100 ft chain link fence

Latest articles

100 ft chain link fence

...

100 ft chain link fence 【100 ft chain link fence】

Read More100 ft chain link fence

...

100 ft chain link fence 【100 ft chain link fence】

Read More100 ft chain link fence

...

100 ft chain link fence 【100 ft chain link fence】

Read More

100 ft chain link fenceNow the production of stainless steel blade barbed rope unless it is a specially customized model, under normal circumstances are the use of a knife length of 22mm mold production, that is, we usually say bto-22 type. It’s not necessarily the case that there are specifications from 11mm to 65mm. Unless the customer insists on customizing the required length, the barbed rope manufacturer produces bto-22 stainless steel blade barbed rope.

...

100 ft chain link fence 【100 ft chain link fence】

Read More100 ft chain link fence

...

100 ft chain link fence 【100 ft chain link fence】

Read More100 ft chain link fence

...

100 ft chain link fence 【100 ft chain link fence】

Read More

100 ft chain link fenceHot dip galvanizing is dipped in zinc liquid melted by heating, with fast production speed and thick but uneven coating. The market allows a low thickness of 45 microns and a high of more than 300 microns. The color is dark, the consumption of zinc metal is much, the formation of infiltration layer with the matrix metal, the corrosion resistance is good, and the outdoor environment of hot dip galvanized can be maintained for decades. Application range of hot dip galvanizing: because the coating is thicker, hot dip galvanizing has better protective performance than electric galvanizing, so it is an important protective coating for iron and steel parts in harsh working environment. Hot-dip galvanized products are widely used in chemical equipment, petroleum processing, Marine exploration, metal structure, power transmission, shipbuilding and other industries, in the field of agriculture such as sprinkler irrigation, greenhouse and construction industry such as water and gas transmission, wire casing, scaffolding, Bridges, highway guardrail and other aspects, has been widely used.

...

100 ft chain link fence 【100 ft chain link fence】

Read MoreThe acid activation solution in the production process can remove the corrosion products and oxide film on the surface of the low carbon steel wire without excessive corrosion to the matrix. Galvanized wire can be zincate galvanized or chloride galvanized process, should use appropriate additives to obtain the low carbon steel wire standard requirements of the coating. When galvanized wire after light plating should be light treatment. Control the temperature of the bath of galvanized wire.

100 ft chain link fence...

100 ft chain link fence 【100 ft chain link fence】

Read More(4) Stop the use of more than two strands of galvanized iron wire around the operation method.

100 ft chain link fence...

100 ft chain link fence 【100 ft chain link fence】

Read MoreSteel wire mesh is finished by fine welding of active welding equipment. The material can be divided into cold wire drawing, hot dip galvanizing, cold galvanizing, dip plastic, etc. To be used for bridge reinforcement, bridge deck pavement, building reinforcement, etc.

100 ft chain link fence...

100 ft chain link fence 【100 ft chain link fence】

Read More

Popular articles

The barbed wire factory will store the blade barbed wire inventory in the appropriate place, because it understands the product characteristics.

Hexagonal mesh is made of galvanized iron wire woven by automatic mesh machine, mesh into regular hexagonal shape, mesh standard, beautiful, mesh size can be customized according to customer requirements, usually 27mm,20mm, 13mm, wire diameter from 0.40mm to 1.20mm, to meet the requirements of different customers.

- Galvanized hexagonal net is a kind of galvanized metal wire mesh, mesh shape is hexagonal.

Latest articles

-

Post time: 19-09-22 -

-

-

Post time: 22-11-22 -

Large hexagonal net called stone cage net, mainly used for mountain preparedness protection, hydraulic construction, etc. Small wire hexagonal net is used as a good material for culture, will twist the hexagonal net in the welding of the iron frame on the hexagonal net welding into chicken cage, pigeon cage, rabbit cage and other cage, hexagonal net is an excellent material for culture with net.

-

These citizens, who love the subway, rely on it and enjoy its speed, often like to call themselves the U-pin price. Is widely used in industry, agriculture, farming, construction, transportation and other welded wire mesh is used in the field of high quality low carbon wire line of welding and become, then after cold, hot dip plating, PVC plastic coated surface passivation, such as plasticizing processing, production of metal mesh with smooth surface, uniform mesh, solder joint is firm, stability, corrosion resistance, good corrosion resistance characteristics. The U nail price is made of high quality stainless steel wire row welding; For example, machine protective cover, animal animal fence, flower fence, window guard bar, channel fence, poultry cage and home office food basket, paper basket and decorative articles, more acid, alkali, welding firm, beautiful and other characteristics.

Links

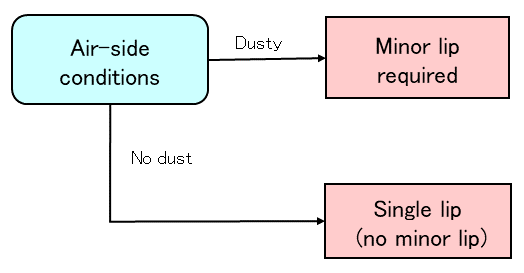

• Quick response (centrifugal hydraulic pressure canceling mechanism) throughout the rotation range

How Oil Seals

Copper and nickel are relatively inexpensive, while platinum is much more expensive but also much more durable and resistant to wear Copper and nickel are relatively inexpensive, while platinum is much more expensive but also much more durable and resistant to wear

Copper and nickel are relatively inexpensive, while platinum is much more expensive but also much more durable and resistant to wear Copper and nickel are relatively inexpensive, while platinum is much more expensive but also much more durable and resistant to wear car spark plug price.

car spark plug price.

Refit the rocker or cam cover, aligning its fixing holes with those on the head. Check that the gasket edge aligns with the cover flange all round, and is not distorted. If necessary, adjust it gently with tweezers or long-nosed pliers. Tighten bolts evenly to just compress the gasket.

Maintenance and Replacement of Spark Plugs

One of the primary advantages of natural rubber gaskets is their excellent sealing properties. Due to their inherent elasticity and compression set resistance, natural rubber gaskets can effectively conform to irregular surfaces, creating a tight seal that prevents fluids or gases from leaking. This is especially important in industries such as automotive and aerospace, where even the smallest leak can lead to catastrophic consequences.

Materials for Oil Seals

See here for more information and useful fitting tips.

Figure 5 explains the JTEKT seal numbering system.

Seal numbers consist of

(1) the seal type code,

(2) the spring code,

(3) the lip type code,

(4) the dimensional numbers, and

(5) the special type code,

and Table 6 shows examples of each of these codes/numbers.