metal panel perforated

Latest articles

metal panel perforated

...

metal panel perforated 【metal panel perforated】

Read MoreAfter the wire mesh appears black spots, you can choose the appearance of treatment to deal with this problem, such as galvanized, paint, dip plastic to deal with, after the appearance of the welding mesh surface smooth and bright, beautiful and generous.

metal panel perforated...

metal panel perforated 【metal panel perforated】

Read More

metal panel perforatedU nail price is made of high quality stainless steel wire row welding; For example, machine protective cover, animal animal fence, flower fence, window guard bar, channel fence, poultry cage and home office food basket, paper basket and decorative articles, more acid, alkali, welding firm, beautiful and other characteristics.

...

metal panel perforated 【metal panel perforated】

Read MoreGalvanized also has several different methods, the so-called hot dip galvanizing is put racing in the zinc bath, need to clean them on metal, which ensures that formed between metal and coating adhesive, after cleaning, the matrix metal is dissolved, to clear any residual oxides of residue and then immerse the substrate metal heating liquid zinc, and metallurgical bonding is formed.

metal panel perforated...

metal panel perforated 【metal panel perforated】

Read Moremetal panel perforated

...

metal panel perforated 【metal panel perforated】

Read More

metal panel perforated

Post time: 29-06-22...

metal panel perforated 【metal panel perforated】

Read Moremetal panel perforated

...

metal panel perforated 【metal panel perforated】

Read More

metal panel perforatedThe hook mesh is a good material for flood control and flooding. Can also be used for arts and crafts manufacturing, mechanical equipment transport network mountain beautification network – high strength steel wire grid (hook mesh, diamond mesh) hook mesh mountain protection application principle, hook mesh interests, mesh uniform, flat, woven concise, hook woven, beautiful and generous, net, net width, wire diameter is thicker, not easy to corrosion, long life, strong usefulness.

...

metal panel perforated 【metal panel perforated】

Read MoreThe first difference is in the amount of zinc.

metal panel perforated...

metal panel perforated 【metal panel perforated】

Read MoreGalvanized hexagonal mesh uses: building wall fixed, heat preservation, heat insulation; Power plant piping, boiler heating; Anti-freezing, residential protection, landscaping protection; Raise chicken and duck, isolate chicken and duck house, play the role of protecting poultry; Protect and support seawalls, hillsides, roads and Bridges and other waterworks.

metal panel perforated...

metal panel perforated 【metal panel perforated】

Read More

Popular articles

- Galvanized iron wire is divided into hot galvanized wire and cold galvanized wire, using low carbon steel wire processing, after drawing molding, pickling rust removal, high temperature annealing, hot galvanized, cooling and other processes. It has good toughness and elasticity, and the amount of zinc can reach 300 grams/square meter. It has the characteristics of thick galvanized layer and strong corrosion resistance. Galvanized iron wire can be cut off in the construction of the tie wire, the length of 20cm, 30cm and 40cm, can be cut off according to requirements.

- Wire rod to stop normalizing or soxaustenitizing treatment, large specifications with spheroidizing annealing instead. In the middle, especially before the waste product drawing process of thermal disposal throughout the selection of soxaustenitizing disposal. Decarbonization should be prevented during thermal disposal. Sulfuric acid or hydrochloric acid pickling was used to remove the oxide sheet after hot treatment. Coating (see lubrication carrier) can be dipped in lime, phosphating, borax disposal or copper plating.

Latest articles

-

To many people, a dog cage looks like a prison, but for dogs who have been raised on cage training, it is their home and shelter. A cage should be a comfortable place. Never put a dog in a cage for no reason. They will see it as punishment. (Why do many dogs fail to adapt to their owners’ commands, because whether the paparazzi can come out or not, it is also seen as a punishment.

-

-

-

-

6. It’s easy for your dog to get used to a strange place as long as it has a home he’s familiar with, so you can take your dog on a trip instead of leaving him at home.

-

③ The galvanized iron wire shall not be damaged when it is tightened.

Links

- If you're considering adding decorative cast iron panels to your home, there are many options available. You can choose from a wide range of designs and patterns, including floral motifs, geometric shapes, and classic. You can also find panels in different sizes and thicknesses, so you can find the perfect fit for your space.

