6. Variety of Stitch Options While a straight stitch is essential, having multiple stitch options, such as zigzag and decorative stitches, can enhance your projects and give them a professional touch.

good sewing machine for upholstery

2. Use a Thick Needle and Strong Thread As mentioned earlier, using heavy-duty needles and thread ensures that your stitches hold under stress and enhances the durability of your project.

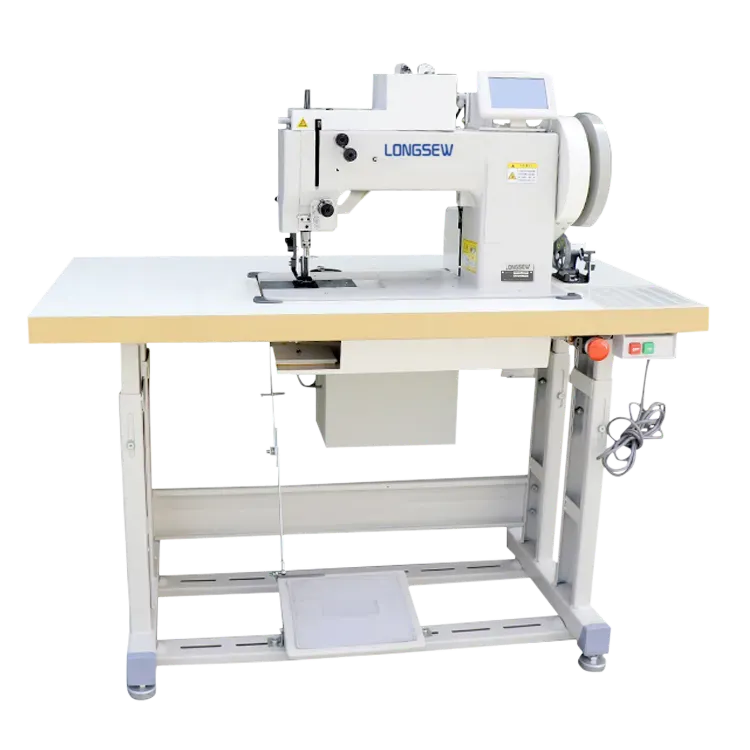

A heavy-duty sewing machine designed for compound feed is a powerful tool that can handle the toughest sewing tasks with ease. These machines are specifically built to sew through multiple layers of fabric, heavy materials, and even tougher materials like leather and canvas. Whether you're a professional seamstress or a hobbyist, a compound feed heavy-duty sewing machine can make your projects more efficient and produce high-quality results.

Before buying a heavy-duty sewing machine, ensure that your space can accommodate the larger size. Most heavy-duty machines are set on tables that measure 30 to 40 inches. In addition, the tables may be height adjustable, so if you are tall, you will want to ensure that the tables can raise to a comfortable height for you. And finally, decide how many heavy-duty sewing machines you will need. If you are planning on operating a small sewing business, you may want to ensure you have enough space for 2 machines, tables, or more!

Basic Techniques

The technological advancements in hi-speed lockstitch machines also include features such as programmable sewing patterns, automatic thread cutting, and built-in sensors that detect thread breakage. These innovations not only expedite the sewing process but also minimize the risk of errors and material wastage. This level of precision is particularly beneficial in high-stake environments, such as fashion design, where the margin for error may be minimal.

When tackling thick materials, it’s important to use the right needles and thread. A sewing machine that can accommodate large, robust needles (like a 16 or 18 size) is ideal for heavy fabrics. Similarly, using heavy-duty thread will help prevent breakage and ensure strong seams. Make sure your sewing machine is compatible with such needles and threads.

Another important feature to consider is the machine’s stitching capabilities. Look for a heavy duty sewing machine that offers a variety of stitch options, including straight stitch, zigzag stitch, and decorative stitches. This will give you the flexibility to tackle a wide range of sewing projects with ease.

The performance of a sewing machine, regardless of its build or intended use, greatly depends on its maintenance. When sewing light fabrics, even minor hiccups caused by a lack of maintenance can lead to significant issues, from uneven stitches to fabric damage.

In conclusion, using a double needle can significantly enhance your sewing projects, providing aesthetic and functional advantages. With practice and experimentation, you’ll quickly master the double needle technique and expand your sewing repertoire. Happy sewing!

The Use of Double Needle Sewing Machines

Double Needle Walking Foot Sewing Machine for Sale

The New Home Super Automatic Sewing Machine is designed to cater to a wide range of sewing needs, whether you are mending clothes, creating intricate quilts, or even embarking on fashion design projects. One of its most significant features is its automation capabilities. With built-in stitch patterns and automatic buttonhole functions, users can achieve professional-looking results without needing extensive sewing knowledge. The machine can automatically adjust for stitch length and width, ensuring precision and consistency in every project.

Versatility at Its Best

Understanding Heavy Canvas

The Significance of a Threader for Needlework A Seamstress's Best Friend

Speed

Weight. A heavy duty machine typically weighs more than 15 pounds, with many being closer to 20 or more. This is important because you will be working with thicker, heavier fabrics and a lightweight machine can easily topple over or it will simply move along the table as you try to feed fabric through it.

2. Use a Walking Foot A walking foot can help feed the fabric and prevent slippage, ensuring that your seams are even and aligned properly.

Some machines also incorporate additional functionalities such as printing, labeling, and even inspection mechanisms to ensure quality control. For example, certain models allow operators to print expiration dates or barcodes directly onto the bags during the sealing process, eliminating the need for separate labeling operations and enhancing operational efficiency.