soft annealed wire

Latest articles

soft annealed wire

...

soft annealed wire 【soft annealed wire】

Read More

soft annealed wireCold galvanized wire refers to a process in which ordinary steel wire is treated by cold galvanized and a zinc layer is attached to its surface. Cold galvanized wire has the advantages of anti-corrosion and anti-wear, and is widely used in construction, machinery, automobile, electronics and other industries. The following will introduce the production process and flow of cold galvanized wire.

...

soft annealed wire 【soft annealed wire】

Read More2. Breeding small animals such as chickens, ducks and geese, enclosure protection for fruit trees and gardens, and protection for medium-sized breeding, it is recommended that you choose products with a wire diameter of 2.3mm-2.5mm.

soft annealed wire...

soft annealed wire 【soft annealed wire】

Read Moresoft annealed wire

...

soft annealed wire 【soft annealed wire】

Read More

soft annealed wireLow and medium carbon steel wire is used as raw material, with good surface gloss, uniform zinc layer, strong adhesion, corrosion resistance and so on. Available: diameter 1.60mm-4mm (16#-33#) cold plating wire; Diameter 6.40mm-0.81mm(8#-21#) black iron wire, changed wire. It is mainly used in communication equipment, medical equipment, weaving net, brush, steel cable, filter, high-pressure pipe, construction, crafts and other industries.

...

soft annealed wire 【soft annealed wire】

Read More

soft annealed wireGalvanized wire coating rough, passivation film is not bright, bath temperature is too high. If the cathode current density is too high, zinc content in the bath is too high or sodium hydroxide and DPE content is too low; Solid particles or excessive foreign metal impurities in the electroplating solution can cause such problems. Solution: If the coating of large galvanized wire is rough, there may be solid particles in the plating solution. If the roughness of the part is severe, the current density may be too high.

...

soft annealed wire 【soft annealed wire】

Read More

soft annealed wire2. Adjust the drawing process parameters of the water tank

...

soft annealed wire 【soft annealed wire】

Read Moresoft annealed wire

...

soft annealed wire 【soft annealed wire】

Read More

soft annealed wire

Post time: 02-06-22...

soft annealed wire 【soft annealed wire】

Read Moresoft annealed wire

...

soft annealed wire 【soft annealed wire】

Read More

Popular articles

Latest articles

-

-

The protective duration of galvanized iron wire is closely related to the thickness of galvanized iron wire. In general, zinc layer thickness needs to be very high in dry main gas and indoor applications, but in harsh environments. Therefore, in the selection of galvanized layer thickness, the impact of the environment should be considered. If galvanized iron wire products of different diameters are required, material selection and coating should be controlled reasonably.

-

The life of the “wire”, is actually “low carbon steel wire”, carbon content in less than 0.2%. The surface is usually coated with zinc plating because it is easy to rust. Under atmospheric conditions, the galvanized layer will not rust before most of the fall off, relatively soft. The life of the “steel wire”, is carbon content in about 0.6% of the “carbon steel wire”, or carbon content in about 0.8% of the “high carbon steel wire”, they have enough hardness and elasticity after appropriate heat treatment, high strength. Uses such as winding ordinary spring and so on.

