5 foot welded wire fence panels

Latest articles

5 foot welded wire fence panels2, mesh, mesh also directly affect the price of stone cage net

...

5 foot welded wire fence panels 【5 foot welded wire fence panels】

Read MoreGalvanized hexagonal mesh uses: building wall fixed, heat preservation, heat insulation; Power plant piping, boiler heating; Anti-freezing, residential protection, landscaping protection; Raise chicken and duck, isolate chicken and duck house, play the role of protecting poultry; Protect and support seawalls, hillsides, roads and Bridges and other waterworks.

5 foot welded wire fence panels...

5 foot welded wire fence panels 【5 foot welded wire fence panels】

Read More1, prepare disinfection dog cage utensils: small brushes, old toothbrushes, latex gloves (can effectively prevent corrosive pure disinfectant damage to the skin), birdish, and household commonly used disinfectant.

5 foot welded wire fence panels...

5 foot welded wire fence panels 【5 foot welded wire fence panels】

Read More5 foot welded wire fence panels

...

5 foot welded wire fence panels 【5 foot welded wire fence panels】

Read MoreThe new weaving machine can weave 3.5m wide, 5cm narrow, can be customized according to customer requirements.

5 foot welded wire fence panels...

5 foot welded wire fence panels 【5 foot welded wire fence panels】

Read More

5 foot welded wire fence panelsThe large roll of galvanized silk should be coated with oil, the fiber core is dipped in oil, and the grease should be able to protect the fiber core from decay and corrosion, the iron wire moistens the fiber, and lubricates the wire rope from the inside. The surface is coated with oil so that all the wire surface in the rope strand is evenly coated with a layer of anti-rust lubricating grease, which is used for the mine rope with friction lifting and mineral water, to be coated with black grease with increased wear and strong water resistance. Other uses are coated with red oil oil with strong film and good rust resistance, and require it to have a thin oil layer, which is easy to keep clean during the operation.

...

5 foot welded wire fence panels 【5 foot welded wire fence panels】

Read More

5 foot welded wire fence panelsThe wire mesh is composed of low carbon steel wire or medium carbon steel wire, high carbon steel wire or stainless steel wire. There are two kinds of manufacturing technology of steel wire mesh, one is the weaving method, the other is the welding connection, the formation of grid.

...

5 foot welded wire fence panels 【5 foot welded wire fence panels】

Read More

5 foot welded wire fence panels

Post time: 29-08-22...

5 foot welded wire fence panels 【5 foot welded wire fence panels】

Read More

5 foot welded wire fence panelsWet air in rain and snow climate, steel mesh sheet exposed, easy to rust, to avoid affecting the use of steel mesh, it is necessary to carry out simple rust prevention treatment, of course, slight rust float will not affect the use of steel mesh. Common network site storage, rainy days, heavy snow, rainy days and rainy days, how to better save the steel mesh, this is a lot of friends need to consider.

...

5 foot welded wire fence panels 【5 foot welded wire fence panels】

Read More5 foot welded wire fence panels

...

5 foot welded wire fence panels 【5 foot welded wire fence panels】

Read More

Popular articles

Because of the high carbon content, simple cracks occur during water quenching, so double liquid quenching (water quenching + oil cooling) is mostly used, and oil quenching is mostly used for small cross section parts. This type of steel is generally used after quenching by medium temperature tempering or normalizing or in the surface quenching state. Mainly used for manufacturing spring and wear-resistant parts.

3. The transport, storage and use of the binder of galvanized wire mesh should adopt safety and fire prevention methods according to the relevant regulations, so as to be safer.

In sulfur dioxide, hydrogen sulfide and Marine atmosphere, zinc corrosion resistance is poor, especially in the high temperature and high humidity atmosphere containing organic acid, galvanized wire galvanized layer is easy to be corroded. The uniformity of the galvanized layer on the surface of galvanized wire and the color of galvanized wire, the galvanized layer on the surface of high-quality galvanized wire is uniform, zinc adhesion is good, and the color is white, there is no leakage plating and rust points and other problems.

Latest articles

-

-

-

-

3. The structure of the dog cage should be reasonable

-

-

If the surface of galvanized wire is black and the galvanized layer is thin and uneven, the galvanized wire is partly because the inventory storage time is longer, but also because the production technical requirements of galvanized wire do not meet the standard and lead to the quality problems of galvanized wire. According to the use of galvanized wire is different, galvanized wire has soft and hard, then the galvanized wire used for binding requires the flexibility of galvanized wire is better, the flexibility of galvanized wire is good, and it can be easy for workers to operate.

Links

- FRP, or Fiber Reinforced Polymer, has emerged as a revolutionary material in the construction and engineering industry, particularly in the manufacturing of spraying pipes. This cutting-edge technology offers a myriad of benefits that conventional materials often fail to provide. This 600-word article delves into the intricacies of FRP spraying pipes, their advantages, applications, and their pivotal role in shaping the future of infrastructure.

