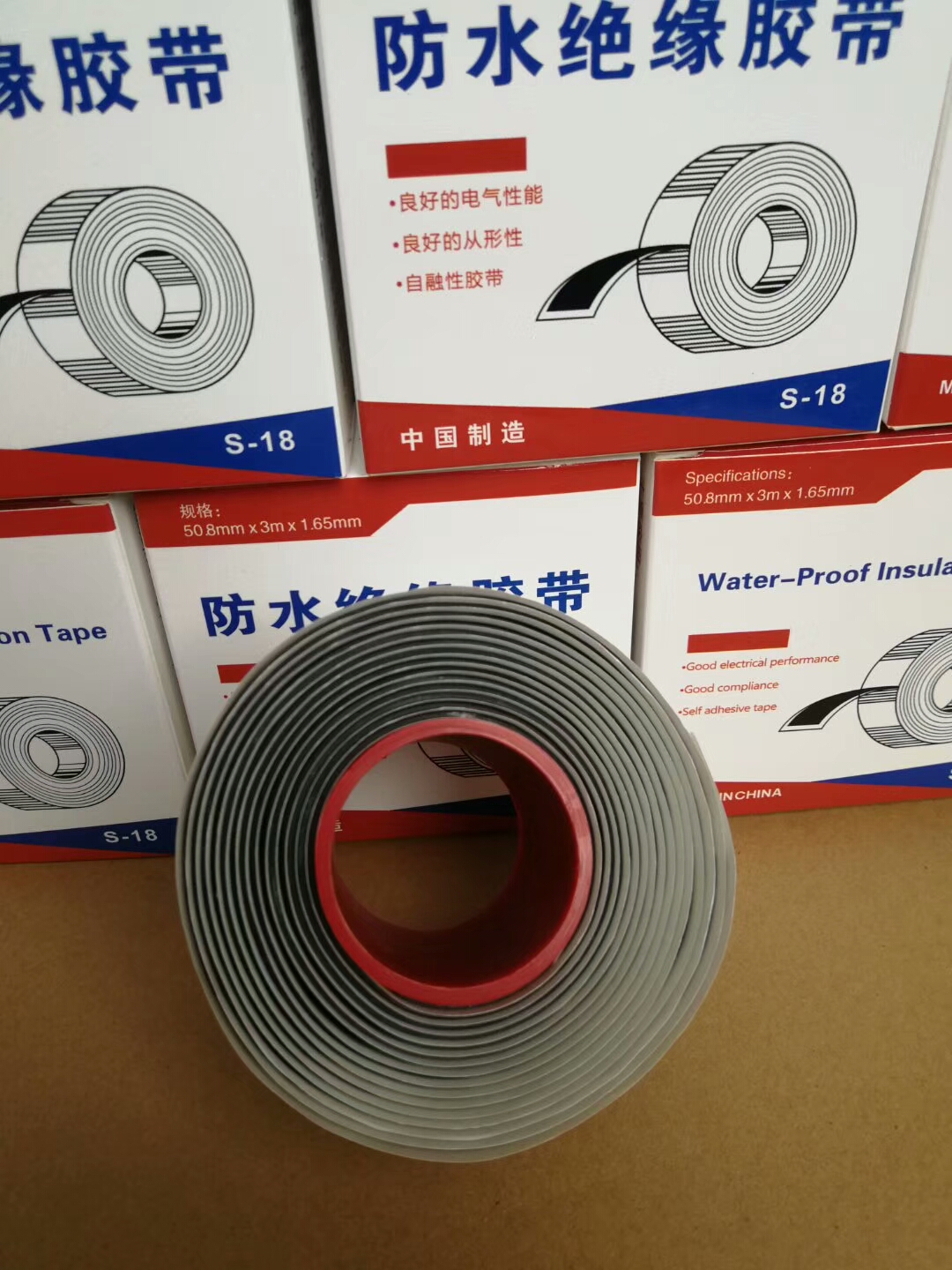

Uses for self-amalgamating tape

Conclusion

durable floor tape. Most tapes are self-adhesive, which means they can be applied quickly and easily without the need for any special tools or equipment. This makes it a cost-effective solution for businesses that need to regularly update their floor markings.

durable floor tape. Most tapes are self-adhesive, which means they can be applied quickly and easily without the need for any special tools or equipment. This makes it a cost-effective solution for businesses that need to regularly update their floor markings.The function of moisture-sealing tapes such as vinyl, rubber, and mastic products is to exclude moisture from the insulation assembly and provide electrical insulation. One of these tapes — or alternately a mastic pad — generally forms the second layer of the insulation assembly. Rubber, mastic, and filler tapes are also used to pad the underlying surface by covering sharp edges.

