perforated fiberglass sheets

Latest articles

perforated fiberglass sheets

...

perforated fiberglass sheets 【perforated fiberglass sheets】

Read Moreperforated fiberglass sheets

...

perforated fiberglass sheets 【perforated fiberglass sheets】

Read Moreperforated fiberglass sheets

...

perforated fiberglass sheets 【perforated fiberglass sheets】

Read More

perforated fiberglass sheetsUse in daily life does not need to carry out maintenance and maintenance, save a lot of time, but also save maintenance and maintenance costs. The annealed wire has good stability and corrosion resistance, which greatly prolongs its service life. There are many kinds, which can be selected according to different uses. The device for making anneal wire is simple, which improves the utilization rate of the device. The material properties of annealed wire can meet different processing requirements.

...

perforated fiberglass sheets 【perforated fiberglass sheets】

Read More

perforated fiberglass sheetsOrdinary installation of blade thorn rope on the wall and the height of the wall in two meters up and down the general construction costs in a dozen yuan a meter, but if it is said that the height of the prison construction ordinary wall has reached four or five meters so that the construction cost of each meter is about 30 or 40 yuan, mainly because of high altitude operation risk degree is relatively large reason. The construction cost is different, but the price of blade thorn rope is the same, often the construction cost is higher than the product, which is the thorn rope factory recommends customers to use better quality blade thorn rope, which eliminates the cumbersome time and cost of subsequent demolition and installation.

...

perforated fiberglass sheets 【perforated fiberglass sheets】

Read MoreGalvanized iron wire is divided into hot-dip galvanized wire and cold galvanized wire, using low carbon steel wire processing, after drawing forming, pickling rust removal, high temperature annealing, hot-dip galvanized, cooling and other processes. With good toughness and elasticity, the amount of zinc can reach 300 grams/square meter. It has the characteristics of thick galvanized layer and strong corrosion resistance. Galvanized iron wire can cut off the tie wire used in the building, the length is 20cm 30cm 40cm, can be cut off according to the requirements.

perforated fiberglass sheets...

perforated fiberglass sheets 【perforated fiberglass sheets】

Read Moreperforated fiberglass sheets

...

perforated fiberglass sheets 【perforated fiberglass sheets】

Read More

perforated fiberglass sheetsAs we all know, even if it is the same kind of steel wire, because of the steel making process, wire drawing process and equipment are not the same, so the quality of steel wire production is not the same. Due to the different mechanical properties of steel wire itself, flattening process and equipment, the width and elongation of steel wire in the flattening process have different effects. Therefore, in the selection of wire diameter, the following three factors should be considered:

...

perforated fiberglass sheets 【perforated fiberglass sheets】

Read MoreGalvanized wire to galvanized evenly, a body is now its cross section, the second is the longitudinal uniformity. In the actual operation process, such as the jitter of steel wire, the surface scum in the plating pot and other reasons will cause the accumulation of galvanized layer on the surface of galvanized wire, and efforts should be made to solve the problem.

perforated fiberglass sheets...

perforated fiberglass sheets 【perforated fiberglass sheets】

Read Moreperforated fiberglass sheets

...

perforated fiberglass sheets 【perforated fiberglass sheets】

Read More

Popular articles

- Two, cold galvanized wire production process of galvanized. Galvanizing is the core process in the production of cold galvanized wire, mainly by soaking the steel wire in a molten zinc solution to form a zinc layer on its surface.

- Three, the use of different technologies

Galvanized wire mesh is divided into hot dip galvanized wire mesh and cold galvanized wire mesh. Galvanized steel wire net selects the high quality low carbon steel wire, iron wire factory made by precision of automation machinery welding technology processing, smooth surface, firm structure, integrity is strong, even if the local cutting of galvanized steel wire net, or local also under pressure from loose phenomenon, after molding, wire mesh galvanized corrosion resistance good, has the advantage that the general steel mesh does not have.

Post time: 09-09-22

Latest articles

-

-

After the wire mesh appears black spots, you can choose the appearance of treatment to deal with this problem, such as galvanized, paint, dip plastic to deal with, after the appearance of the welding mesh surface smooth and bright, beautiful and generous.

-

In white iron, its carbon and iron phase into iron carbide, crack white, extremely strong and brittle, for the malleable steel material. Alloy grades are made up of various alloying elements with different compositions and structures. Because the alloy element in the iron can make the copper material thick strengthening degree, hardness, impact force, strength resistance, collection rate, elongation rate, so the alloy iron in the exercise of high quality iron, is an additive element.

-

Zinc dipping time should be adjusted according to the thickness of wire diameter. The method of adjustment is the length of the distance between the lead screw on the zinc pot and the ceramic sinking roller. Thick wire diameter zinc dipping time should be long, fine wire diameter zinc dipping time should be short, zinc dipping length in the range of 2~3.5m, which is also to reduce the zinc consumption of steel wire galvanized, is an aspect of maintaining the uniformity of zinc layer.

-

Steel wire mesh by its own unique advantages in construction occupation, reinforcement anti-crack occupation is indispensable reinforcement anti-crack data, high product error is small, mesh mesh uniform, welding firm, strong acceptance, not easy to deformation, steel wire mesh in different fields have different called, in bridge engineering construction people call it soft reinforcement.