-

-

-

Links

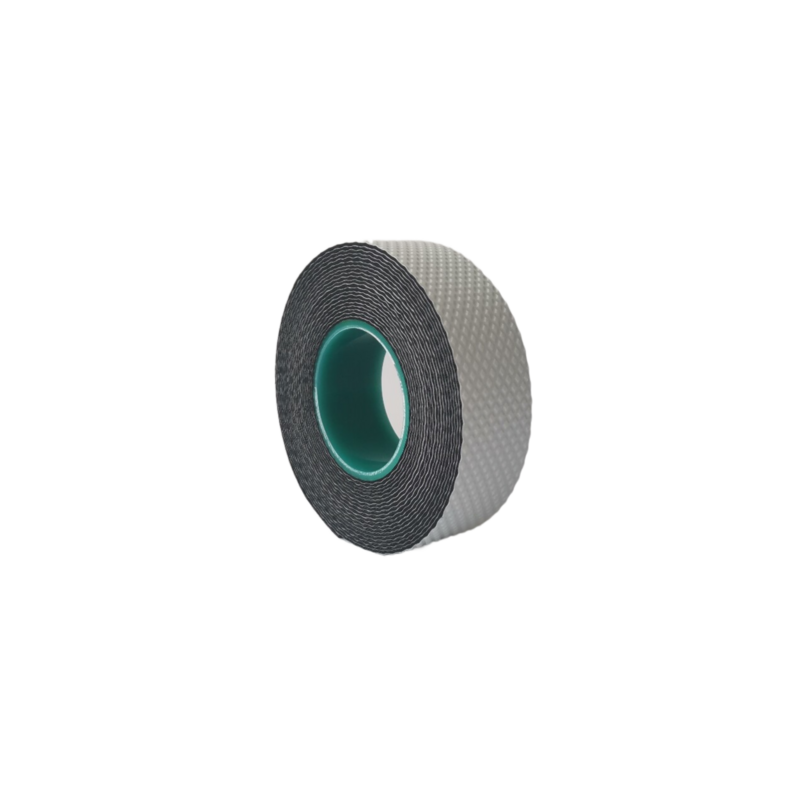

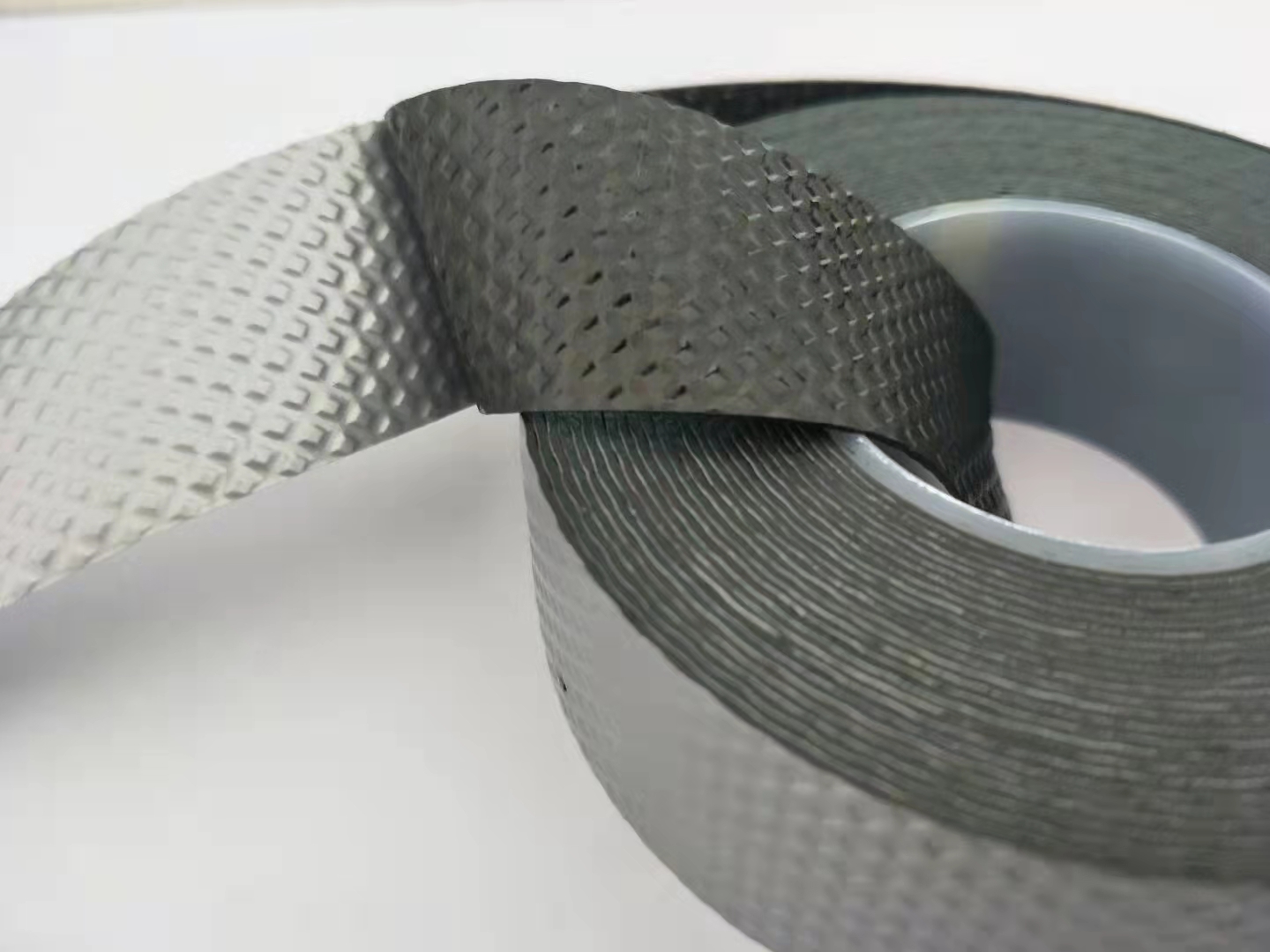

Familiarize yourself with your area’s building codes. Select tapes that have been meticulously tested for reliability to ensure you’re getting tools that are worthy of your investment. It’s a good idea to opt for these tapes, too, as they are most likely to comply with building code.

- Another common use of varnished cambric tape is in the construction industry. It can be used to protect pipes and other materials from corrosion and damage. The tape is also flame resistant, making it a safe choice for use in construction projects where fire safety is a concern.

- In conclusion, Flex Tape is a highly effective and versatile product that can be used for a wide range of repairs and projects. Its strong adhesive, waterproof design, and flexibility make it a valuable tool for anyone in need of a quick and reliable fix. Whether you are repairing a leaky pipe, patching up a torn awning, or securing a loose cable, Flex Tape is sure to get the job done.

In the automotive sector, it's used for wire harnessing and general repair work In the automotive sector, it's used for wire harnessing and general repair work

In the automotive sector, it's used for wire harnessing and general repair work In the automotive sector, it's used for wire harnessing and general repair work