The 4 x 5 size of Flex Tape Black is particularly advantageous. The width provides a broad surface area for applications, allowing you to cover larger gaps or tears with just one piece. This is particularly useful for quick fixes around the house, from sealing leaks in pipes or roofs to fixing torn screens or tarps.

High quality self fusing silicone tape for demanding applications and long term performance. 3M 70 is grey, withstands elevated temperatures and has good UV resistance.

diall self fusing tape. Its high dielectric strength makes it safe to use on electrical components, providing an extra layer of protection against shorts and sparks. The flexibility of the tape allows for easy wrapping around irregular shapes and surfaces.

It is used for making watertight seals, waterproofing joints, and temporarily repairing leaks in pipes, hoses and tubes.

Self-adhesive insulation tape is a remarkable product that has gained significant popularity across various industries and DIY projects. This versatile tape offers a myriad of applications, ranging from electrical insulation to home improvement, making it an essential item in both professional and personal toolkits.

Rubber Repair Tape, on the other hand, is specifically engineered for various repair applications. It boasts a composition tailored for durability and flexibility, making it a top choice for a range of repair scenarios.rubber repair tape is a reliable solution known for its ability to handle a multitude of repair tasks with ease.

rubber tape to stop water leaks. It is commonly used to repair plumbing pipes, seal windows and doors, and patch up holes and cracks in walls. Its versatility and ease of use make it a must-have item for any DIY enthusiast or homeowner.

splicing tape use. This ensures a smooth and consistent print job without any breaks or interruptions. Similarly, in the packaging industry, splicing tape is used to join the ends of rolls of film or other packaging materials to create a continuous stream for packaging machines to work efficiently.

6. Energy Efficiency Many butyl rubber roofing sheets come with reflective properties, which can help in reducing heat absorption. This characteristic contributes to the overall energy efficiency of buildings, making them cooler and potentially lowering air conditioning costs.

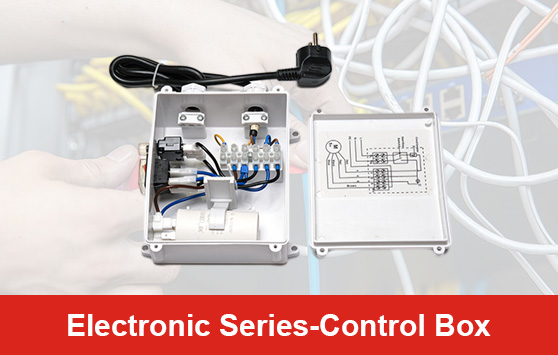

These specialized control boxes are primarily deployed in business buildings and their primary role is to manage air conditioning systems and lighting. They are relatively more complex than residential control boxes but their strength cannot be equated to that of industrial boxes.

Rubber tapes are an essential component in many industries, including construction, automotive, and electrical fields. These tapes are made from different types of rubber and used for various applications, such as sealing, insulation, and packaging. Here are some of the most commonly used rubber tapes:

1. Silicone Rubber Tape: This type of rubber tape is highly resistant to heat, cold, and moisture, which makes it ideal for electrical and electronic applications. It can also be used for sealing and insulating.

2. Butyl Rubber Tape: Butyl rubber tape is known for its high adhesive strength and excellent sealing properties. It is often used in the construction industry for sealing roofs, windows, and doors.

3. EPDM Rubber Tape: EPDM (ethylene propylene diene monomer) rubber tape is highly resistant to UV radiation and weathering, which makes it ideal for outdoor applications. It is often used for sealing or protecting joints, roofs, and facades.