-

Links

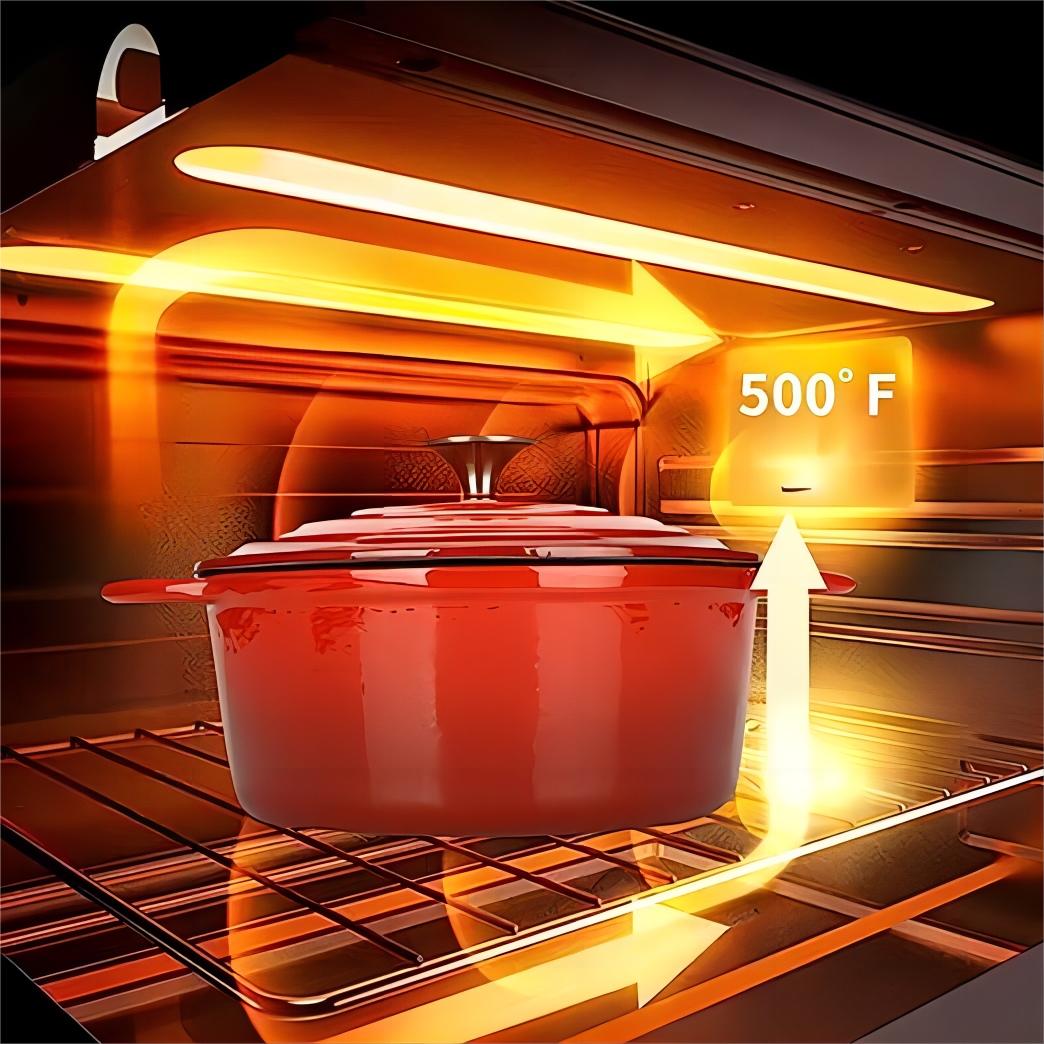

- Enameled cast iron pots with lids have become a staple in many kitchens around the world. These versatile and durable cooking vessels offer a range of benefits that make them a popular choice for home cooks and professional chefs alike.

- The history of cast iron cookware dates back to ancient China, where it was first used in the 5th century BC. However, it wasn't until the 18th century in Europe that the process of casting iron into cookware shapes was perfected, leading to the birth of the cast iron coated pot. Today, these pots, often adorned with a non-stick enamel coating, have evolved into a kitchen staple, cherished for their durability and versatility.

However, there’s no need to worry because we’re here to help you. French skillets have recently gained popularity in American kitchens, but many people are unfamiliar with them. After all, a pan is a pan, right?

Moreover, the large cooking area is ideal for preparing family-sized meals or multiple dishes simultaneously Moreover, the large cooking area is ideal for preparing family-sized meals or multiple dishes simultaneously

Moreover, the large cooking area is ideal for preparing family-sized meals or multiple dishes simultaneously Moreover, the large cooking area is ideal for preparing family-sized meals or multiple dishes simultaneously Moreover, they require less seasoning than bare cast iron, making them user-friendly for those new to the world of cast iron cooking Moreover, they require less seasoning than bare cast iron, making them user-friendly for those new to the world of cast iron cooking

Moreover, they require less seasoning than bare cast iron, making them user-friendly for those new to the world of cast iron cooking Moreover, they require less seasoning than bare cast iron, making them user-friendly for those new to the world of cast iron cooking

The enamel coating creates a smooth, glossy finish that prevents food from sticking to the pan The enamel coating creates a smooth, glossy finish that prevents food from sticking to the pan

The enamel coating creates a smooth, glossy finish that prevents food from sticking to the pan The enamel coating creates a smooth, glossy finish that prevents food from sticking to the pan A solid collection might include a spatula, ladle, tongs, wooden spoons, and a whisk A solid collection might include a spatula, ladle, tongs, wooden spoons, and a whisk

A solid collection might include a spatula, ladle, tongs, wooden spoons, and a whisk A solid collection might include a spatula, ladle, tongs, wooden spoons, and a whisk

Over time, this patina develops into a smooth, dark coating that is easy to clean and care for Over time, this patina develops into a smooth, dark coating that is easy to clean and care for

Over time, this patina develops into a smooth, dark coating that is easy to clean and care for Over time, this patina develops into a smooth, dark coating that is easy to clean and care for