welded wire fabric reinforcement

Latest articles

welded wire fabric reinforcement

...

welded wire fabric reinforcement 【welded wire fabric reinforcement】

Read Morewelded wire fabric reinforcement

...

welded wire fabric reinforcement 【welded wire fabric reinforcement】

Read More

welded wire fabric reinforcementTwo, the production process is different

...

welded wire fabric reinforcement 【welded wire fabric reinforcement】

Read More

welded wire fabric reinforcement

Post time: 28-12-22...

welded wire fabric reinforcement 【welded wire fabric reinforcement】

Read MoreMaterial: low carbon steel wire

welded wire fabric reinforcement...

welded wire fabric reinforcement 【welded wire fabric reinforcement】

Read Morewelded wire fabric reinforcement

...

welded wire fabric reinforcement 【welded wire fabric reinforcement】

Read More

welded wire fabric reinforcementGalvanized wire in acid, alkali, sodium chloride aqueous solution of poor corrosion resistance, in the atmosphere containing carbon dioxide and hydrogen sulfide, as well as Marine atmosphere is not corrosion resistance. In high temperature and high humidity air and containing organic acid atmosphere is small, galvanized layer is also easy to be corroded. Galvanized wire and general wire is very different, general wire is cheap, and because the iron is not very stable, easy to rust in the wet place, so the stability is not very good, the life is not very long.

...

welded wire fabric reinforcement 【welded wire fabric reinforcement】

Read Morewelded wire fabric reinforcement

...

welded wire fabric reinforcement 【welded wire fabric reinforcement】

Read More

welded wire fabric reinforcement

Post time: 18-11-22...

welded wire fabric reinforcement 【welded wire fabric reinforcement】

Read MorePurpose of galvanized hexagonal net: building wall fixed, heat preservation, heat insulation

welded wire fabric reinforcement...

welded wire fabric reinforcement 【welded wire fabric reinforcement】

Read More

Popular articles

① The diameter of galvanized iron wire for drawing shall not be less than 4mm, and the diameter of galvanized iron wire for binding shall not be less than 2.6mm.

The best way to manage off-road safety is to carry out management and protection from the source, maximize the safety of people’s lives and property, and reduce the non-operational costs of railway enterprises, which is a key content of railway safety work in the new era. At this time, it is necessary to install protective nets on both sides of the railway, which is what we usually say, blade barbed rope protective nets, which can prevent accidents.

Second: positive and negative twisting rope cost-effective

Latest articles

-

Galvanized iron wire can be divided into hot-dip galvanized iron wire and cold galvanized iron wire according to different processing methods. Galvanized iron wire is more prominent in its corrosion resistance. Galvanized iron wire has good toughness and elasticity, the amount of zinc can reach 300 g/square meter, with thick galvanized layer, strong corrosion resistance and other characteristics. Galvanized iron wire products are widely used in construction, handicrafts, wire mesh preparation, the production of galvanized hook mesh, wall mesh, highway guardrail, product packaging and daily civilian and other fields.

-

Post time: 18-10-22 -

Raw material of wire mesh sheet cold drawn low carbon steel wire base material can choose low carbon steel hot rolled disk bar or hot rolled smooth steel bar. The base material number and diameter of cold-drawn low carbon steel wire can be confirmed according to the rules in the table below. During the cold drawing process, the surface shrinkage rate of each drawing should not be greater than the wire mesh before cold drawing. Annealing shall not be carried out during wire drawing. If butt welding is required, the same production unit and base material of the same number should be selected. The appearance quality of wire mesh should not affect wire drawing. When the welding function is poor or brittle fracture occurs, special inspection should be carried out according to relevant standards.

-

-

Combined restrictions of fence network and maintenance network: Plot fence network, garden villa, private swimming pool, courtyard on the lawn, city scene, municipal transportation, sports venues, airport port, office school, military equipment, prison farm, industrial park, tourist resort, distribution center, The specifications and parameters of the fence network are as follows: 800, 1000, 1200, 1400, 1600, 1800, 2000, 2200, 2400 (mm) : 2000, 2500, 3000 mesh spacing (mm).

-

Hexagonal cage has a wide range of applications, with the progress of science and technology, has been extended to the major hydraulic, civil engineering. Geotechnical engineering and other projects. In the hydraulic hexagonal cage in the river construction to close the utility, it is considered appropriate to use hexagonal cage to fill stone, fixed river, can be used to avoid river erosion brought water and soil loss. In civil engineering projects, hexagonal cage is considered appropriate and the use of similar particle size volume filling, the connection between the cage is formed into a wall, which is the stone cage mesh retaining wall.

Links

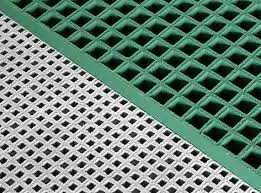

Molded Fiberglass Grating:

Gratings & Covers

frp stair tread. The production process of FRP results in less waste compared to traditional materials. Additionally, the long lifespan of FRP reduces the need for replacements, further minimizing environmental impact. In a world becoming increasingly conscious of eco-friendly practices, FRP stair treads stand out as a green choice for both residential and commercial buildings.

frp stair tread. The production process of FRP results in less waste compared to traditional materials. Additionally, the long lifespan of FRP reduces the need for replacements, further minimizing environmental impact. In a world becoming increasingly conscious of eco-friendly practices, FRP stair treads stand out as a green choice for both residential and commercial buildings.

The Strength & Durability of FRP Grating

The Strength & Durability of FRP Grating

In the chemical industry, FRP is used for containment vessels, piping systems, and equipment, ensuring safe and efficient operation without the risk of material degradation In the chemical industry, FRP is used for containment vessels, piping systems, and equipment, ensuring safe and efficient operation without the risk of material degradation

In the chemical industry, FRP is used for containment vessels, piping systems, and equipment, ensuring safe and efficient operation without the risk of material degradation In the chemical industry, FRP is used for containment vessels, piping systems, and equipment, ensuring safe and efficient operation without the risk of material degradation corrosion resistant frp.

corrosion resistant frp.