As a result, drillers can achieve greater depths with fewer rod replacements, leading to increased operational efficiency As a result, drillers can achieve greater depths with fewer rod replacements, leading to increased operational efficiency

As a result, drillers can achieve greater depths with fewer rod replacements, leading to increased operational efficiency As a result, drillers can achieve greater depths with fewer rod replacements, leading to increased operational efficiency speed drill rod.

speed drill rod. rock drill shank adapter. For instance, spline shank adapters are commonly used in heavy-duty drilling due to their robust design and increased torque transmission. Meanwhile, hexagonal shank adapters, with their six-sided profile, offer better stability and resistance to torsion. Additionally, there are adapters designed for use with DTH (Down-the-Hole) hammers, which are specifically engineered for deep hole drilling.

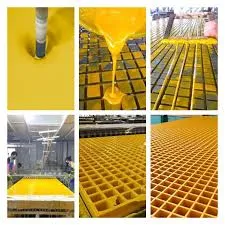

rock drill shank adapter. For instance, spline shank adapters are commonly used in heavy-duty drilling due to their robust design and increased torque transmission. Meanwhile, hexagonal shank adapters, with their six-sided profile, offer better stability and resistance to torsion. Additionally, there are adapters designed for use with DTH (Down-the-Hole) hammers, which are specifically engineered for deep hole drilling.Fiberglass Covered Grating:

Fiberglass grating attachments and clips are specially designed to secure fiberglass grating or plates to the supporting structures. Additionally, they are used to fasten together adjacent grating panels, which minimizes load-induced differential deflection. All fiberglass attachments and clips are made of Type 316 stainless steel, and are available in 1, 1-1/2 and 2 sizes. For more on fiberglass attachments and clips, click here.

The inherent strength and impact resistance of GRP provide superior crash protection for passengers The inherent strength and impact resistance of GRP provide superior crash protection for passengers

The inherent strength and impact resistance of GRP provide superior crash protection for passengers The inherent strength and impact resistance of GRP provide superior crash protection for passengers grp car. Its monocoque construction, reinforced by the GRP material, creates a robust safety cell that absorbs and disperses energy during collisions, ensuring occupant safety.

grp car. Its monocoque construction, reinforced by the GRP material, creates a robust safety cell that absorbs and disperses energy during collisions, ensuring occupant safety. The tool's compact size and light weight make it easy to maneuver in tight spaces, while its durable construction ensures long-lasting performance in even the most demanding conditions The tool's compact size and light weight make it easy to maneuver in tight spaces, while its durable construction ensures long-lasting performance in even the most demanding conditions

The tool's compact size and light weight make it easy to maneuver in tight spaces, while its durable construction ensures long-lasting performance in even the most demanding conditions The tool's compact size and light weight make it easy to maneuver in tight spaces, while its durable construction ensures long-lasting performance in even the most demanding conditions rotary jack hammer.

rotary jack hammer. By improving efficiency, companies can reduce operating costs, increase profitability, and enhance their competitive position in the market By improving efficiency, companies can reduce operating costs, increase profitability, and enhance their competitive position in the market

By improving efficiency, companies can reduce operating costs, increase profitability, and enhance their competitive position in the market By improving efficiency, companies can reduce operating costs, increase profitability, and enhance their competitive position in the market speed drill rod.

speed drill rod.FRP Molded Grating is a material that combines fiberglass with resin, pigments, and other additives into a mold, resulting in grating products with the size of the mold panel used. This FRP Molded Grating is lightweight, corrosion-resistant, and able to withstand harsh environmental conditions. With precisely formed grating, FRP Molded Grating offers high structural strength and anti-slip properties, making it an ideal choice for various industrial and commercial applications.

jumbo drill bits. Some feature cutting edges that rotate at high speeds, while others utilize a hammering action for penetration. Many are equipped with replaceable cutting inserts, allowing for cost-effective maintenance and repair.

jumbo drill bits. Some feature cutting edges that rotate at high speeds, while others utilize a hammering action for penetration. Many are equipped with replaceable cutting inserts, allowing for cost-effective maintenance and repair. They do not support combustion and produce minimal smoke, ensuring safety in case of a fire emergency They do not support combustion and produce minimal smoke, ensuring safety in case of a fire emergency

They do not support combustion and produce minimal smoke, ensuring safety in case of a fire emergency They do not support combustion and produce minimal smoke, ensuring safety in case of a fire emergency frp duct. This feature, along with their acoustic insulation capabilities, makes them a preferred choice for commercial and industrial applications.

frp duct. This feature, along with their acoustic insulation capabilities, makes them a preferred choice for commercial and industrial applications.