5. Sustainable and environmentally friendly

- Steel Door Lock Box A Comprehensive Security Solution

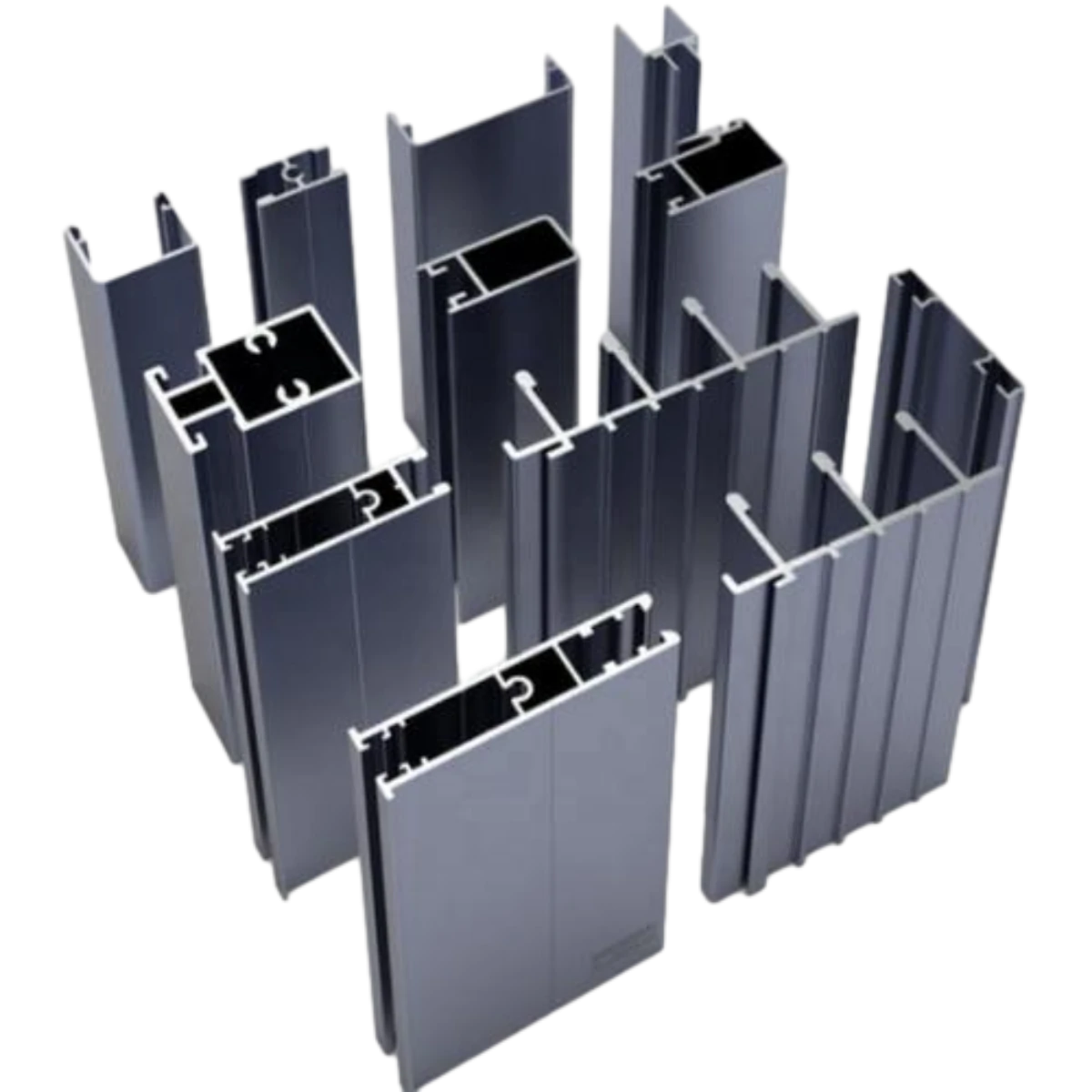

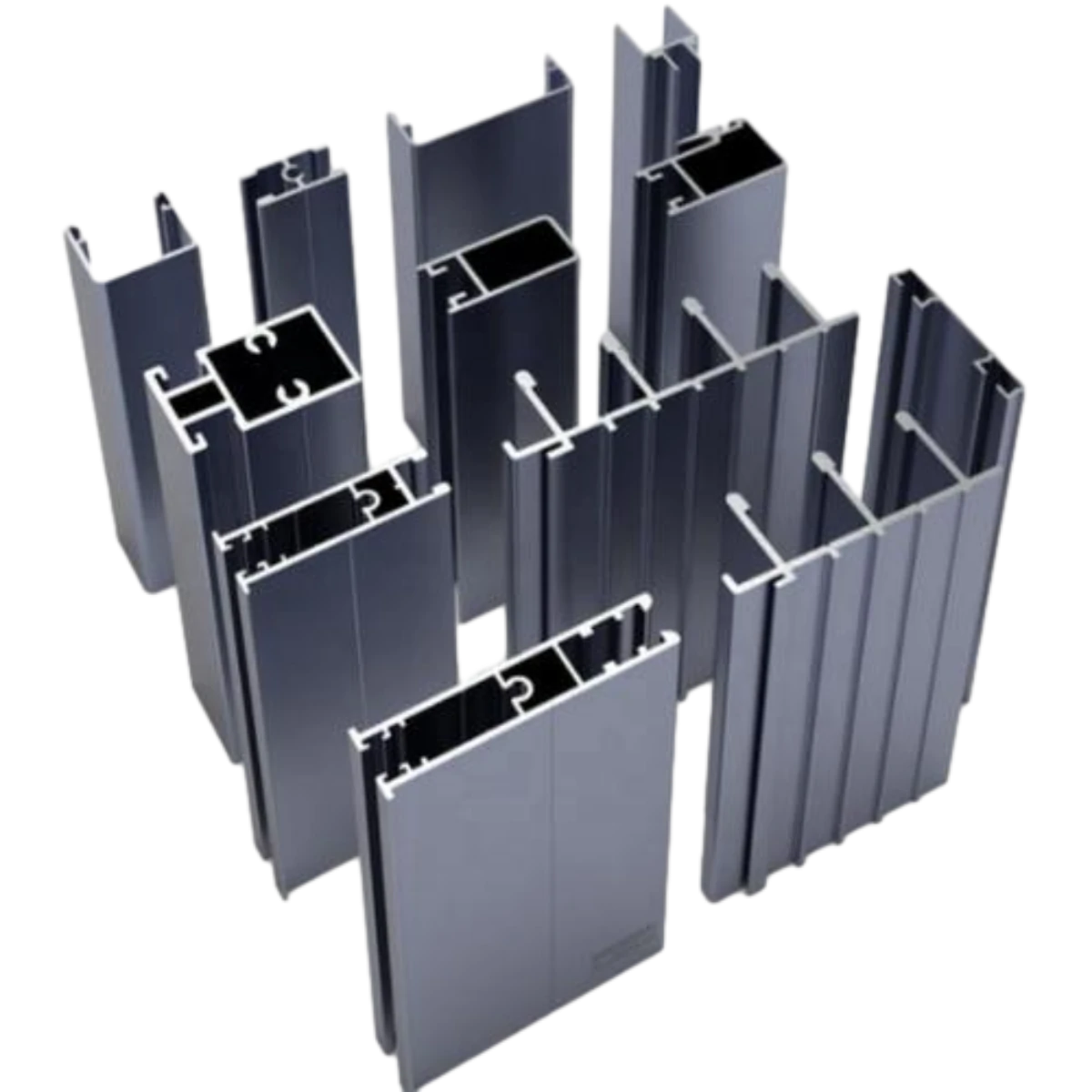

Mill-Finished, Anodizing, Powder Coating, PVDF, Electrophoresis, Wood Grain, Polishing, Brushing, etc

Moreover, the desire to innovate and evolve has led to the development of treatments and materials that enhance the rust resistance of wrought iron. For instance, the introduction of rust-resistant alloys and protective coatings reflects human ingenuity and the determination to combat deterioration. This evolution is not merely a technological advancement; it signifies a collective will to preserve history and craftsmanship inherent in wrought ironwork.

will wrought iron rust

WHAT ARE THE TYPES OF ALUMINIUM WINDOWS?

Enhanced Security

Aluminium Profiles Quality Test │ Wall Thickness

This process applies chemicals and electricity on the surface of extruded aluminum profile to form a relatively thick layer of oxide.

In conclusion, sliding door runner wheels are essential for ensuring that doors slide smoothly and reliably. By understanding the different types available, maintaining them properly, and selecting the right wheels for your specific needs, you can extend the life of your sliding doors and enhance their functionality. Whether you are installing new doors or replacing worn wheels, a little attention to these components can go a long way in safeguarding the performance of your sliding doors for years to come.

Unlike handles made from other materials that may require special cleaning products or techniques, stainless steel handles can be easily wiped clean with a soft cloth and mild soap Unlike handles made from other materials that may require special cleaning products or techniques, stainless steel handles can be easily wiped clean with a soft cloth and mild soap

Unlike handles made from other materials that may require special cleaning products or techniques, stainless steel handles can be easily wiped clean with a soft cloth and mild soap Unlike handles made from other materials that may require special cleaning products or techniques, stainless steel handles can be easily wiped clean with a soft cloth and mild soap brushed stainless steel cupboard door handles. This makes them a practical choice for busy homeowners who want to keep their cabinets looking their best without a lot of effort.

brushed stainless steel cupboard door handles. This makes them a practical choice for busy homeowners who want to keep their cabinets looking their best without a lot of effort.