16 common nail

Latest articles

16 common nailCold galvanizing (galvanizing) is in the plating tank after the current unidirectional, so that the zinc gradually plated on the metal surface, slow production speed, uniform coating, thin thickness, usually as long as 3-15g, bright appearance, poor corrosion resistance, usually a few months will rust. Compared with hot dip galvanizing, the production cost of electric galvanizing is lower.

...

16 common nail 【16 common nail】

Read More16 common nail

...

16 common nail 【16 common nail】

Read MoreThe smaller the mesh of decorative hook mesh, the finer the demand wire, the larger the mesh, the thicker the demand wire. For example, 6.5cm mesh aperture, the required iron diameter is 3.5mm-4mm. Then a fine welding will be broken, and then thick and heavy, workers can not bear.

16 common nail...

16 common nail 【16 common nail】

Read More16 common nail

...

16 common nail 【16 common nail】

Read More16 common nail

...

16 common nail 【16 common nail】

Read More

16 common nailThere is no adhesion test of powder spraying or fluorocarbon spraying on packaged galvanized wire, but there are two points for reference: first, in sealed or air-free environment, non-metallic volatiles can corrode zinc coating; Second, zinc at higher than 230 degrees (c) will cause the matrix metal brittle. And powder spraying and fluorocarbon spraying are to be baked at a higher temperature and in a sealed environment, causing rapid corrosion of zinc, resulting in loose corrosion film resulting in coating adhesion decline, and even lead to (matrix) steel wire brittle situation may exist.

...

16 common nail 【16 common nail】

Read More

16 common nail

Post time: 31-05-22...

16 common nail 【16 common nail】

Read MoreC, coating uniformity: galvanized layer is basically uniform with copper sulfate solution test etched five times without exposing iron.

16 common nail...

16 common nail 【16 common nail】

Read More16 common nail

...

16 common nail 【16 common nail】

Read More16 common nail

...

16 common nail 【16 common nail】

Read More

Popular articles

Latest articles

Links

- Overall, the use of floor marking tape is an essential part of any comprehensive safety management plan. By clearly defining designated areas and pathways, it helps to reduce the risk of accidents and injuries in the workplace. With its high visibility, durability, and ease of use, it's no wonder that floor marking tape has become a must-have tool for businesses of all sizes.

7. Easy to use: a layer of Self Fusing tape can play a good insulation role and reduce labor and cost.

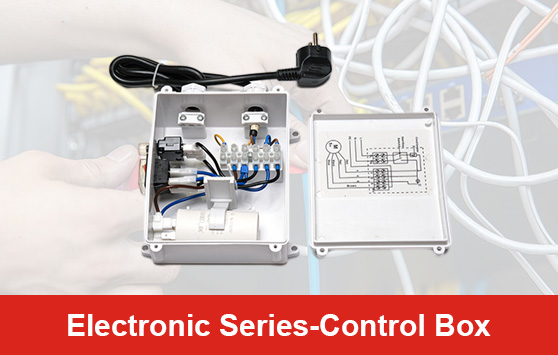

You can also find many more in-depth studies of what makes a good control box online. They’ll help you get a good idea of how to design component spacing, wireways and more. Next up, we’ll take a look at what some of the different types of control boxes look like and how they function.

flex tape in white.

In addition to their insulating properties, door bottom seal rubber strips also help to protect floors and carpets from moisture and dirt. By preventing water from seeping under the door, these strips can help to prevent water damage and mold growth. They also help to keep out dust and allergens, improving indoor air quality and reducing the risk of respiratory problems.