high tensile galvanized wire

Latest articles

Electric welding net welding after galvanized is after the completion of the welding and then cold galvanized or hot galvanized; After the first galvanized welding is to change the wire welding mesh, welding can be seen after the completion of the welding spot; The two processes are different prices are also very different, the cost of the first plating after welding is low, the surface is smooth, and the cost of the first welding after plating is higher, not easy to rust.

high tensile galvanized wire...

high tensile galvanized wire 【high tensile galvanized wire】

Read More

high tensile galvanized wireThe main customers of the barbed rope factory are still targeted at the farm and plantation customers for sales, because the demand for barbed rope is often very large.

...

high tensile galvanized wire 【high tensile galvanized wire】

Read Morehigh tensile galvanized wire

...

high tensile galvanized wire 【high tensile galvanized wire】

Read MoreThe galvanized requirements of the parts to be plated: the surface of the parts to be plated should be smooth, and there is no dirt that cannot be removed by pickling method. Such as paint, grease, cement, asphalt and excessive rotten harmful substances; All welds of welded components shall be sealed without air; Pipe fittings and containers must have exhaust and zinc inlet holes; The workpiece should be finished welded steel pipe without thread, if any thread should be protected.

high tensile galvanized wire...

high tensile galvanized wire 【high tensile galvanized wire】

Read Morehigh tensile galvanized wire

...

high tensile galvanized wire 【high tensile galvanized wire】

Read More

high tensile galvanized wireThe barbed rope is twined and braided to save transportation space. It is usually wound into bundles.

...

high tensile galvanized wire 【high tensile galvanized wire】

Read MoreThe common barbed rope produced by the manufacturer is the 14*14 type of barbed rope product. Since the warp wire used is the same as the wire diameter of the barbed rope, it is easier to calculate the length and weight. Usually each kilogram of barbed rope can reach about 10 meters of service length. The length of each kilogram of raw material is about 35 meters. Since 35 meters of raw material wire diameter can produce 10 lengths of barbed rope cost.

high tensile galvanized wire...

high tensile galvanized wire 【high tensile galvanized wire】

Read More

high tensile galvanized wireGalvanized barbed wire (barbed wire) is made of galvanized barbed wire twisted on the main wire, so as to play a protective and isolation role. Among them twist weave way is divided into single twist weave and double twist weave. Construction methods include direct installation and spiral insertion.

...

high tensile galvanized wire 【high tensile galvanized wire】

Read More

high tensile galvanized wire

Post time: 23-02-23...

high tensile galvanized wire 【high tensile galvanized wire】

Read More2.0*2.0mm 12 meters per kilogram

high tensile galvanized wire...

high tensile galvanized wire 【high tensile galvanized wire】

Read More

Popular articles

Latest articles

-

Post time: 10-03-23 -

-

Three is to do a good job of galvanized silk product production site clean and tidy, in accordance with the scientific method of operation to operate the production, the operator should wear the required dress. If it is hot dip galvanized wire products, we must do a good job of passivation treatment, will be able to effectively prevent discoloration, prolong the method of discoloration, can solve the problem of discoloration.

-

Three, the use of different technologies

-

-

Moreover, the double lip oil seal's design allows for some degree of self-lubrication, further enhancing its durability and reducing friction during operation Moreover, the double lip oil seal's design allows for some degree of self-lubrication, further enhancing its durability and reducing friction during operation

Moreover, the double lip oil seal's design allows for some degree of self-lubrication, further enhancing its durability and reducing friction during operation Moreover, the double lip oil seal's design allows for some degree of self-lubrication, further enhancing its durability and reducing friction during operation double lip oil seal.

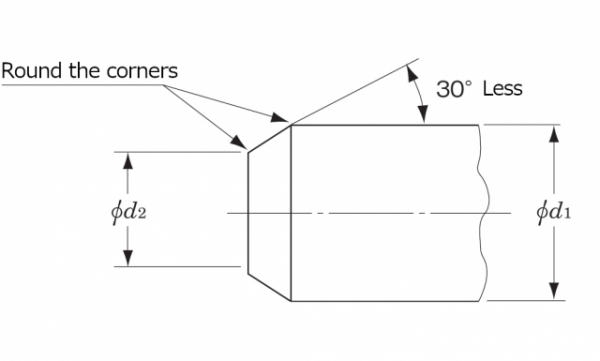

double lip oil seal.Oil seals are used to fill gaps between stationary and revolving parts of equipment, often known as radial shaft seals or rotary seals. These seals are frequently employed to keep impurities out and prevent lubricating oils, hydraulic fluids, or other liquids from escaping out of the system. An oil seal features:

Hopefully after reading this article, you have a better understanding of why choosing the right materials for oil seals is so important. Remember, if you have any questions about industrial oil seals and supplies, please contact us and we would be more than happy to help.

Heat resistance

Oil seals work by squeezing and retaining lubricant in a thin layer between the lip and the shaft. Perfect sealing is ensured by the hydrodynamic action of the rotating shaft, which in turn produces a slight pump action.

How to Choose the Right Oil Seal